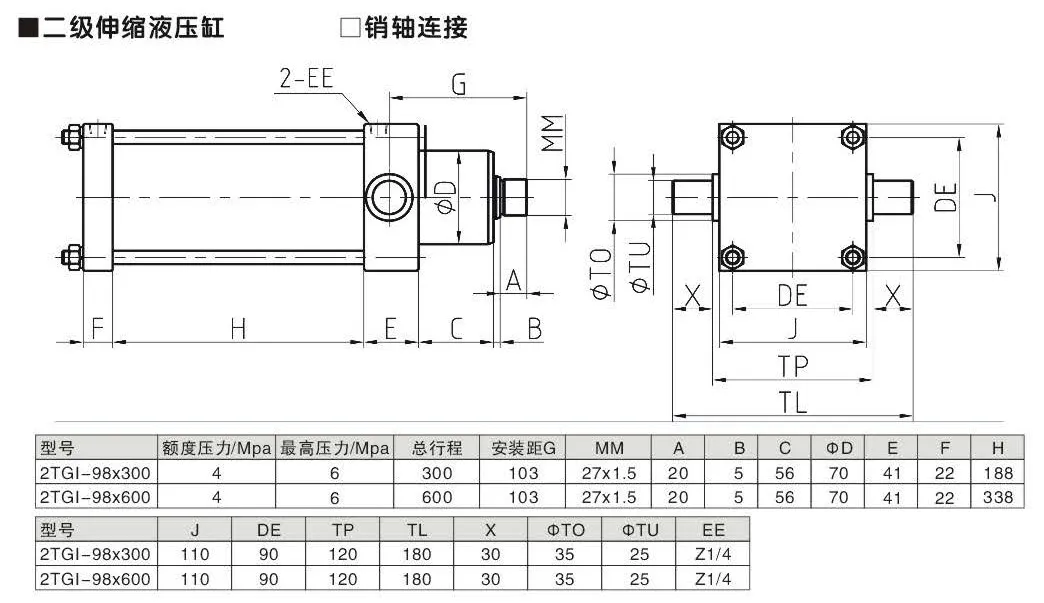

Pin Joint Two Stage Telescopic Hydraulic Cylinder

Pin Joint Two Stage Telescopic Hydraulic Cylinder

The pin joint two-stage telescopic hydraulic cylinder is a cutting-edge hydraulic element designed to provide efficient and reliable power transmission for a variety of industrial applications. With its innovative design, superior performance, and versatility, this hydraulic cylinder offers precise control and increased productivity. Whether used in construction, agriculture, or material handling, pin jonint two-stage telescopic hydraulic cylinders are designed to optimize the hydraulic operation and provide superior results.

CX series compact cylinders are used for clamping cylinders. Its installation is small. Our factory has advanced hydraulic equipment, including a vertical and horizontal machining center and medium and large hydraulic cylinders. Thin cylinder production technology is excellent.

Pin Joint Two Stage Telescopic Hydraulic Cylinder Parameter:

Pin Joint Two Stage Telescopic Hydraulic Cylinder Key Features and Benefits:

- Two-Stage Telescopic Design:

- The Pin Joint Two Stage Telescopic Hydraulic Cylinder features a two-stage telescopic design that increases stroke length while maintaining a compact retracted size.

- This design provides flexibility in hydraulic applications where extended reach is required without sacrificing space constraints.

- Pin Joint Construction:

- The cylinder incorporates pin joint construction, which enables smooth and synchronized movement of the telescopic stages.

- The pin joint mechanism ensures operation stability, precision, and excellent load-bearing capacity.

- Precise Control:

- This hydraulic cylinder offers exceptional control over extension and retraction, allowing precise positioning and efficient operations.

- The precise control mechanism ensures smooth and controlled movement, enhancing overall productivity.

- High Load-Bearing Capacity:

- The Pin Joint Two Stage Telescopic Hydraulic Cylinder is engineered to handle heavy loads and demanding industrial applications.

- It provides excellent load-bearing capacity, making it suitable for lifting, pushing, or pulling substantial weights.

Pin Joint Two Stage Telescopic Hydraulic Cylinder Usage Method:

- Mounting and Installation:

- Determine the appropriate installation location for the pin joint secondary telescopic hydraulic cylinder based on the specific requirements of your equipment or machine.

- Ensure that the mounting surface is strong, level, and can safely support the weight and load of the cylinder.

- Hydraulic System Connection:

- Connect the hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Align and secure the connections properly to prevent leaks and ensure optimal performance.

- Operating the Cylinder:

- Start the hydraulic system and start the movement of the two-stage telescopic hydraulic cylinder of the pin joint.

- The hydraulic control system is used to precisely control the extension of the cylinder and improve the operating efficiency.

How To Replace Seals In Hydraulic Cylinder?

To remove a hydraulic cylinder from a chair, follow these steps:

- Prepare the Workspace:

- Clear the area around the chair to create a safe and unobstructed workspace.

- Place a protective covering or cloth on the floor to prevent damage to the chair or surrounding surfaces.

- Lower the Chair:

- Use the chair’s adjustment lever or control mechanism to lower it to its lowest position.

- This step ensures that the cylinder is fully compressed, making removing it easier.

- Locate the Cylinder:

- Identify the hydraulic cylinder on the chair. It is typically located near the chair’s base and connects to the seat or the chair’s mechanism.

- Remove the Chair Seat:

- If the chair seat is detachable, locate the mounting screws or bolts that secure it to the cylinder or chair base.

- Use the appropriate tool, such as a screwdriver or wrench, to remove the screws or bolts.

- Lift the seat off the chair, exposing the hydraulic cylinder.

- Support the Chair:

- Since the chair will be unstable without the seat, provide support to prevent it from tipping over.

- Use a sturdy object, such as a box or a wooden block, to prop up the chair’s remaining structure.

- Disconnect the Cylinder:

- Examine the connection points between the hydraulic cylinder and the chair mechanism or base.

- Depending on the chair design, you may find mounting brackets, clips, or screws securing the cylinder.

- Remove any fasteners holding the cylinder in place using the appropriate tools.

- Once the fasteners are removed, gently pull or wiggle the cylinder to detach it from the chair.

- Replace or Dispose of the Cylinder:

- If you are replacing the hydraulic cylinder, ensure you have a compatible replacement that matches the specifications of the old cylinder.

- If necessary, consult the chair manufacturer or a professional to obtain the correct replacement cylinder.

- If you are disposing of the cylinder, follow your local regulations and guidelines for proper disposal.

- Reassemble the Chair:

- Reattach the chair seat by aligning the screw holes and securing them with the appropriate screws or bolts if you removed the chair seat.

- Ensure the seat is firmly attached and stable before using the chair again.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best compact hydraulic cylinder manufacturers. We can offer comprehensive compact hydraulic cylinder stock. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: