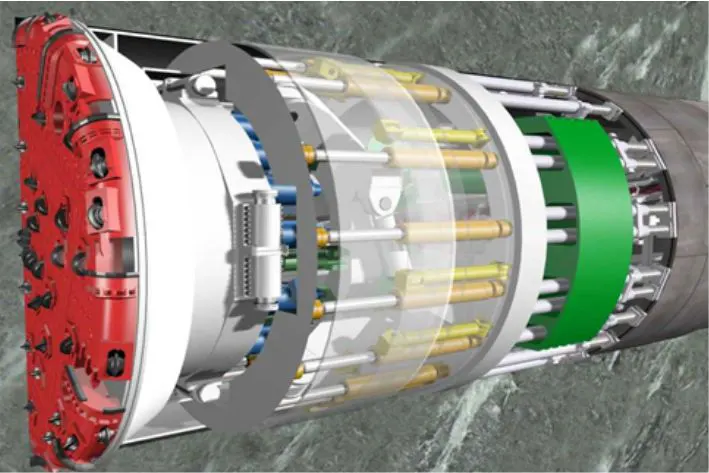

Double Shield TBM Main Thrust Cylinder

Double Shield TBM Main Thrust Cylinder

The double shield TBM main thrust cylinder is a cutting-edge hydraulic component designed to optimize the performance and efficiency of tunnel boring machines. This specialized cylinder is crucial in providing the necessary thrust force to propel the tunnel through a tedious process. This informative article will explore the key characteristics, usage methods, and maintenance guidelines for the double shield tbm main thrust cylinder.

The double shield TBM main thrust cylinder is a vital component that empowers tunnel boring machines to reach new levels of performance and efficiency. With its robust power, precision engineering, dual-acting design, and exceptional load-bearing capacity, this cylinder ensures the successful advancement of tunneling operations. By following the recommended usage methods and adhering to regular maintenance practices, the double shield tbm main thrust cylinder will continue to deliver outstanding performance, contributing to the success of tunneling projects. Experience the power and reliability of the double shield tbm main thrust cylinder, revolutionizing tunnel boring with unmatched performance and efficiency.

Double Shield TBM Main Thrust Cylinder Key Characteristics:

- Robust Power and Performance: The double shield TBM main thrust cylinder is engineered to deliver exceptional power and performance. With its high-pressure hydraulic system and precise control mechanisms, it generates the required thrust force to advance the tunneling process efficiently.

- Precision Engineering: This cylinder is meticulously crafted with precision engineering techniques, ensuring optimal alignment and performance. Its design incorporates high-quality materials and advanced manufacturing processes to withstand the demanding conditions encountered during tunnel boring operations.

- Dual-Acting Design: The double shield TBM main thrust cylinder features a dual-acting design, allowing it to exert force in both the extension and retraction directions. This capability enables versatile and controlled movement of the tbm, enhancing flexibility and adaptability during the tunneling process.

- Load-Bearing Capacity: The double shield TBM main thrust cylinder exhibits exceptional load-bearing capacity with its robust construction. It can withstand significant forces and pressures, ensuring stability and safety during tunneling.

Double Shield TBM Main Thrust Cylinder Parameter:

| Product Name | Double Shield Tunnel Boring Machine Main Thrust Cylinder |

| Features: | Provide the thrust of TBM forward tunneling |

| Bore diameter: | 220mm~380mm |

| Rod diameter: | 150mm~280mm Stroke: 1100mm~1700mm |

| Pressure: | up to 35MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield TBM Cylinder Application:

Usage Method Of Double Shield TBM Main Thrust Cylinder:

- Cylinder Installation: Install the double shield tbm main thrust cylinder according to the manufacturer’s guidelines and specifications. Ensure proper alignment and secure attachment to the TBM’s structure using suitable mounting brackets or accessories.

- Hydraulic System Integration: Connect the cylinder to the TBM’s hydraulic system using compatible hoses and fittings. Ensure all connections are secure, leak-free, and adequately tightened for optimal hydraulic performance.

- Control and Operation: Familiarize yourself with the TBM’s control system and the specific rules associated with the double shield TBM main thrust cylinder. Use these controls to activate and regulate the thrust force generated by the cylinder, adjusting it according to the required excavation speed and ground conditions.

- Monitoring and Adjustment: Continuously monitor the TBM’s performance and the behavior of the double shield TBM main thrust cylinder. Make necessary adjustments to the thrust force, considering the ground conditions, geological variations, and other factors affecting the tunneling process.

How To Build A Hydraulic Cylinder Bench?

Building a hydraulic cylinder bench requires a basic understanding of hydraulic systems, access to the necessary tools and materials, and adherence to safety protocols. Here’s a step-by-step guide on how to build a hydraulic cylinder bench:

- Gather the Required Materials and Tools:

- Steel or aluminum tubing for the bench frame

- Hydraulic cylinder mounting brackets

- Welding equipment (if welding is required)

- Hydraulic hoses and fittings

- Hydraulic pump and control valve

- Pressure gauge

- Wrenches, sockets, and other hand tools

- Safety equipment (gloves, goggles, etc.)

- Design and Plan:

- Determine the desired size and dimensions of the hydraulic cylinder bench based on the types of cylinders you intend to work on.

- Sketch out a design that includes the frame structure, mounting brackets, and space for the hydraulic pump and control components.

- Build the Frame:

- Cut the steel or aluminum tubing to the desired lengths for the bench frame.

- Weld or bolt the tubing together to create the frame structure according to your design.

- Ensure the frame is sturdy and stable, capable of supporting the weight of hydraulic cylinders during testing and maintenance.

- Mounting Brackets:

- Attach the hydraulic cylinder mounting brackets to the frame using welding or bolting methods.

- Ensure the brackets are securely fastened and properly aligned to accommodate different sizes and types of hydraulic cylinders.

- Hydraulic System Installation:

- Following the manufacturer’s instructions, install the hydraulic pump and control valve onto the bench frame.

- Connect the hydraulic hoses and fittings to the pump and control valve, ensuring proper sealing and tightness.

- Attach a pressure gauge to monitor the hydraulic pressure during cylinder testing and maintenance.

- Safety Measures:

- Ensure the hydraulic system is grounded correctly and that all electrical connections are secure.

- Place safety guards or shields around moving parts or potential pinch points to prevent accidents or injuries.

- Wear appropriate safety equipment, including gloves and goggles, when working with hydraulic systems.

- Test and Calibration:

- Before using the hydraulic cylinder bench, conduct a thorough check of all connections and fittings to ensure there are no leaks or loose components.

- Connect a hydraulic cylinder to the bench using the mounting brackets and hydraulic hoses.

- Operate the hydraulic pump and control valve to extend and retract the cylinder, checking for smooth and controlled movement.

- Use the pressure gauge to verify the accuracy of the hydraulic pressure.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: