Mobile Crane Luffing Cylinder

Mobile Crane Luffing Cylinder

The mobile crane luffing cylinder is essential in mobile crane systems and is designed to enhance these powerful machines’ vertical reach and lifting efficiency. This hydraulic cylinder plays a crucial role in adjusting the angle of the crane’s boom, allowing operators to extend or retract the boom smoothly and precisely.

The mobile crane luffing cylinder is vital for enhancing the vertical reach, lifting efficiency, and overall performance of mobile cranes. With its robust construction, precise angle adjustment, extended vertical space, and improved lifting capacity, this hydraulic cylinder empowers operators to navigate challenging construction sites and industrial environments with ease and safety. By following the recommended usage methods and maintenance practices, operators can maximize the longevity and performance of the mobile crane luffing cylinder, contributing to increased productivity, efficiency, and operator confidence in completing various lifting tasks. Invest in this essential hydraulic component to elevate the capabilities of your mobile crane, ensuring successful and efficient operations in diverse construction and industrial applications.

Mobile Crane Luffing Cylinder Key Characteristics:

- 坚固的结构

- The mobile crane luffing cylinder is built with high-quality materials, ensuring durability, strength, and resistance to heavy loads and harsh environmental conditions.

- It is designed to withstand the rigors of demanding construction sites and maintain optimal performance over extended periods.

- Precise Angle Adjustment:

- This hydraulic cylinder enables precise angle adjustment of the crane’s boom, providing operators with fine control over vertical reach and positioning.

- It offers smooth and responsive movement, allowing for accurate load placement and minimizing the risk of collisions or accidents.

- Extended Vertical Reach:

- The mobile crane luffing cylinder extends the crane’s vertical reach by adjusting the angle of the boom.

- It enhances the crane’s flexibility in accessing elevated work areas, such as high-rise construction sites or industrial installations.

- Lifting Efficiency:

- By optimizing the angle of the boom, the luffing cylinder enhances the lifting efficiency of the mobile crane.

- It allows for better load distribution, reducing stress on the crane’s components and improving overall lifting capacity.

Mobile Crane Luffing Cylinder Parameter:

| Product Name | Mobile Crane Luffing Cylinder |

| Features: | Realizing the up-and-down pitching rotation of the boom is the main driving force for lifting |

| Bore diameter: | 100mm~560mm |

| Rod diameter: | 50mm~480mm Stroke≤5000 mm |

| Pressure: | Maximum 36MPa |

| Luffing Cylinder Applications: | Mobile Crane |

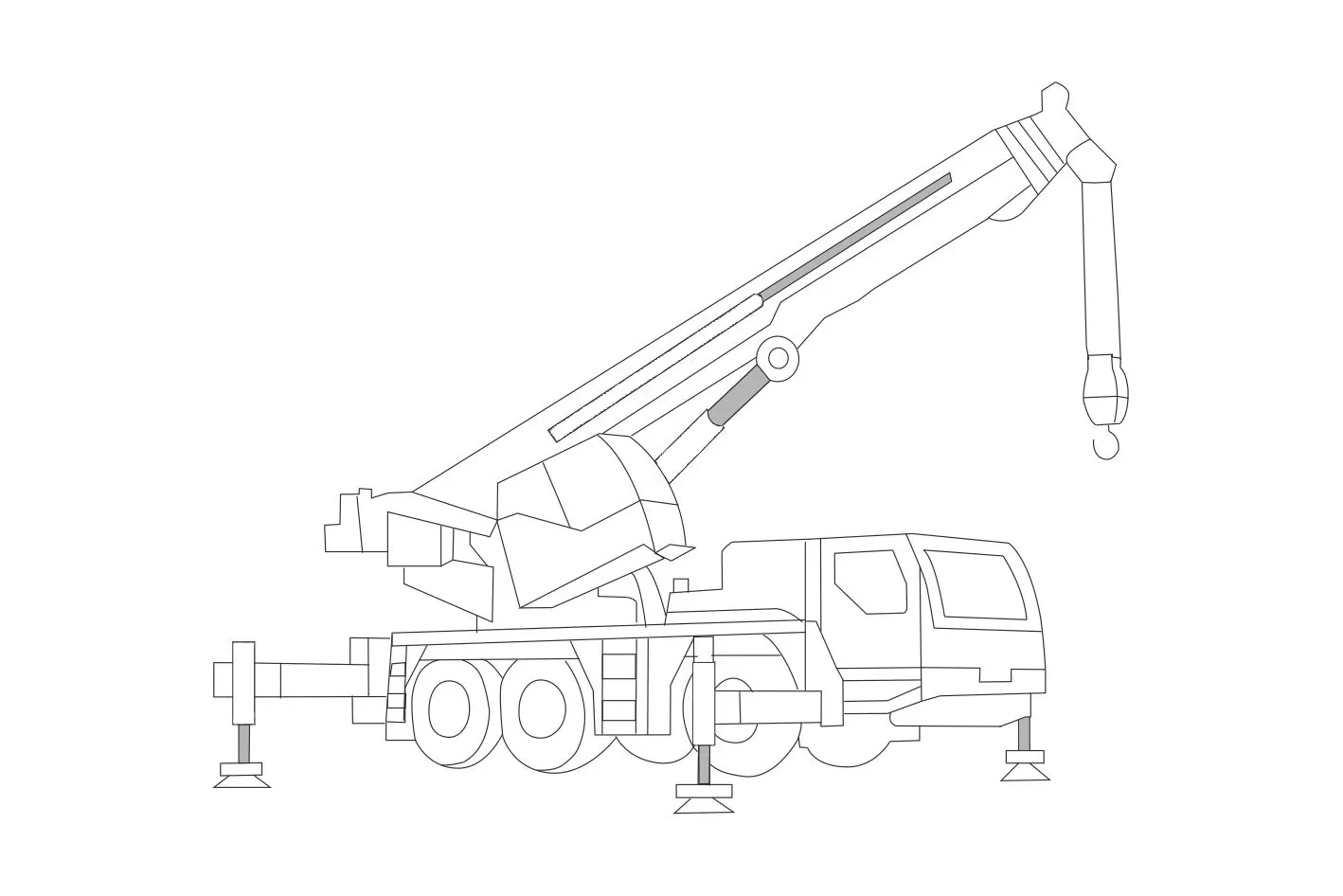

Mobile Crane Identification Diagram:

Usage Method Of Mobile Crane Luffing Cylinder:

- Safety Precautions:

- Before operating the mobile crane, ensure all safety guidelines and regulations are followed.

- Conduct a thorough inspection of the crane and its components, including the luffing cylinder, to ensure they are in proper working condition.

- Familiarize with Controls:

- Understand the control mechanisms and operating procedures specific to your mobile crane model.

- Identify the control for adjusting the luffing angle and ensure it functions properly.

- Luffing Angle Adjustment:

- Activate the control for the luffing cylinder, typically located in the operator’s cabin.

- Use the control to extend or retract the boom, adjusting the luffing angle as required for the lifting operation.

- Follow the load charts and manufacturer’s guidelines for the appropriate luffing angles based on the load weight and radius.

- Load Placement and Monitoring:

- Once the desired luffing angle is achieved, carefully position the load using the crane’s other controls, such as the hoist and swing mechanisms.

- Continuously monitor the load and adjust the luffing angle to maintain stability and safety during the lifting operation.

How To Release Pressure On Hydraulic System?

Releasing pressure from a hydraulic system is a necessary safety procedure that should be followed whenever maintenance or repair work is performed. Here are the general steps to release pressure from a hydraulic system:

- Identify the Power Source:

- Determine the power source supplying pressure to the hydraulic system, such as an electric motor, an engine-driven pump, or a manual pump.

- Locate the power switch or control valve associated with the power source.

- Shut Down the Power Source:

- Turn off the power switch or control valve to stop the power source from supplying pressure to the hydraulic system.

- If an engine powers the hydraulic system, shut off the engine completely.

- Engage the System Controls:

- Operate the control valves or switches on the hydraulic system to move actuators or components to neutral or resting positions.

- This step helps relieve residual pressure and allows the hydraulic fluid to flow back to the reservoir.

- Release Pressure at the Pump:

- If the hydraulic system has a pump with a pressure relief valve, locate the valve.

- Turn the pressure relief valve counterclockwise (or as specified by the manufacturer) to release pressure gradually.

- If available, check the system pressure gauge to ensure that pressure is relieved.

- Bleed Air from the System:

- Some hydraulic systems may have air trapped within the system, which can cause pressure buildup.

- To release air, open the air bleed valves or loosen fittings strategically to allow air to escape.

- Start from the lowest points in the system and work your way up to the highest points.

- Keep bleeding the system until a steady flow of hydraulic fluid is observed without air bubbles.

- Verify Pressure Release:

- Check the pressure gauge, if available, to ensure that the pressure has been fully released.

- Double-check the system controls to ensure that all actuators and components are neutral or resting.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: