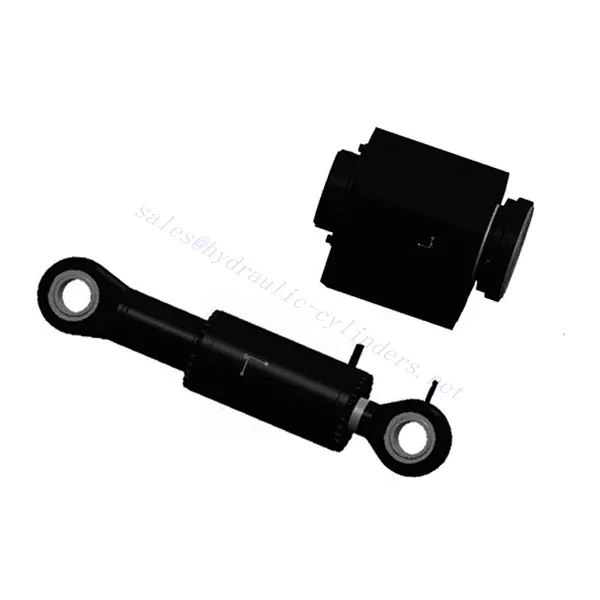

Double Shield TBM Torque Cylinder

Double Shield TBM Torque Cylinder

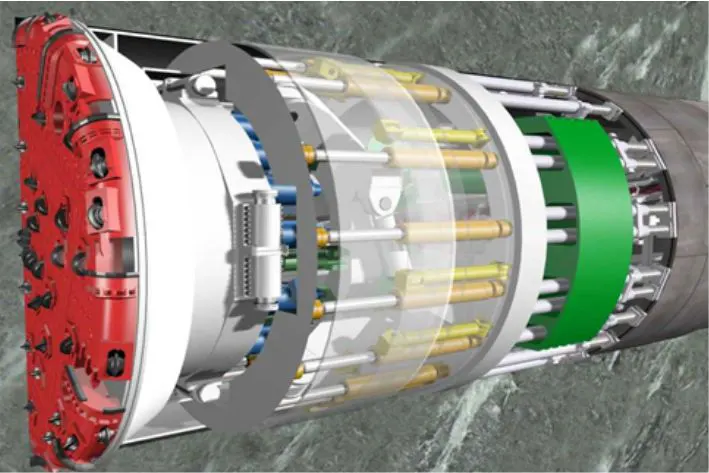

The double shield TBM torque cylinder is a cutting-edge hydraulic component that maximizes the efficiency and accuracy of tunnel boring machines. This specialized cylinder provides the necessary torque force for the rotation of the cutterhead, enabling smooth and precise excavation during tunneling operations. This comprehensive article will explore the key characteristics, usage methods, and maintenance guidelines for the double shield tbm torque cylinder.

The double shield TBM torque cylinder is a robust and reliable component revolutionizing tunnel boring operations. With its high torque output, precision engineering, rugged construction, and space-efficient design, this cylinder enhances the efficiency and accuracy of tunneling processes. By following the recommended usage methods and adhering to regular maintenance practices, the double shield tbm torque cylinder will continue to deliver exceptional performance, contributing to the success of tunneling projects. Embrace the power and precision of the double shield tbm torque cylinder, unleashing the full potential of tunnel dull with unparalleled efficiency and accuracy.

Double Shield TBM Torque Cylinder Key Characteristics:

- High Torque Output: The double TBM shield torque cylinder delivers a robust torque output, enabling efficient rotation of the cutterhead. Its powerful performance ensures effective and precise excavation, even in challenging geological conditions.

- Precision Engineering: This cylinder is engineered precisely to ensure smooth and accurate torque transmission. Its advanced design minimizes backlash and maintains consistent rotational speeds, resulting in precise excavation and improved tunneling productivity.

- Robust Construction: The double shield TBM torque cylinder features a sturdy construction built to withstand the demanding conditions encountered during tunnel boring. Its high-quality materials and meticulous craftsmanship ensure durability and reliability in the harshest environments.

- Compact and Space-Efficient: This cylinder optimizes space utilization within the tunnel boring machine with a compact design. Its streamlined construction allows for easy integration, minimizing interference with other components and maximizing the overall efficiency of the tunneling process.

Double Shield TBM Torque Cylinder Parameter:

| Product Name | Double Shield Tunnel Boring Machine Torque Cylinder |

| Features: | Transmit the torque of the cutter head |

| Specification: | Various structures and specifications of torque cylinders can be designed and produced according to customer requirements |

| Pressure: | up to 25MPa Special requirements up to 35MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield TBM Cylinder Application:

Usage Method Of Double Shield TBM Torque Cylinder:

- Cylinder Integration: Install the double shield tbm torque cylinder in the designated location within the tunnel boring machine, following the manufacturer’s guidelines and specifications. Ensure proper alignment and secure attachment to the TBM’s structure using suitable mounting brackets or accessories.

- 液压系统集成: Connect the cylinder to the TBM’s hydraulic system using compatible hoses and fittings. Verify that all connections are secure, leak-free, and adequately tightened to ensure optimal hydraulic performance.

- 控制和操作: Familiarize yourself with the TBM’s control system and the rules associated with the double shield tbm torque cylinder. Utilize these controls to activate, regulate, and monitor the torque output, adjusting it to match the excavation requirements and geological conditions.

- Monitoring and Adjustment: Continuously monitor the performance of the double shield tbm torque cylinder and the overall behavior of the tunnel boring machine. Adjust the torque output, considering ground conditions, cutter wear, and excavation progress to ensure optimal efficiency and productivity.

How To Change Hydraulic Cylinder Seals?

Changing hydraulic cylinder seals requires careful disassembly and reassembly of the cylinder components. Here is a step-by-step guide to help you through the process:

- Prepare the Cylinder:

- Disconnect the hydraulic cylinder from the system and ensure it is depressurized.

- Clean the exterior of the cylinder to prevent dirt or debris from entering during disassembly.

- Place the cylinder on a stable work surface and secure it using clamps or a vise.

- Identify the Seals:

- Determine the types and locations of the seals that need replacement.

- Hydraulic cylinders typically have multiple seals, including rod seals, piston seals, and wiper seals.

- Consult the manufacturer’s documentation or reference materials to identify the required seals.

- Disassembly:

- Remove any retaining components such as bolts, snap rings, or retaining rings that secure the cylinder head or cap.

- Carefully remove the cylinder head or cap, exposing the piston, rod, and seals.

- Pay attention to the arrangement and order of the seals for proper reassembly.

- Remove the Old Seals:

- Inspect the old seals for damage or wear and identify the appropriate removal method.

- Depending on the seal type, you may need to use seal removal tools, such as picks or hooks, or carefully pry them out using a flat-blade screwdriver.

- Take care not to damage the cylinder surfaces during seal removal.

- Clean and Inspect:

- Thoroughly clean the cylinder bore, rod, and surrounding components using a lint-free cloth or a suitable solvent.

- Inspect all components for any signs of damage, wear, or scoring. Replace any worn or damaged parts as necessary.

- Install the New Seals:

- Apply a thin layer of hydraulic fluid or seal lubricant to the new seals to aid in installation and ensure proper sealing.

- Carefully position the new seals in their grooves, ensuring they are correctly oriented.

- Use a seal installation tool or a soft mallet to gently press the seals into place, ensuring they are seated evenly and securely.

- Reassembly:

- Reinstall any remaining components removed during disassembly, such as bolts, snap rings, or retaining rings.

- Follow the manufacturer’s torque values and tightening sequence specifications to ensure proper sealing and alignment.

- Double-check the order and arrangement of the seals to ensure they are in the correct position.

- Testing and Verification:

- Reconnect the hydraulic cylinder to the system and ensure all connections are secure.

- Gradually restore system pressure, checking for any leaks or abnormal behavior.

- Cycle the hydraulic cylinder through its full range of motion to verify proper seal operation and overall functionality.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: