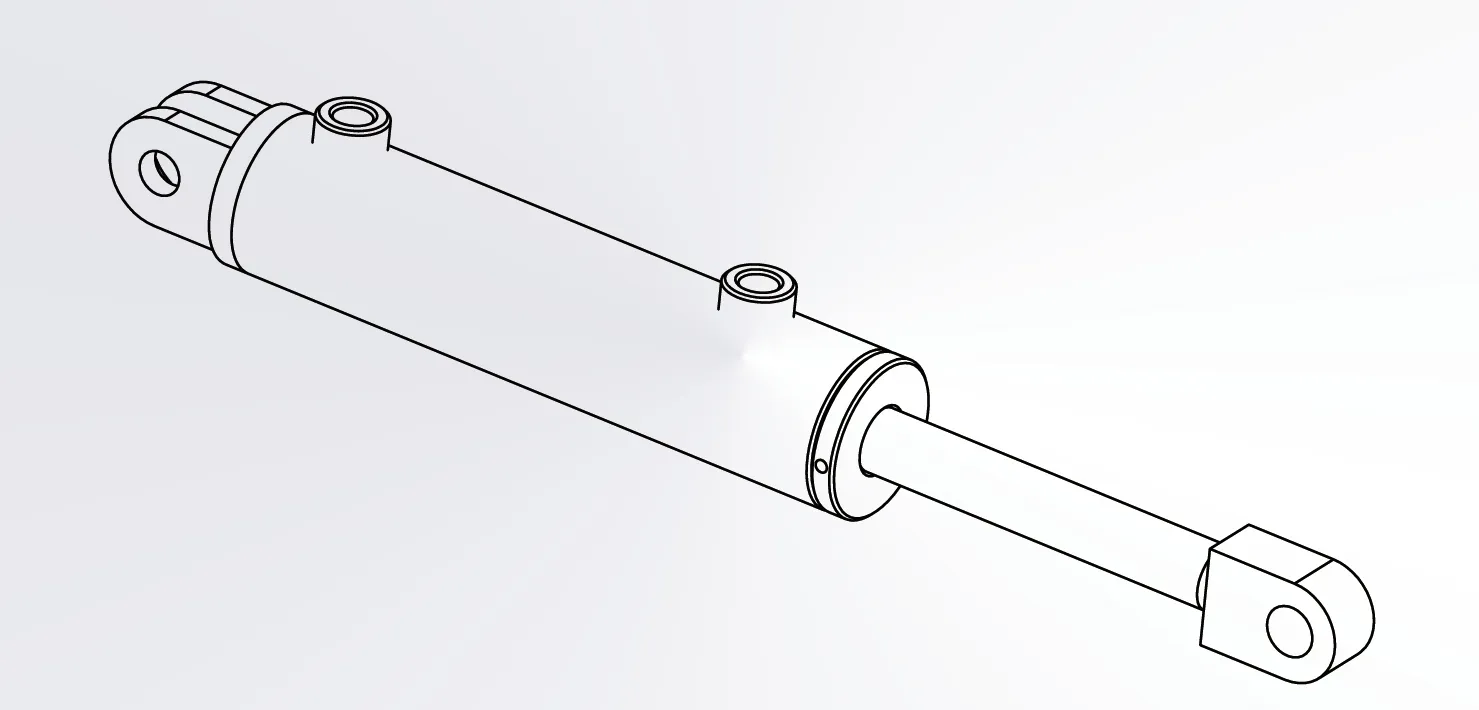

Steering Cylinder For Scissor Type Aerial Work Vehicles

Steering Cylinder For Scissor Type Aerial Work Vehicles

Huachang’s steering cylinder for scissor-type aerial work vehicles delivers unmatched precision and reliability for scissor lift platforms, empowering seamless navigation in demanding environments. Engineered for compact yet powerful performance, this hydraulic steering cylinder ensures smooth directional control, making it ideal for tight spaces in warehousing, construction, and facility maintenance. Designed to integrate seamlessly with leading scissor lift models, including those from global and Chinese manufacturers, our cylinders enhance operational efficiency and safety across diverse applications.

ISO-certified and backed by Huachang’s rigorous quality control, our cylinders meet international standards (ISO 9001, 14001, 45001), guaranteeing safety and performance. Whether navigating crowded job sites or supporting high-frequency operations, this scissor lift steering cylinder elevates productivity with its robust design and ease of maintenance. Trusted by aerial platform operators worldwide, Huachang delivers tailored solutions for the growing aerial work vehicle market, including China’s booming industry. Choose Huachang for high-performance hydraulic steering cylinders that set the standard for scissor lift reliability. to explore our solutions or request a quote today!

Steering Cylinder For Scissor Type Aerial Work Vehicles Parameter:

Function: Implement steering axle action and achieve scissor-type tire steering

Cylinder Diameter: 40mm-70mm

Rod Diameter: 20mm-40mm

Travel: 104mm-497mm

Maximum Pressure: 20 兆帕

Maximum Thrust: 77kN

Cylinder Series For Scissor Type Aerial Work Vehicles:

Key Features of Steering Cylinder For Scissor Type Aerial Work Vehicles:

Huachang’s steering cylinder for scissor type aerial work vehicles is engineered to deliver precise maneuverability and robust performance for scissor lifts in demanding environments. Designed for seamless integration with leading scissor lift platforms, these hydraulic cylinders ensure reliable steering control for warehousing, construction, and facility maintenance applications. Explore the key features that make our steering cylinders the ideal choice for enhancing aerial work platform efficiency.

- Precise Steering Control: This durable hydraulic steering cylinder for scissor lift enables smooth, responsive steering, allowing operators to navigate tight spaces with ease. Its advanced hydraulic design ensures accurate directional control, ideal for indoor warehousing or crowded construction sites requiring pinpoint precision.

- Compact and Robust Design: Built to fit the compact structure of scissor lifts, this hydraulic steering cylinder for aerial platform offers high strength in a space-saving design. Its sturdy construction ensures reliable performance under continuous use, supporting efficient operations in high-traffic environments.

- Durable Materials: Crafted from high-grade steel, this cylinder withstands harsh conditions, including dust, moisture, and temperature fluctuations. The reliable steering cylinder for scissor type aerial work vehicles minimizes wear, reducing maintenance costs for industries like facility management.

- Leak-Proof Seals: Equipped with advanced seals, this cylinder prevents hydraulic fluid leaks, ensuring consistent steering performance and lower maintenance downtime. The low-maintenance steering cylinder for scissor lift is designed for long-term reliability in demanding applications.

In addition to our lifting cylinder for arm type aerial work vehicles, Huachang provides a diverse range of aerial work vehicle hydraulic cylinders, including tilt, steering, and stabilizing cylinders for boom and scissor lifts. Designed for compatibility and performance, our solutions meet your unique needs. to find the perfect hydraulic system.

How Does The Behind Cylinder Improve Stability During Heavy Lifting Operations In Truck Cranes?

Certainly! Here’s an expanded and optimized response regarding the benefits of corrosion resistance in the HCYY11112004 Steering Cylinder:

1. Reduced Maintenance

The specialized protective coating on the HCYY11112004 significantly minimizes the risk of rust and wear. This reduction in corrosion leads to fewer maintenance requirements, allowing operators to dedicate more time to their core tasks rather than routine inspections or repairs. Consequently, the operational efficiency of the vehicle is enhanced, as downtime for maintenance is greatly reduced. This is particularly advantageous in high-demand environments where time is critical.

2. Increased Longevity

Corrosion resistance plays a crucial role in extending the lifespan of the HCYY11112004 Steering Cylinder. By preventing deterioration from environmental factors, the cylinder can withstand rigorous use over time. This longevity means operators can rely on the component for a more extended period without the need for frequent replacements, ultimately translating to significant cost savings. The investment in a durable product like the HCYY11112004 pays off by reducing the frequency of part replacements and associated labor costs.

3. Enhanced Reliability

The corrosion-resistant design ensures that the HCYY11112004 Steering Cylinder maintains its performance integrity, even in harsh conditions. Operators can trust that the cylinder will function reliably, whether exposed to moisture, extreme temperatures, or other challenging elements. This reliability is paramount in ensuring that aerial work vehicles operate smoothly, reducing the likelihood of unexpected breakdowns that could lead to safety hazards or project delays.

4. Improved Safety

With a durable, corrosion-resistant component, the risk of mechanical failures is significantly lowered. This is especially important in the aerial work industry, where safety is a top priority. A reliable steering cylinder contributes to the overall safety of operations, allowing operators to maneuver confidently in complex environments. By minimizing the chances of equipment failure, operators can focus on their work, knowing that their tools are dependable and robust.

In summary, the corrosion resistance of the HCYY11112004 Steering Cylinder not only enhances its durability and reliability but also contributes to reduced maintenance needs, increased longevity, and improved safety for operators in demanding work environments.

Aerial Work Vehicles Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing "load efficiency" and "internal leakage" through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: