HCYY11112008 Upper Leveling Cylinder For Aerial Work Vehicles

HCYY11112008 Upper Leveling Cylinder For Aerial Work Vehicles

The HCYY11112008 Upper Leveling Cylinder is a vital component for aerial work vehicles, providing essential stability and precision during elevated operations. Engineered to boost operational efficiency, this cylinder supports effective leveling and maneuvering, making it indispensable for construction, maintenance, and a variety of aerial tasks.

With its robust design and precision engineering, the HCYY11112008 is an essential asset for any aerial work vehicle. Its user-friendly features ensure reliability, making it a preferred choice among professionals. By integrating this cylinder into your workflow, you significantly enhance safety and operational efficiency, allowing your team to concentrate on their core tasks.

Invest in the HCYY11112008 and elevate your aerial work capabilities, ensuring your operations reach new heights of success.

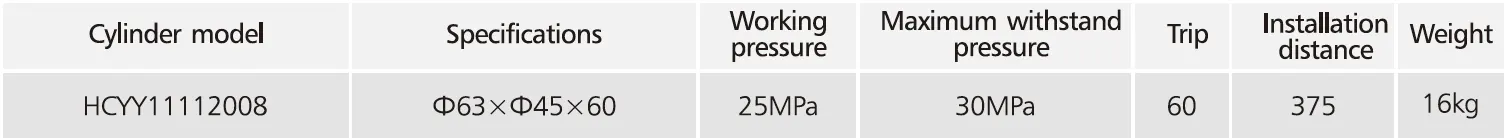

HCYY11112008 Upper Leveling Cylinder For Aerial Work Vehicles Parameter:

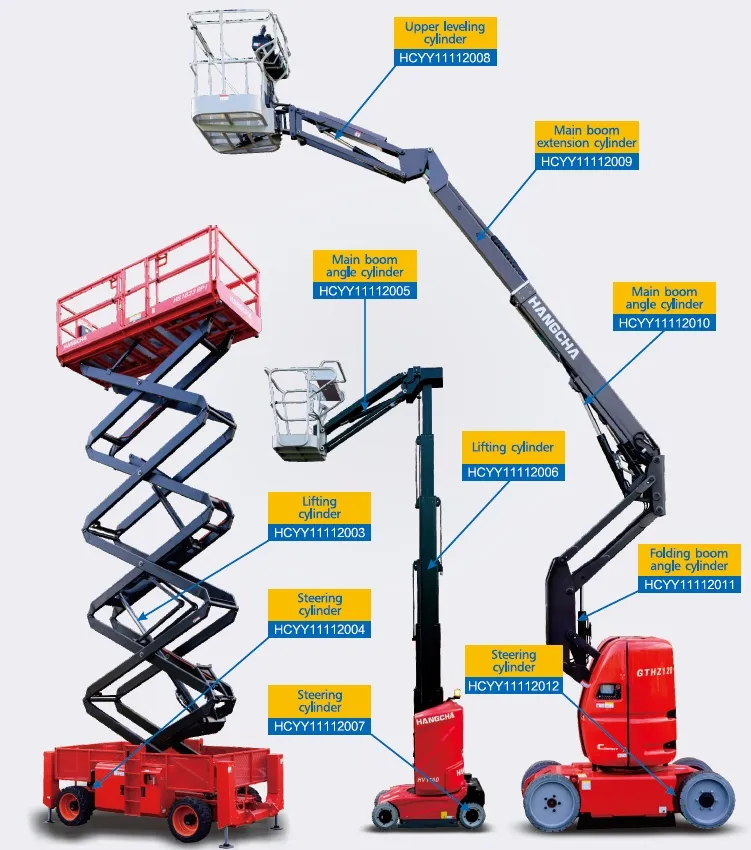

Cylinder Series For Aerial Work Vehicles:

Key Features of HCYY11112009 Main Boom Extension Cylinder For Aerial Work Vehicles:

坚固的结构

The HCYY11112008 Upper Leveling Cylinder is built from high-strength, corrosion-resistant materials that ensure it can withstand even the most challenging environmental conditions. This durability translates to long-lasting performance, significantly reducing the need for frequent replacements. Whether exposed to extreme temperatures, moisture, or abrasive elements, this cylinder maintains its integrity, making it a reliable choice for demanding aerial operations.

精密工程

Engineered with precision in mind, the HCYY11112008 allows for smooth and accurate leveling, which is critical for safe aerial operations. Its advanced design minimizes the risk of instability, ensuring that operators can confidently execute tasks at height. This level of accuracy not only enhances safety but also improves overall productivity, as workers can focus on their tasks without worrying about equipment malfunctions.

Easy Installation

The HCYY11112008 is designed for straightforward installation, which minimizes downtime and allows operators to quickly resume their work. Clear instructions and an intuitive design make it accessible for various skill levels, meaning that teams can efficiently integrate this component into their existing systems. This ease of installation helps streamline operations, allowing for more time spent on productive activities rather than on setup.

High Load Capacity

One of the standout features of the HCYY11112008 is its impressive load capacity. This cylinder can handle substantial weight, making it suitable for a wide range of aerial work applications. Whether lifting heavy equipment or supporting multiple workers, the HCYY11112008 ensures that safety is never compromised. Its robust performance instills confidence in operators, knowing they can rely on it for demanding tasks.

Versatile Compatibility

The HCYY11112008 Upper Leveling Cylinder boasts versatile compatibility with a variety of aerial work vehicles. This flexibility enhances functionality across different models, making it an ideal choice for fleet operations. Whether you’re operating a scissor lift, boom lift, or other aerial platforms, this cylinder integrates seamlessly, improving the overall efficiency of your machinery and expanding your operational capabilities.

How Does The HCYY11112008 Enhance Safety And Efficiency In Aerial Work Vehicles?

The HCYY11112008 Upper Leveling Cylinder enhances safety and efficiency in aerial work vehicles in several key ways:

Improved Stability

By providing precise leveling, the cylinder ensures that aerial work vehicles remain stable during operations at height. This stability reduces the risk of accidents caused by tipping or uneven surfaces.

Enhanced Load Management

With its high load capacity, the HCYY11112008 efficiently manages substantial weights, allowing operators to safely lift heavy equipment and personnel without compromising safety.

Quick Installation and Downtime Reduction

The easy installation process minimizes downtime, enabling operators to get back to work quickly. Less downtime translates to increased productivity and more efficient use of resources.

Reliable Performance in Harsh Conditions

Constructed from robust, corrosion-resistant materials, the HCYY11112008 withstands challenging environmental conditions, ensuring consistent performance and reducing the likelihood of mechanical failures that could lead to safety hazards.

Versatile Compatibility

Its compatibility with various aerial work vehicle models enhances operational flexibility, allowing teams to adapt quickly to different tasks without the need for extensive equipment changes.

Overall, the HCYY11112008 not only improves the safety of aerial operations but also significantly boosts operational efficiency, allowing teams to perform their work with confidence and reliability.

Aerial Work Vehicles Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: