Small Excavator Boom Cylinder

Small Excavator Boom Cylinder

The Small Excavator Boom Cylinder is a powerful hydraulic component that optimizes small excavators’ lifting and reaching capabilities. This cylinder is specifically engineered to deliver exceptional strength, durability, and precision in compact construction machinery.

The Small Excavator Boom Cylinder is a vital hydraulic component that enhances the efficiency and performance of small excavators. With its compact design, high lifting capacity, and precise control, this cylinder empowers operators to tackle various excavation tasks easily and precisely. By following the recommended usage methods and maintenance practices, operators can ensure optimal performance and longevity of the Small Excavator Boom Cylinder, resulting in increased productivity and successful completion of construction and excavation projects. Invest in this exceptional hydraulic cylinder to elevate the capabilities of your small excavator and achieve superior results in your lifting and reaching operations.

Small Excavator Boom Cylinder Key Characteristics:

- Compact Design and Robust Construction

- The Small Excavator Boom Cylinder is purpose-built for small excavators, ensuring a perfect fit and optimal performance.

- Its compact design and robust construction allow it to withstand rigorous operating conditions, providing long-lasting durability.

- High Lifting Capacity and Reach

- Despite its small size, the cylinder delivers impressive lifting capacity and reach, enabling efficient material handling and excavation tasks.

- It provides the necessary power and extension to maneuver in confined spaces and access hard-to-reach areas.

- Precise Control and Smooth Operation

- The cylinder’s advanced hydraulic system ensures precise control and smooth operation, allowing operators to perform tasks with accuracy and efficiency.

- It offers excellent responsiveness and maneuverability, facilitating precise positioning and enhanced productivity on the job site.

- Reliable Performance and Safety

- Built with high-quality materials and stringent manufacturing standards, the Small Excavator Boom Cylinder delivers reliable performance in demanding environments.

- It incorporates safety features that prevent sudden drops or unexpected movements, ensuring operator and equipment safety during operation.

Small Excavator Boom Cylinder Parameter:

| Product Name | Small Excavator Boom Cylinder |

| Features: | Control the lifting motion of the big arm |

| Bore diameter: | 50mm~125mm |

| Rod diameter: | 25mm~75mm Stroke≤1000mm |

| Thrust force: | Maximum 361KN |

| Bore diameter: | 125mm/pressure29.4MPa |

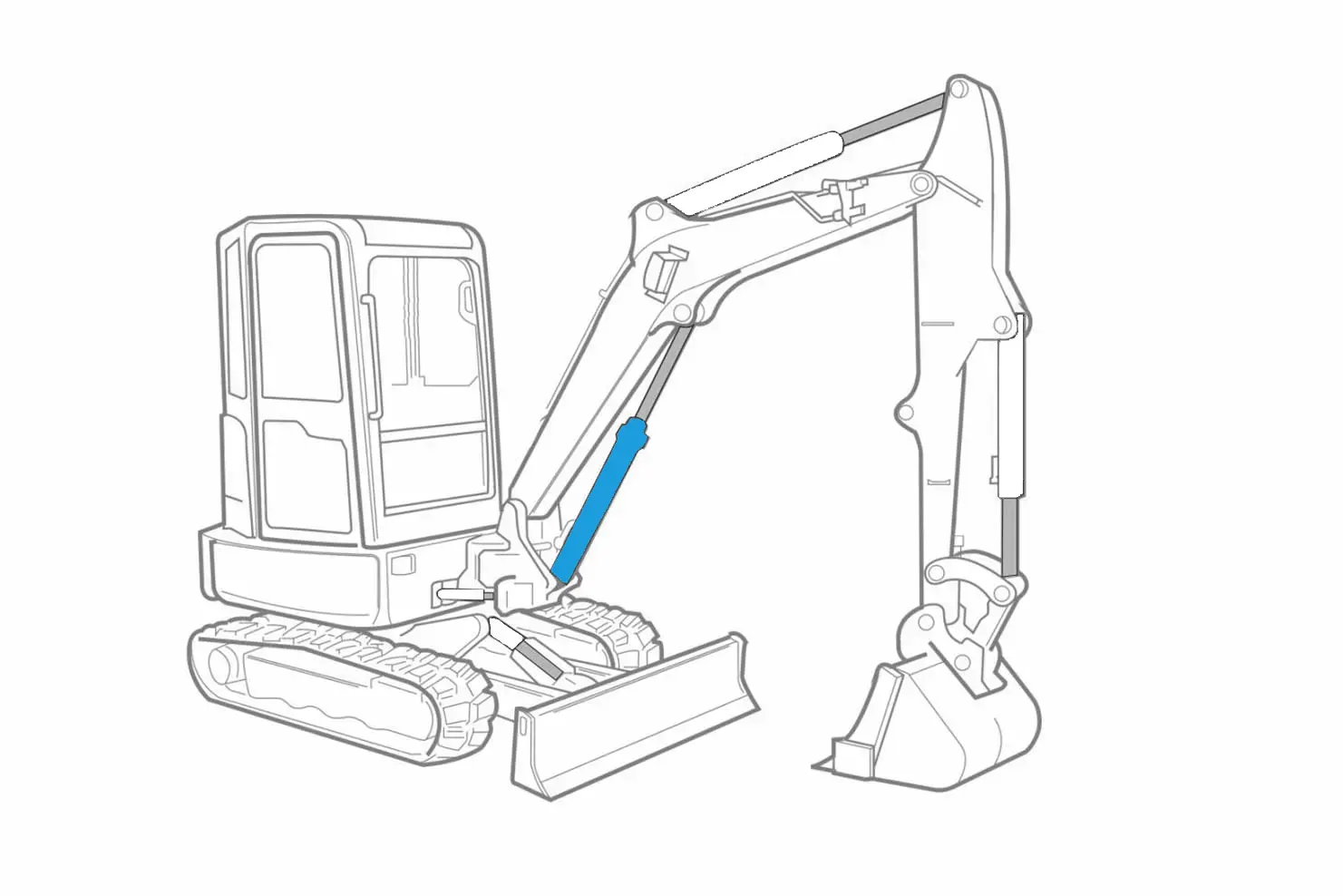

Small Excavator Boom Cylinder Identification Diagram:

Usage Method Of Small Excavator Boom Cylinder:

- Installation and Integration

- Consult the manufacturer’s instructions for proper installation of the Small Excavator Boom Cylinder.

- Ensure compatibility and secure attachment to the excavator’s boom assembly.

- Follow recommended torque specifications and use appropriate mounting hardware.

- Operational Considerations

- Familiarize yourself with the controls and operation of the excavator, including the boom cylinder.

- Practice operating the excavator and boom cylinder in a controlled environment before commencing actual work.

- Adhere to safety guidelines, operate within the excavator’s load, and reach limits to prevent accidents and equipment damage.

- Efficient Lifting and Reaching Techniques

- Utilize the Small Excavator Boom Cylinder’s precise control to optimize lifting and reaching techniques.

- Maintain a stable position while lifting or extending the boom, avoiding sudden or jerky movements that can strain the cylinder.

- Ensure proper positioning of the load and maintain balance for safe and efficient material handling.

How To Remove Hydraulic Cylinder From Excavator?

Removing a hydraulic cylinder from an excavator requires careful attention and adherence to proper procedures to ensure safety and prevent damage to the equipment. Here are general steps to guide you through the process:

- Preparation:

- Ensure the excavator is turned off and parked on a level surface.

- Engage the safety lock and secure the boom and arm in a stable position.

- Put on appropriate personal protective equipment, such as gloves and safety glasses.

- Identify the Cylinder:

- Locate the hydraulic cylinder you wish to remove. It may be attached to the boom, arm, or other excavator components.

- Relieve Hydraulic Pressure:

- Before disconnecting any hydraulic lines or fittings, it’s crucial to release the pressure in the system to prevent sudden movements or fluid spray.

- Start by locating your excavator model’s pressure relief valve or pressure release procedure.

- Follow the manufacturer’s guidelines to depressurize the hydraulic system properly.

- Disconnect Hydraulic Lines:

- Identify the hydraulic lines connected to the cylinder. These lines carry hydraulic fluid to and from the cylinder.

- Use appropriate wrenches or fittings to loosen and disconnect the hydraulic lines from the cylinder.

- Place a container or absorbent material beneath the disconnected lines to catch residual hydraulic fluid.

- Remove Mounting Hardware:

- Locate the mounting points of the cylinder. These may be bolts or pins securing the cylinder to the excavator’s structure.

- Use the appropriate tools to remove the mounting hardware depending on the specific design.

- Ensure proper support for the cylinder during removal to prevent it from falling or causing damage.

- Detach the Cylinder:

- Carefully slide or maneuver the cylinder out of its mounting position. If it’s tightly fitted, you may need to gently tap it with a rubber mallet or use a hydraulic cylinder puller for assistance.

- Ensure that no other components or structures are obstructing the cylinder’s removal.

- Inspection and Maintenance:

- Once the cylinder is removed, inspect it for any signs of damage, leaks, or wear.

- Clean the cylinder and inspect the rod, seals, and other components for any signs of corrosion, scoring, or excessive wear.

- Perform any necessary maintenance or repairs before reinstalling the cylinder.

- Reinstallation or Replacement:

- To reinstall the hydraulic cylinder, follow the reverse steps of the removal process, ensuring proper alignment and torque specifications.

- If the cylinder is being replaced, carefully install the new cylinder according to the manufacturer’s instructions and guidelines.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: