HROB 型标准 B 型圆形液压缸

HROB 型标准 B 型圆形液压缸

The HROB standard Type B circular hydraulic cylinder is a versatile and reliable hydraulic element that provides efficient power and precise control in various industrial applications. Using advanced technology and high-quality standards, this hydraulic cylinder offers superior performance and durability. Whether in manufacturing, construction, or material handling, HROB standard b cylinders ensure smooth and efficient hydraulic operation.

HRO series round cylinder safe and stable, output, easy maintenance, beautiful appearance, high quality, suitable for all kinds of press.

HROA Type Circular Hydraulic Cylinder Characteristic Data:

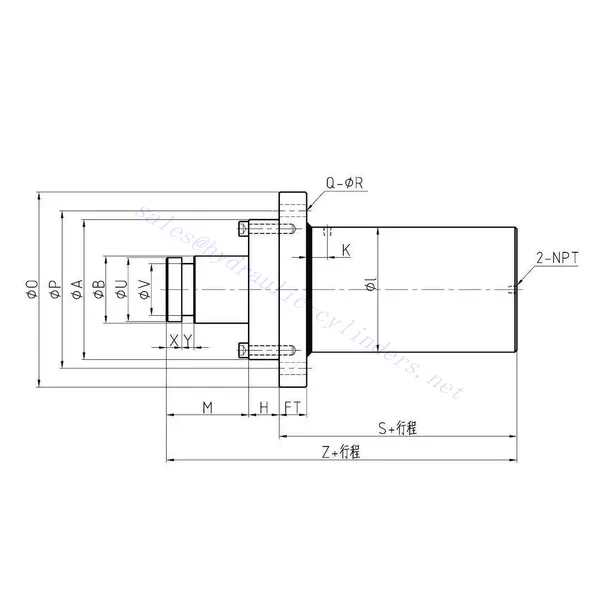

HROA Type Circular Hydraulic Cylinder Structure Diagram:

HROB Type Standard B Type Circular Hydraulic Cylinder Parameter: HROB 型标准 B 型圆形液压缸 External Tooth Type Specification Sheet:

HROB 型标准 B 型圆形液压缸 External Tooth Type Specification Sheet:

HROB 型标准 B 型圆形液压缸 Usage Method:

- Mounting and Installation:

- Determine the appropriate installation location for the HROB type standard B cylinder based on your equipment or mechanical requirements.

- Ensure that the mounting surface is clean, flat, and able to withstand the weight and load of the cylinder.

- Connection to Hydraulic System:

- Connect the hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Ensure proper alignment and secure connections to prevent leaks and optimize performance.

- Operating the Cylinder:

- The starting hydraulic system applies pressure to initiate the movement of the HROB standard B cylinder.

- The hydraulic control system is used to precisely control the cylinder extension, retraction and positioning to achieve efficient operation.

HROB 型标准 B 型圆形液压缸 特点:

- 坚固的结构 HROB Type standard B cylinders are manufactured with high-quality materials to ensure durability and longevity in demanding industrial environments.

- Precision and Control: This hydraulic cylinder provides precise motion and positioning control, allowing for accurate and efficient operation.

- Versatile Applications: HROB standard Type B cylinders are suitable for manufacturing, construction, material handling and other industries.

- Efficient Power Transmission: The cylinders efficiently convert hydraulic energy into mechanical force, providing reliable and consistent power output.

- Smooth Operation: The HROB standard Type B cylinder ensures smooth and reliable operation and minimizes vibration and noise during hydraulic movement.

How Hard Is It To Rebuild A Hydraulic Cylinder?

Rebuilding a hydraulic cylinder can be a complex task that requires mechanical knowledge, experience, and the right tools. The difficulty level involved in the process can vary depending on the specific design and condition of the cylinder. Here are some factors to consider:

- Expertise and Experience:

Rebuilding a hydraulic cylinder requires a good understanding of its components, functionality, and assembly. The process may be more manageable if you have experience working with hydraulic systems or have previously rebuilt hydraulic cylinders. However, if you’re new to hydraulic systems, seeking professional assistance or guidance is recommended. - Cylinder Design:

The complexity of rebuilding a hydraulic cylinder can depend on its design. Some cylinders have more straightforward construction with fewer internal components, making them relatively easier to rebuild. However, more advanced techniques, such as those with multiple stages or integrated features, can be more intricate and challenging to disassemble, reseal, and reassemble correctly. - Condition of the Cylinder:

The overall condition of the hydraulic cylinder also affects the rebuilding process. If the cylinder has severe damage, extensive wear, or corrosion, it may require additional repairs or part replacements, which can add complexity to the rebuild. Assessing the cylinder’s condition beforehand will help determine the level of work needed. - Tools and Equipment:

Rebuilding a hydraulic cylinder often requires specialized tools and equipment. These include hydraulic presses, seal installation tools, snap ring pliers and torque wrenches. Having the necessary tools and knowing how to use them properly is crucial for a successful rebuild. - Seal Replacement and Assembly:

One of the critical steps in rebuilding a hydraulic cylinder is replacing the seals. Ensuring the correct selection and installation of seals is critical for proper functioning and preventing leaks. It requires precision and attention to detail. Additionally, reassembling the cylinder components in the correct order and alignment is crucial for its optimal performance. - Testing and Verification:

After rebuilding the hydraulic cylinder, it’s essential to perform thorough testing to ensure it operates as intended. This can involve pressure testing, checking for leaks, and verifying the cylinder’s range of motion and performance. Proper testing helps identify issues and ensures the cylinder is safe and reliable.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: