头部矩形法兰式冶金液压缸

头部矩形法兰式冶金液压缸

The rectangular flange type metallurgical hydraulic cylinder is a state-of-the-art element specially designed for metallurgical applications. With its innovative design, superior performance, and rugged construction, this hydraulic cylinder ensures precise control, reliable operation, and exceptional durability in demanding industrial environments. Whether used in steel mills, foundries, or other metallurgical processes, head rectangular flange-type cylinders provide efficiency and productivity.

The hydraulic cylinder of Y-HG1 series metallurgical equipment is a double-acting piston cylinder; the cylinder diameter is generally within the range of 40~320mm, and the working pressure is <=16MPA. The hydraulic oil system can transport the active medium, such as emulsion, and install different models, such as flanges, earrings, pins, and release devices (base).

High precision CNC honing machine, automatic welding machine, vertical, horizontal machining center, gantry machining center, CNC lathe, and other processing equipment, product quality is stable and guaranteed.

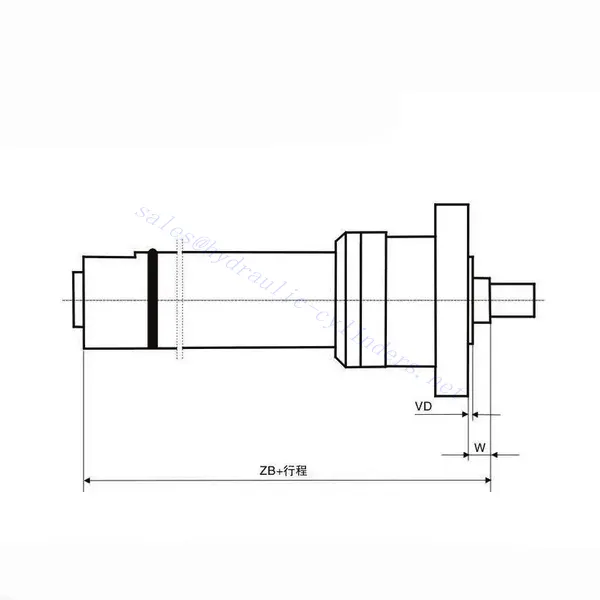

Head Rectangular Flange Type Metallurgical Hydraulic Cylinder Parameter:

头部矩形法兰式冶金液压缸 Usage Method:

- Mounting and Installation:

- Identify the appropriate mounting location for the metallurgical hydraulic cylinder based on the specific requirements of the metallurgical equipment.

- Ensure that the mounting surface is clean, flat, and capable of supporting the weight and load of the cylinder.

- Connection to Hydraulic System:

- Connect the metallurgical hydraulic cylinder to the hydraulic system using compatible hydraulic hoses or pipes.

- Ensure proper alignment and secure connections to prevent leaks.

- System Integration and Calibration:

- Integrate the metallurgical hydraulic cylinder into the metallurgical equipment or system following the manufacturer’s guidelines.

- Calibrate the system to achieve optimal performance and desired operation parameters.

- Operating the Cylinder:

- Activate the hydraulic system to apply pressure and initiate the movement of the hydraulic cylinder.

- Utilize the hydraulic control system to control the cylinder’s extension, retraction, and precise positioning for efficient metallurgical operations.

特点 Of Head Rectangular Flange Type Metallurgical Hydraulic Cylinder:

- Head Rectangular Flange Design: The unique rectangular flange design provides enhanced stability, precise alignment, and improved load distribution during operation, ensuring optimal performance in metallurgical processes.

- Metallurgical Application Focus: This metallurgical hydraulic cylinder is precisely engineered to meet the demanding requirements of metallurgical applications, offering reliability and durability in extreme conditions.

- Superior Performance: The cylinder delivers exceptional performance, enabling accurate positioning, smooth operation, and efficient productivity in metallurgical processes.

- 坚固的结构 Constructed from high-quality materials and designed to withstand heavy loads and harsh operating conditions, this metallurgical hydraulic cylinder ensures long-term durability and reliable performance.

- Safety Features: The design incorporates overload protection and emergency stop mechanisms, prioritizing operator safety during metallurgical processes.

如何找到液压缸的密封套件?

Finding the correct seal kit for a hydraulic cylinder is crucial to ensure proper fit, functionality, and performance. Here are some steps to help you find the appropriate seal kit:

- Identify the Cylinder Manufacturer and Model:

- Determine the manufacturer of the hydraulic cylinder. This information is often stamped or engraved on the cylinder body.

- If possible, note down the model number or any other identifying markings on the cylinder.

- Gather Cylinder Specifications:

- Measure the dimensions of the cylinder, including the bore diameter, rod diameter, and stroke length.

- Note any specific features or configurations unique to the cylinder, such as flanges, ports, or mounting styles.

- Research the Manufacturer’s Resources:

- Visit the manufacturer’s website or contact customer support to inquire about available seal kits for your specific cylinder model.

- Provide the manufacturer with the cylinder specifications and any identifying information you have gathered.

- Explore Online Hydraulic Seal Suppliers:

- Search for reputable online hydraulic seal suppliers or distributors.

- Utilize search filters or navigation menus on their websites to narrow down the selection based on cylinder specifications or manufacturer.

- Utilize Seal Kit Cross-Reference Tools:

- Some seal kit suppliers offer cross-reference tools or databases that help match cylinder models with compatible seal kits.

- Enter the cylinder manufacturer, model, or other specifications into the cross-reference tool to find suitable seal kits.

- Consult Hydraulic System Maintenance Manuals:

- Check if the equipment or machinery that uses the hydraulic cylinder has a maintenance manual.

- The manual may include information on recommended seal kits or part numbers.

- Seek Assistance from Hydraulic Experts:

- Reach out to hydraulic system specialists, maintenance professionals, or engineers with expertise in hydraulic systems.

- They can guide and recommend finding the correct seal kit for your hydraulic cylinder.

- Consider Custom Seal Kits:

- If you cannot find a seal kit specifically designed for your cylinder model, consider contacting a manufacturer or supplier that offers custom seal kits.

- Please provide them with accurate measurements and cylinder specifications to have a seal kit tailored to your requirements.

- Purchase and Install the Seal Kit:

- Once you have identified the appropriate seal kit, place an order with the supplier or manufacturer.

- Follow the installation instructions with the seal kit carefully to ensure proper installation and optimal performance.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: