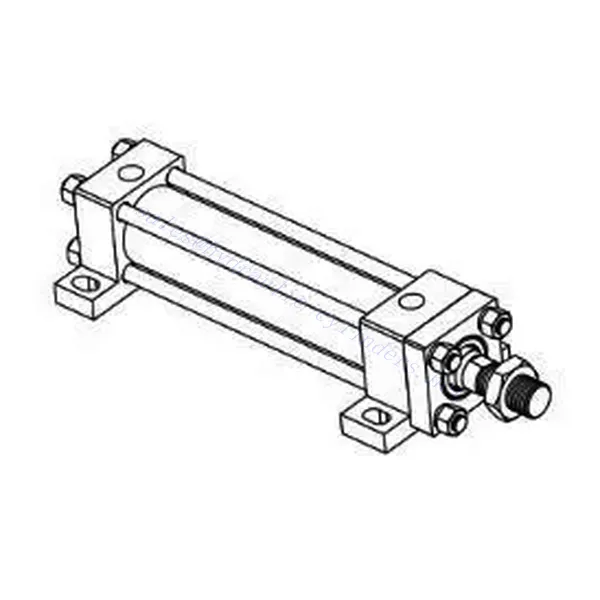

LA 左右脚踏式重型杆液压缸

LA 左右脚踏式重型杆液压缸

The LA left and right foot heavy rod hydraulic cylinder is a cutting-edge hydraulic element designed to meet the needs of various industrial applications. With its rugged construction, superior force output, and unique left and right foot design, this hydraulic cylinder offers exceptional power, precision, and versatility. Whether heavy lifting, pushing, or pulling, LA left and right foot type heavy-duty rod hydraulic cylinders provide reliable performance to optimize industrial operations.

重型杆式液压缸的基本特征:

坚固的结构 Using high-quality materials such as solid steel or alloys, LA left and right foot type heavy rod hydraulic cylinders ensure durability and longevity. Its rugged construction allows it to handle heavy loads, high pressures, and challenging environmental conditions, making it suitable for demanding industrial tasks.

High Force Output: This hydraulic cylinder boasts impressive force output, making it ideal for applications requiring substantial power. Its large piston diameter and high-pressure capabilities provide exceptional strength to handle heavy-duty tasks easily.

Left and Right Foot Design: The LA left and right foot heavy rod hydraulic cylinder has a unique left and right foot design that allows for various mounting options. This design is easy to install and integrate into multiple hydraulic systems and equipment configurations, providing flexibility and adaptability.

Precise Control: Equipped with precision machined components and high-quality seals, this hydraulic cylinder ensures accurate and reliable operation. It can precisely control the movement and positioning of loads for efficient and appropriate processing.

LA Left And Right Foot Type Heavy Rod Hydraulic Cylinder Parameter:

LA 左右脚踏式重型杆液压缸 Usage Method:

安装: Start by safely installing the LA left and right foot weight rod hydraulic cylinders using appropriate brackets or fixtures. Ensure proper alignment and stability during installation to prevent cylinder misalignment or stress.

液压系统集成: Connect hydraulic lines to cylinder ports per manufacturer’s instructions and guidelines. Integrate the cylinder into the hydraulic system by clicking on the appropriate pump or power unit. Ensure cylinder specifications and operating requirements are met.

控制和操作: The control valve in the hydraulic system regulates the flow of hydraulic oil into and out of the cylinder. Adjust the control Settings according to the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

LA 左右脚踏式重型杆液压缸 Maintenance:

Regular maintenance ensures optimal performance and longevity of the LA left and right foot type heavy rod hydraulic cylinder. Follow these maintenance guidelines:

定期检查: Perform routine inspections to identify signs of wear, damage, or leaks. Check for abnormalities in cylinder blocks, piston rods, seals, and other components. Resolve any issues promptly to prevent further injury or operational inefficiencies.

润滑: 给气缸的活动部件,包括拉杆和密封件,涂上建议的润滑油。定期润滑可最大限度地减少摩擦、降低磨损并确保平稳运行。根据制造商的润滑间隔指南使用适当类型的润滑油。

更换密封件: 如果发现密封件老化或泄漏,请使用制造商认可的原装部件更换密封件。损坏或磨损的密封件会影响油缸的性能并导致液压油泄漏。

清洁: 清洁气缸,清除灰尘、碎屑和其他污染物。在重新装配之前,使用非研磨性清洁剂,并确保所有部件都处于干燥状态。定期清洁可提高最佳性能,防止过早磨损或损坏。

How To Control Hydraulic Cylinder Speed?

Controlling the speed of a hydraulic cylinder is essential to ensure safe and efficient operation in various applications. There are several methods to control the speed of a hydraulic cylinder, including the following:

- Flow Control Valves: Flow control valves are commonly used to regulate the speed of hydraulic cylinders. These valves control the flow rate of hydraulic fluid entering or exiting the cylinder, thereby controlling the cylinder’s speed. There are two types of flow control valves:a. Throttle Valves: Throttle valves restrict the flow of hydraulic fluid by creating a narrow passage. They regulate the speed by controlling fluid flow through the valve. Throttle valves are often adjustable, allowing for precise speed control.b. Needle Valves: Needle valves have a tapered needle-like plunger that can be adjusted to restrict or allow fluid flow. By adjusting the position of the needle, the flow rate and, consequently, the cylinder speed can be controlled.

- Proportional Control Valves: Proportional control valves offer more precise control over the speed of hydraulic cylinders. These valves modulate the flow of hydraulic fluid based on electrical or electronic signals, allowing for fine adjustment of the cylinder’s speed. Proportional control valves are often used in applications where precise speed control is critical, such as in automation systems.

- Variable Displacement Pumps: In some hydraulic systems, variable displacement pumps control the speed of hydraulic cylinders. These pumps adjust the volume of fluid delivered to the cylinder, thereby regulating the cylinder speed. By changing the pump’s displacement or stroke volume, the speed of the cylinder can be adjusted accordingly.

- Load-Sensing Systems: Load-sensing systems are advanced hydraulic systems that adjust the pump’s output to match the load requirements. These systems monitor the pressure in the hydraulic circuit and adjust the pump’s displacement accordingly. By maintaining a constant pressure, load-sensing systems can regulate the cylinder speed even under varying load conditions.

- Accumulators: Hydraulic accumulators can be used to control the speed of hydraulic cylinders in specific applications. An accumulator stores hydraulic fluid under pressure, which can be released to supplement the flow from the pump. By controlling fluid release from the accumulator, the speed of the cylinder can be adjusted.

- Gearboxes or Transmission Systems: In some cases, mechanical gearboxes or transmission systems can be employed to indirectly control the speed of hydraulic cylinders. By adjusting the gear ratio or transmission settings, the rotational speed of the input shaft can be translated into the desired speed for the hydraulic cylinder.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

我们是最好的重型连杆液压缸制造商之一。我们可以提供广泛的重型连杆液压缸库存。我们还提供相应的 农用齿轮箱.我们的产品已出口到世界各地,并凭借卓越的产品质量和售后服务赢得了良好的声誉。我们热忱欢迎海内外客户与我们联系,洽谈业务,交流信息,共谋发展。 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: