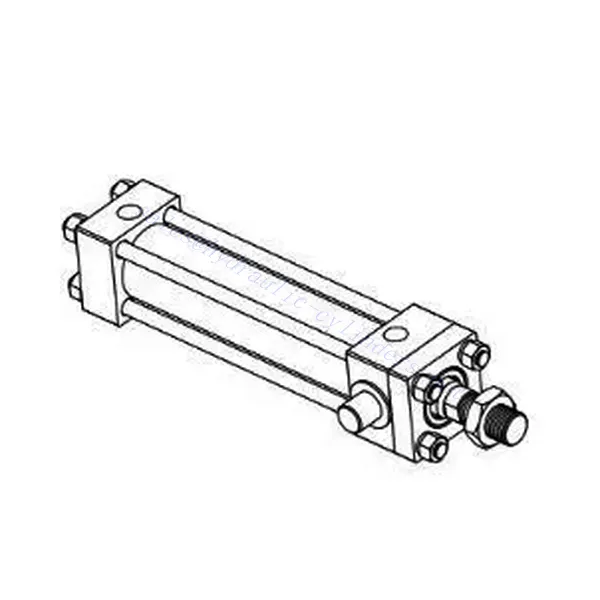

TA 前耳轴式重杆液压缸

TA 前耳轴式重杆液压缸

The TA front trunnion-type heavy rod hydraulic cylinder is a powerful and reliable hydraulic element that performs well in various industrial applications. With its robust construction, precise engineering, and advanced features, this hydraulic cylinder can stand out in demanding tasks that require force and precision. From heavy machinery to material handling equipment, TA front trunnion-type heavy rod hydraulic cylinders are designed to provide optimal power, control, and durability in various industrial environments.

Heavy Rod Hydraulic Cylinder Key Characteristics:

坚固的结构 TA front trunnion-type heavy rod hydraulic cylinders feature a full design with high-quality materials such as steel or alloys to withstand heavy loads, extreme pressures, and harsh operating conditions. Its rugged construction ensures long-lasting durability and resistance to wear, corrosion, and damage.

High Force Output: This heavy rod hydraulic cylinder is designed to provide superior force output, making it ideal for applications involving heavy lifting, pushing, or pulling. Its large piston diameter and high-pressure capability give it the strength to handle demanding tasks easily.

Precise Control: TA front trunnion type heavy rod hydraulic cylinder provides precise control over the movement and positioning of the load. Its advanced design combines precision machined components, high-quality seals, and smooth rod surfaces to ensure accurate and reliable operation.

Front Trunnion Mounting: The heavy rod hydraulic cylinder is designed with a front trunnion mounting system, which provides a safe and flexible mounting option. Front trunnion mounting allows easy integration into various hydraulic systems and equipment configurations.

TA Front Trunnion Type Heavy Rod Hydraulic Cylinder Parameter:

TA 前耳轴式重杆液压缸 Usage Method:

Mounting: First, safely install the TA front trunnion-type heavy rod hydraulic cylinder into the designated position using the appropriate mounting brackets or fixtures. Ensure proper alignment and stability during installation to prevent cylinder misalignment or stress.

Hydraulic System Integration: Follow the manufacturer’s instructions and guidelines to connect hydraulic lines to cylinder ports. The cylinder is integrated into the hydraulic system by clicking it to a suitable pump or power unit. Ensure cylinder specifications and operating requirements are met.

Control and Operation: The control valve in the hydraulic system regulates the flow of hydraulic oil into and out of the cylinder. Adjust the control Settings according to the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

TA 前耳轴式重杆液压缸 Maintenance:

Regular maintenance ensures optimal performance and service life of TA front trunnion-type heavy rod hydraulic cylinders. Here are some maintenance suggestions:

Regular Inspection: Perform routine inspections to identify any signs of wear, damage, or leaks. Check for abnormalities in cylinder blocks, piston rods, seals, and other components. Resolve any issues promptly to prevent further injury or operational inefficiencies.

Lubrication: Apply the recommended lubricant to the moving parts of the cylinder, including tie rods and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation. Use the appropriate lubricant type according to the manufacturer’s lubrication interval guidelines.

Seal Replacement: If seals are found to be deteriorating or leaking, replace seals with genuine parts approved by the manufacturer. Damaged or worn seals can compromise the cylinder’s performance and lead to hydraulic oil leakage.

清洁: Clean cylinders by removing dirt, debris, and other contaminants. Before reassembling, use a non-abrasive cleaner and make sure all parts are completely dry. Regular cleaning promotes optimal performance and prevents premature wear or damage.

How To Replace Seals In A Hydraulic Cylinder?

Replacing seals in a hydraulic cylinder requires careful attention and proper procedure to ensure successful replacement. Here’s a step-by-step guide on how to replace seals in a hydraulic cylinder:

- Safety Precautions: Before starting any maintenance work, take appropriate safety precautions. Ensure the hydraulic system is depressurized and the equipment is adequately supported and secured. Wear protective gloves and safety glasses to protect yourself from any potential hazards.

- Cylinder Removal: Depending on the specific hydraulic system and cylinder design, you may need to remove the hydraulic cylinder from its mounting location. Follow the manufacturer’s instructions or consult the equipment manual for the proper procedure to remove the cylinder.

- Cylinder Disassembly: Once the hydraulic cylinder is removed, carefully disassemble it to access the seals. Typically, hydraulic cylinders consist of a cylinder barrel, piston, piston rod, and various seals. Follow these steps:a. Remove the Cylinder Head: Unscrew or unbolt the cylinder head from the barrel, exposing the piston and piston rod.b. Remove the Piston: Gently slide the piston out of the cylinder barrel. Be cautious to avoid damaging the piston or the cylinder walls.c. Remove the Old Seals: Identify the seals that need to be replaced, such as piston seals, rod seals, or wiper seals. Use appropriate tools, such as seal removal picks or hooks, to remove the old seals from their grooves. Take note of the seal orientation for proper installation of the new seals.

- Seal Preparation: Inspect the new seals for any defects or damage before installing them. Ensure that you have the correct replacement seals that match the specifications of the original ones. Apply a thin film of hydraulic oil or seal lubricant to the new seals to facilitate proper installation and reduce friction.

- Seal Installation:a. Piston Seals: Start by installing the new piston seals. Carefully position the seals into their grooves, ensuring they sit flush and are not twisted. Use a seal installation tool or soft-faced mallet to press the seals into place gently. Ensure that the seals are evenly seated and properly aligned.b. Rod Seals and Wiper Seals: Move on to installing the rod and wiper seals. Again, position the seals correctly in their grooves, ensuring they are not twisted. Apply gentle pressure using a seal installation tool or a mallet to secure the seals.

- Reassembly: Once all the new seals are installed, reassemble the hydraulic cylinder. Follow these steps:a. Reinstall the Piston: Carefully slide the piston back into the cylinder barrel, ensuring it moves freely without any obstruction. Align any retention mechanisms, such as snap rings or circlips, as necessary.b. Reattach the Cylinder Head: Place the cylinder head back onto the cylinder barrel and secure it with screws or bolts. Ensure proper tightening according to the manufacturer’s specifications.

- Cylinder Installation: If you removed the hydraulic cylinder from its mounting location, reinstall it following the appropriate procedure. Ensure proper alignment and connection to the hydraulic system, including the lines and fittings.

- Testing and Inspection: Test its functionality once the hydraulic cylinder is reinstalled. Gradually pressurize the system and check for any leaks, abnormal noises, or improper operation. Conduct a thorough inspection to ensure the seals are performing as intended.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

我们是最好的重型连杆液压缸制造商之一。我们可以提供广泛的重型连杆液压缸库存。我们还提供相应的 农用齿轮箱.我们的产品已出口到世界各地,并凭借卓越的产品质量和售后服务赢得了良好的声誉。我们热忱欢迎海内外客户与我们联系,洽谈业务,交流信息,共谋发展。 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: