Mining Dump Steering Cylinder Hydraulics On Trucks

Mining Dump Steering Cylinder Hydraulics On Trucks

The steering cylinder for mining dump trucks is a vital hydraulic component engineered explicitly for optimal vehicle control in rugged mining environments. This cylinder ensures precise steering and exceptional maneuverability, allowing operators to navigate challenging mining sites with confidence.

Designed for durability and reliability, our mining dump truck steering cylinder significantly improves vehicle control, safety, and handling. By following proper usage guidelines and adhering to recommended maintenance practices, operators can maximize the longevity and performance of this essential component.

Invest in our high-performance steering cylinder to enhance your mining dump truck’s capabilities and streamline your mining operations. Experience improved steering precision and operational efficiency today!

Mining Dump Steering Cylinder Hydraulics On Trucks Parameter:

| Product Name | Mining Dump Steering Cylinder Hydraulics On Trucks |

| Features: | Wheel steering provides assistance |

| Bore diameter: | 63mm~210mm |

| Rod diameter: | 40mm~100mm Stroke≤2000mm |

| Thrust force: | Maximum779KN (Bore diameter 210mm/pressure22.5MPa) |

| Steering Cylinder Applications: | Mining Dump Truck |

Mining Dump Steering Cylinder Hydraulics On Trucks Characteristics:

坚固的结构

Our mining dump truck steering cylinder features a durable design crafted from high-quality materials and precision engineering. Built to endure the harsh conditions of mining environments, this cylinder ensures exceptional durability and a long service life.

Enhanced Steering Control:

Experience superior steering control with our hydraulic cylinder, allowing operators to maneuver mining dump trucks with precision and ease. It delivers the necessary force and responsiveness to navigate challenging terrains and heavy loads, ensuring smooth and accurate steering.

Optimal Maneuverability:

This steering cylinder enhances the vehicle’s maneuverability, making negotiating tight turns and confined spaces easier. Operators can maintain control and maximize productivity, even in the most demanding mining conditions.

Mining Dump Steering Cylinder Hydraulics On Trucks Identification Diagram:

How To Install Hydraulics On A Truck?

Installing hydraulics on a truck involves several key steps. Here’s a concise guide to help you through the process:

Gather Materials and Tools

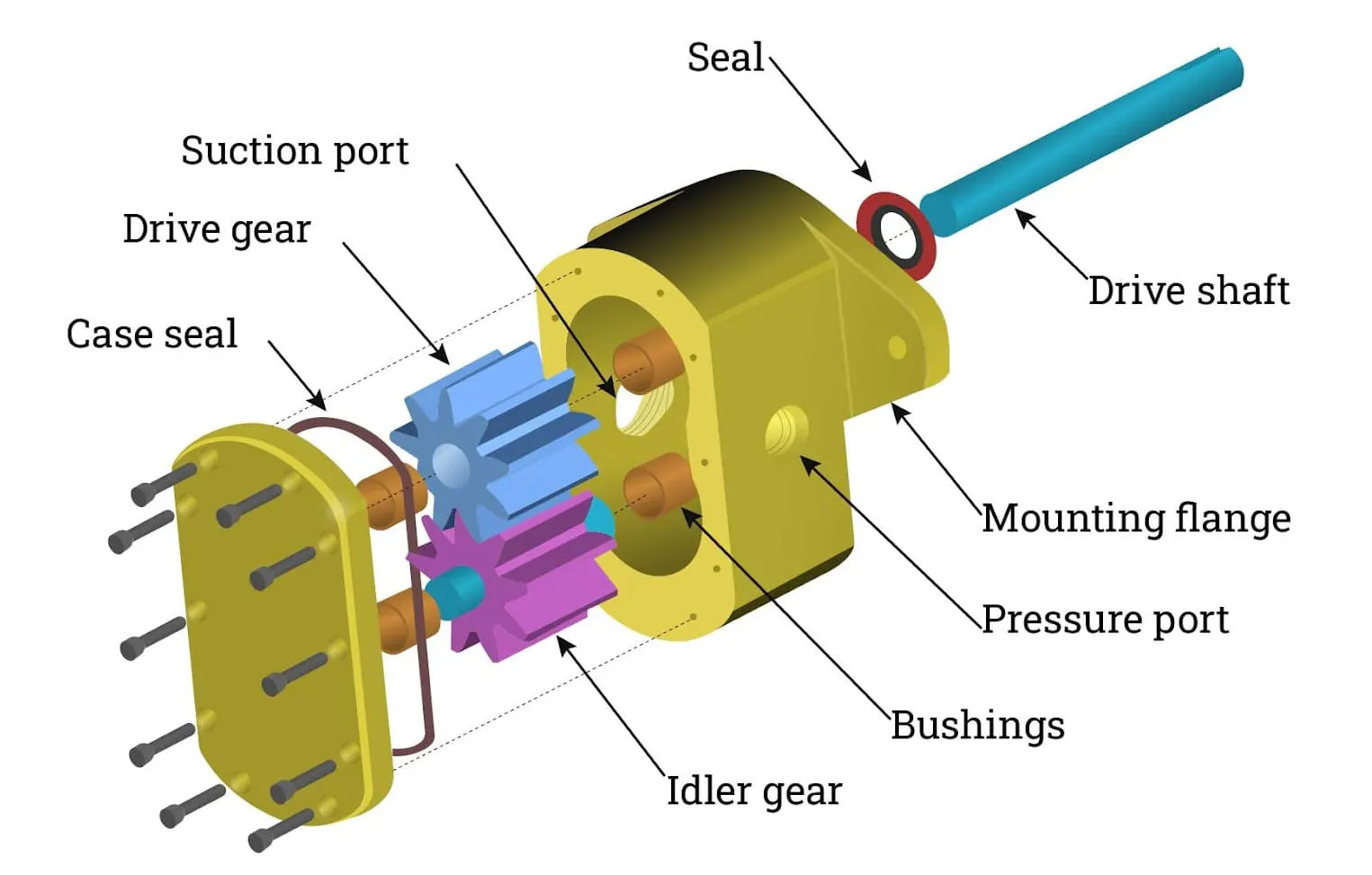

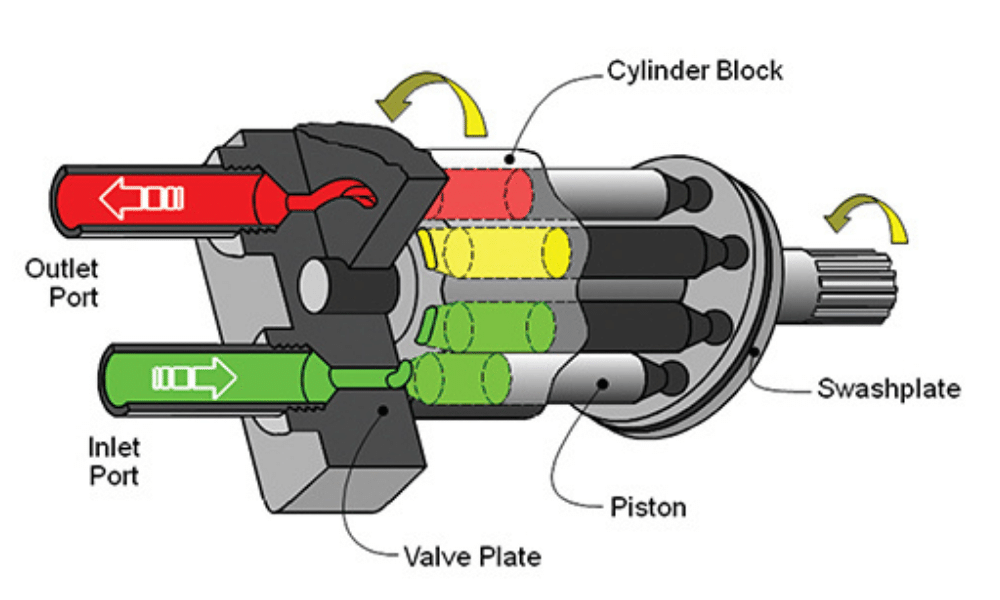

Hydraulic Components: Pump, cylinder, hoses, fittings, reservoir.

Tools: Wrenches, screwdrivers, drill, saw (if needed), hydraulic fluid.Plan the Installation

Choose Locations: Determine where to mount the pump, reservoir, and cylinder.

Review Schematics: Understand the connections and layout for your specific system.Install the Hydraulic Pump

Mount the Pump: Secure it to the truck frame or engine.

Align with PTO: Connect the pump to the power take-off if needed.Install the Hydraulic Reservoir

Position the Reservoir: Place it near the pump for easy access.

Secure it: Use brackets or bolts to attach it to the frame.Install the Hydraulic Cylinder

Mount the Cylinder: Secure it in the desired location (e.g., dump bed).

Ensure Stability: Ensure it’s firmly attached to the frame or bed.Run Hydraulic Hoses

Connect Hoses: Attach hoses from the pump to the cylinder and reservoir.

Use Proper Fittings: Ensure all connections are tight and leak-free.Connect Control Valves

Install Control Valves: Position them in the cab or near the driver’s seat.

Connect to Hydraulic Lines: Attach them to the hoses leading to the cylinder.Fill the Hydraulic System

Add Hydraulic Fluid: Fill the reservoir with the appropriate fluid.

Check for Leaks: Inspect all connections for any signs of leakage.Test the System

Operate the Controls: Test the hydraulic system to ensure functionality.

Monitor Performance: Watch for leaks and ensure smooth operation.Final Adjustments

Secure All Components: Ensure everything is tightly fastened.

Make Adjustments: Fine-tune any parts as necessary.

How To Adjust A Hydraulic Pump On A Dump Truck?

Adjusting a hydraulic pump on a dump truck involves several steps to ensure optimal performance. Here’s a guide to help you through the process:

安全第一

Wear Safety Gear: Use gloves, goggles, and protective clothing.

Park the Truck: Ensure the truck is on a flat surface and the engine is off.Locate the Hydraulic Pump

Identify the hydraulic pump, usually mounted on the engine or frame.

Check the Hydraulic Fluid

Inspect Fluid Level: Ensure the hydraulic reservoir is filled to the recommended level.

Check Fluid Condition: Look for contamination or discoloration; replace if necessary.Identify Adjustment Points

Locate Adjustment Screws: Check the pump manual for specific adjustment points, typically pressure relief and flow control screws.

Adjust the Pressure

Use a Pressure Gauge: Connect a hydraulic pressure gauge to the system.

Start the Engine: Allow the hydraulic system to pressurize.

Adjust the Relief Valve: Turn the adjustment screw clockwise to increase pressure or counterclockwise to decrease it. Make small adjustments and monitor the pressure gauge.Adjust the Flow Rate (if applicable)

Locate Flow Control Valve: This may be a separate valve on the pump.

Adjust the Flow Rate: Turn the flow control screw to increase or decrease flow, following the pump specifications.Test the System

Operate the Dump Bed: Raise and lower the dump bed to test the adjustments.

Monitor Performance: Observe the response time and pressure readings.Make Final Adjustments

Repeat the pressure and flow adjustments until the desired performance is achieved.

Check for Leaks

Inspect all connections and hoses for leaks after adjustments.

Record Settings

Document the final pressure and flow settings for future reference.

How To Check Hydraulic Fluid On Dump Truck?

Safety First:

Park the dump truck on a flat, stable surface.

Engage the parking brake and turn off the engine.Locate the Hydraulic Reservoir:

Find the hydraulic fluid reservoir, usually marked and positioned near the hydraulic system components.

Inspect the Fluid Level:

Check if there’s a dipstick or a sight glass on the reservoir.

If using a dipstick, remove it, wipe it clean with a cloth, and reinsert it to check the level.

If there’s a sight glass, simply observe the fluid level directly.Check Fluid Condition:

Assess the fluid’s color and clarity. Hydraulic fluid should be relatively clean and clear. If it appears dark or contains debris, it may need replacing.

Add Hydraulic Fluid if Necessary:

If the fluid level is low, add the recommended type of hydraulic fluid until it reaches the proper level. Ensure you use the fluid specified by the manufacturer.

Check for Leaks:

Inspect the area around the reservoir and hoses for any signs of leaks or damage.

Close the Reservoir:

If you added fluid, ensure the reservoir cap is securely replaced.

Test the System:

Start the truck and briefly operate the hydraulic system to circulate the fluid. Then recheck the fluid level to ensure it remains at the correct level.

工厂的能力和产能:

(1) 装配

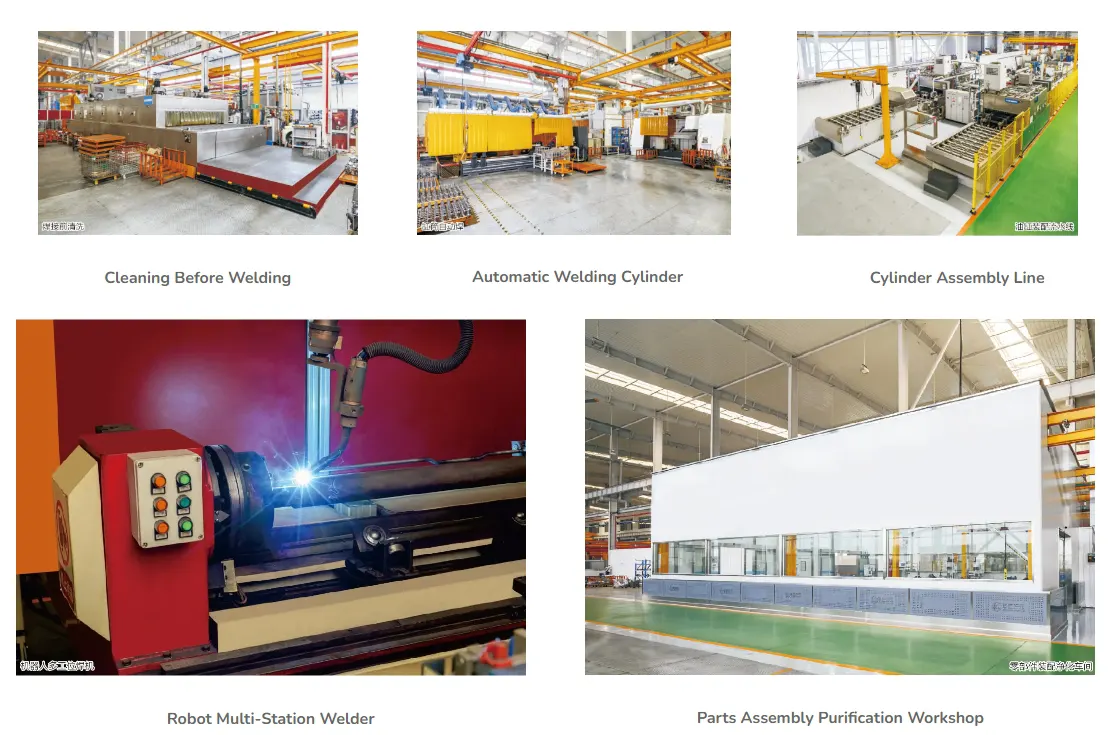

Our facility boasts a top-tier independent research and development assembly platform dedicated to hydraulic cylinder production. We operate four semi-automatic lifting cylinder assembly lines and one fully automatic tilt cylinder assembly line, with an impressive annual production capacity of 1 million cylinders.

In our specialized cylinder workshop, we utilize a semi-automatic cleaning assembly system designed for various specifications, capable of producing 200,000 cylinders annually. Our workshop is equipped with advanced CNC machining equipment, a machining center, high-precision cylinder processing tools, robot welding machines, automatic cleaning systems, and an automated cylinder assembly line. Additionally, we have a fully automated painting production line.

With over 300 pieces of critical equipment, our optimal resource allocation ensures that we meet the strict accuracy and quality standards required by our clients. This commitment to efficiency and precision positions us as a leader in the hydraulic cylinder industry.

(2) 机加工

Our machining shop features state-of-the-art equipment, including a customized inclined rail turning center, a precision machining center, a high-speed honing machine, and advanced welding robots. This sophisticated setup enables us to efficiently process cylinder tubes with a maximum inner diameter of 400mm and a length of up to 6 meters.

With our cutting-edge technology, we ensure high-quality machining that meets the diverse needs of hydraulic cylinder production.

(3) 焊接

(4) Painting & Coating

Our facility features advanced automatic water-based paint coating lines specifically designed for small and medium-sized cylinders. These lines utilize robotic technology for efficient loading, unloading, and spraying, achieving a remarkable production capacity of 4,000 pieces per shift.

In addition, we operate a semi-automatic paint production line for large cylinders, powered by a robust power chain, with a designed capacity of 60 cases per shift. This combination of automation and efficiency ensures high-quality finishes for all our hydraulic cylinders.

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are a renowned manufacturer of 液压缸, recognized as one of the best in the industry. Our extensive product line includes a wide range of hydraulic cylinders tailored to meet various applications. In addition to hydraulic cylinders, we also provide high-quality agricultural gearboxes, ensuring our customers have access to comprehensive solutions for their machinery needs.

With a commitment to excellence, we have successfully exported our products to clients worldwide, earning a strong reputation for superior product quality and exceptional after-sales service. Our dedication to customer satisfaction has positioned us as a trusted partner in both domestic and international markets.

Why Choose Us?

Professional Expertise: Our team comprises industry professionals with extensive knowledge and experience in hydraulic systems, ensuring that we deliver top-notch products and services.

International Certifications: We adhere to strict quality standards and hold various international certifications, demonstrating our commitment to delivering reliable and safe hydraulic solutions.

Custom Solutions: We understand that each customer’s needs are unique. That’s why we offer customized hydraulic cylinders and gearboxes tailored to meet specific requirements.

Advanced Production Equipment: Our state-of-the-art manufacturing facilities utilize the latest technology and equipment, enabling us to produce high-quality products efficiently.

Comprehensive After-Sales Support: Our commitment to our customers extends beyond the sale. We provide ongoing support and maintenance services to ensure optimal performance of our products.

We invite customers from around the globe to reach out to us for business negotiations, information exchange, and collaboration opportunities. Together, we can achieve greater success in the hydraulic industry!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: