Small Excavator Bucket Cylinder

Small Excavator Bucket Cylinder

The small excavator bucket cylinder is a high-performance hydraulic component designed to optimize small excavators’ digging and lifting capabilities. With its compact size and robust construction, this cylinder offers exceptional strength, precision, and durability.

The small excavator bucket cylinder is a robust and reliable hydraulic component that enhances the efficiency and versatility of small excavators. With its compact design, high lifting capacity, and precise control, this cylinder enables operators to tackle various excavation tasks quickly and precisely. By following the recommended usage methods and maintenance practices, operators can ensure optimal performance and longevity of the small excavator bucket cylinder, resulting in increased productivity and successful completion of construction and excavation projects. Invest in this exceptional hydraulic cylinder to elevate the capabilities of your small excavator and achieve superior results in your digging and lifting operations.

Small Excavator Bucket Cylinder Key Characteristics:

- Compact Design and Lightweight Construction

- The small excavator bucket cylinder is specifically engineered for small excavators, ensuring a perfect fit and optimal performance.

- Its compact design and lightweight construction minimize the overall weight of the excavator, enhancing maneuverability and fuel efficiency.

- High Lifting Capacity and Digging Force

- Despite its small size, the cylinder delivers impressive lifting capacity and digging force, allowing for efficient excavation and material handling.

- It enables the excavator to tackle a wide range of tasks, from digging trenches to clearing debris, quickly and precisely.

- Smooth Operation and Precise Control

- The cylinder’s advanced hydraulic system ensures smooth and precise operation, enabling accurate bucket positioning for efficient digging and loading.

- It offers excellent control over the excavator’s movements, allowing operators to work in tight spaces and achieve optimal results.

- Robust Construction and Durability

- The small excavator bucket cylinder is built with high-quality materials and rigorous manufacturing standards and exhibits exceptional strength and durability.

- It withstands demanding working conditions, including heavy-duty digging and frequent operation, ensuring reliable performance over an extended lifespan.

Small Excavator Bucket Cylinder Parameter:

| Product Name | Small Excavator Bucket Cylinder |

| Features: | Control the action of the bucket |

| Bore diameter: | 50mm~105mm |

| Rod diameter: | 25mm~70mm Stroke≤1000 mm |

| Thrust force: | Maximum 255KN |

| Bore diameter: | 105mm/pressure29.4MPa |

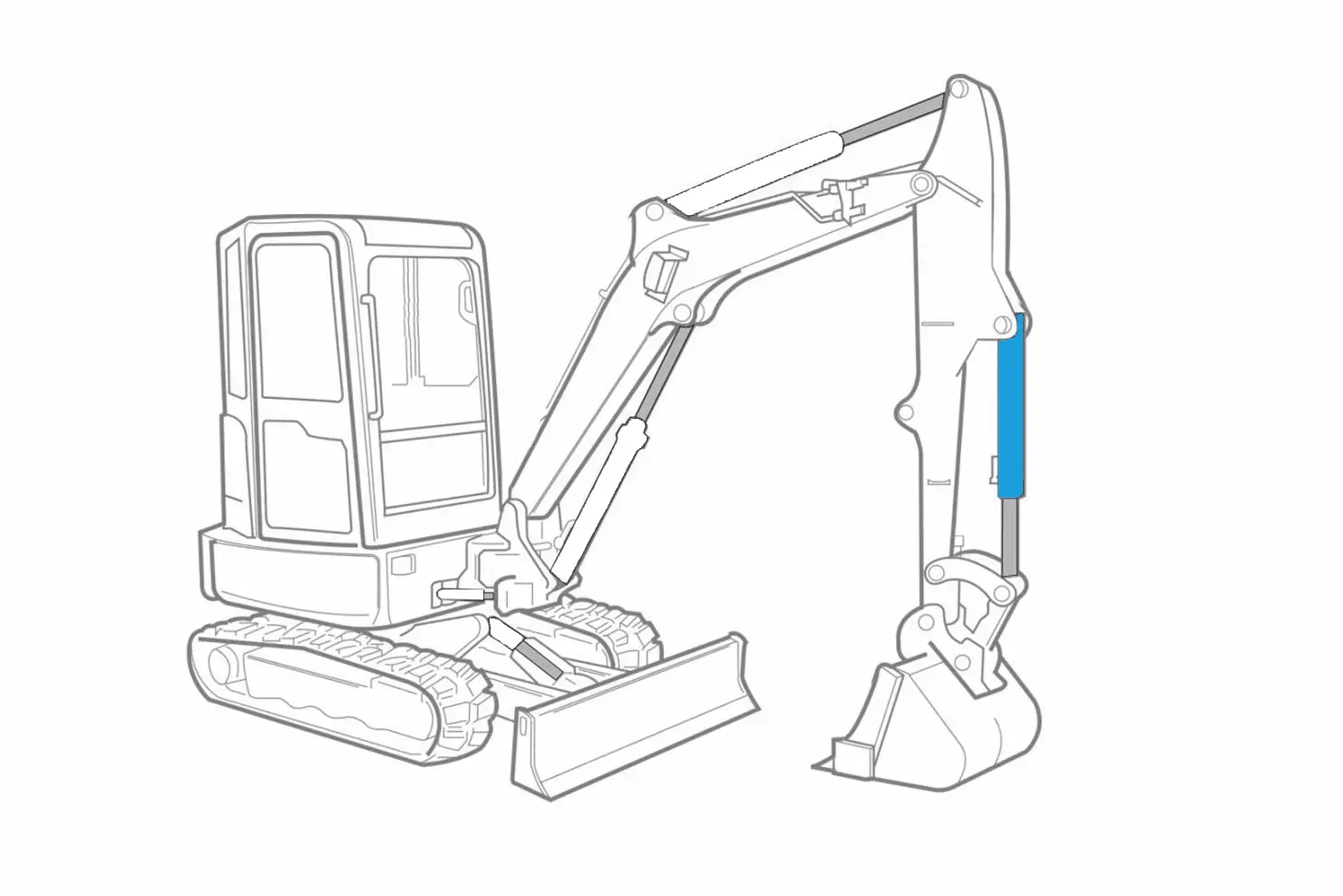

Small Excavator Bucket Cylinder Identification Diagram:

Maintenance Of Small Excavator Bucket Cylinder:

- 定期检查

- Conduct visual inspections of the small excavator bucket cylinder before each operation to identify any signs of leaks, damage, or wear.

- Check hydraulic connections, seals, and mounting points for tightness and integrity.

- Inspect the cylinder rod and cylinder body for signs of corrosion or scoring.

- Lubrication and Cleaning

- Follow the manufacturer’s recommendations for lubrication intervals and procedures.

- Apply suitable lubricants to the cylinder rod and seals to minimize friction and ensure smooth operation.

- Regularly clean the cylinder and surrounding components to remove dirt, debris, and contaminants affecting performance.

- Fluid Monitoring

- Regularly check the hydraulic fluid level in the excavator’s hydraulic system.

- Maintain the proper fluid level and quality according to the manufacturer’s specifications.

- Monitor the hydraulic system for any fluid contamination or degradation signs and address them promptly.

- Professional Servicing

- Schedule regular maintenance and servicing with qualified technicians.

- Seek professional assistance for any repairs, replacements, or troubleshooting needs of the small excavator bucket cylinder.

- Follow the recommended maintenance schedule to maximize the cylinder’s performance and longevity.

What Size Cylinder For Excavator Thumb?

The size of the cylinder for an excavator’s thumb can vary depending on the specific requirements of the excavator and the intended use of the thumb attachment. The appropriate size of the cylinder is typically determined by considering factors such as the excavator’s operating weight, the desired lifting capacity of the thumb, and compatibility with the excavator’s hydraulic system.

To determine the suitable cylinder size for an excavator thumb, it is recommended to consult the manufacturer or supplier of the thumb attachment. They can provide guidance based on the excavator’s specifications and the thumb’s intended application.

It’s worth noting that excavator thumbs are available in various sizes and configurations to accommodate different excavator models and sizes. The thumb attachment typically consists of a central structure or frame that mounts to the excavator’s boom and a hydraulic cylinder that provides the gripping or clamping action. The cylinder size should be selected to ensure compatibility with the thumb attachment and to provide the required gripping force for the intended tasks.

When considering the cylinder size for an excavator’s thumb, it’s essential to strike a balance between having sufficient lifting capacity and ensuring that the excavator’s hydraulic system can adequately support the operation of the thumb. Oversizing the cylinder may strain the excavator’s hydraulic system excessively, while under sizing, may result in limited lifting capacity and reduced performance.

In summary, the size of the cylinder for an excavator thumb should be determined based on factors such as the excavator’s operating weight, desired lifting capacity, and compatibility with the thumb attachment and hydraulic system. Consulting the manufacturer or supplier of the thumb attachment is recommended to ensure proper sizing and optimal performance.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinder. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: