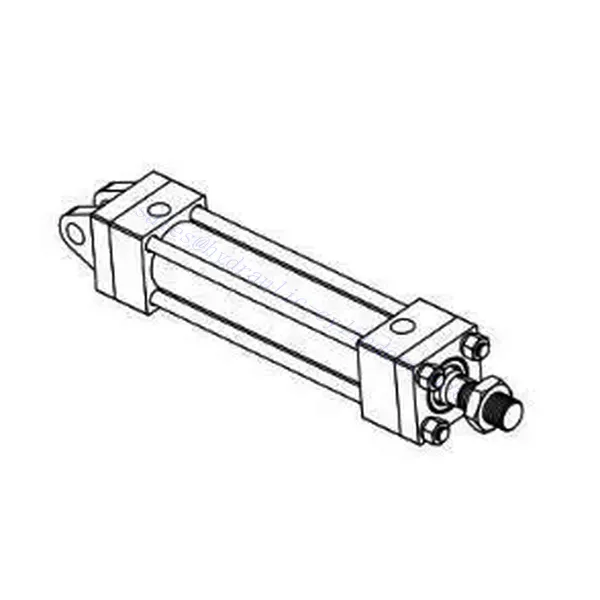

CB 型双耳式重杆液压缸

CB 型双耳式重杆液压缸

The Type CB binaural heavy rod hydraulic cylinder is a cutting-edge hydraulic element that delivers superior power, precision, and reliability in demanding industrial applications. With its innovative CB-type binaural design, robust construction, and advanced features, this hydraulic cylinder is designed to perform well in challenging conditions. Whether you need to lift, push, or pull heavy loads, the CB binaural type heavy rod hydraulic cylinder is your solution of choice for optimal performance and efficiency.

Essential Characteristics Of CB Type Binaural Type Heavy Rod Hydraulic Cylinder:

坚固的结构 The Type CB binaural type heavy rod hydraulic cylinder has a rugged construction that allows it to withstand extreme conditions and heavy workloads. Made of high-quality materials, it offers exceptional durability, longevity, and resistance to wear. The rugged design ensures reliable performance even in harsh operating environments.

CB Type Binaural Design: The CB type binaural design of the cylinder provides enhanced stability, controlled movement, and precise positioning. With two parallel rods extending from either side of the cylinder, it ensures balanced force distribution and minimizes deflection during operation. This design feature results in improved accuracy and efficiency.

Heavy Rod Capability: The cylinder’s CB type binaural design provides enhanced stability, controlled motion, and precise positioning. Two parallel rods extend from both sides of the cylinder, ensuring a balanced distribution of forces and minimizing deflection during operation. This design feature improves accuracy and efficiency.

CB Type Binaural Type Heavy Rod Hydraulic Cylinder Parameter:

CB Type Binaural Type Heavy Rod Hydraulic Cylinder Usage Method:

安装: First, safely install the two-axle heavy-rod hydraulic cylinder using appropriate mounting brackets or fixtures. Ensure proper alignment and stability during installation to prevent cylinder misalignment or excessive stress.

液压系统集成: Connect the hydraulic lines to the cylinder’s ports, following the manufacturer’s instructions and guidelines. Integrate the cylinder into the hydraulic system by connecting it to a suitable pump or power unit. Ensure compatibility with the cylinder’s specifications and operating requirements.

控制和操作: The control valve in the hydraulic system regulates the flow of hydraulic oil into and out of the cylinder. Adjust the control Settings according to the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

CB Type Binaural Type Heavy Rod Hydraulic Cylinder Maintenance:

Regular maintenance is essential to ensure optimal performance and longevity of the Biaxial Type Heavy Rod Hydraulic Cylinder. Follow these maintenance guidelines:

定期检查: Conduct routine inspections to identify signs of wear, damage, or leaks. Inspect the cylinder body, piston rod, seals, and other components for abnormalities. Address any issues promptly to prevent further injury or operational inefficiencies.

润滑: 给气缸的活动部件,包括拉杆和密封件,涂上建议的润滑油。定期润滑可最大限度地减少摩擦、降低磨损并确保平稳运行。根据制造商的润滑间隔指南使用适当类型的润滑油。

更换密封件: If you notice seal deterioration or leakage, replace the seals using genuine manufacturer-approved parts. Damaged or worn seals can compromise the cylinder’s performance and may lead to hydraulic fluid leaks.

清洁: Remove dirt, debris, and other contaminants and keep cylinders clean. Before reassembling, use a non-abrasive cleaner and make sure all parts are arid. Regular cleaning promotes optimal performance and prevents premature wear or damage.

How To Rebuild Hydraulic Cylinder Diagram?

Rebuilding a hydraulic cylinder involves disassembling the cylinder, inspecting its components, replacing worn or damaged parts, and reassembling the cylinder. While it is difficult to provide an interactive diagram, I can provide you with a step-by-step guide on how to rebuild a hydraulic cylinder:

- Gather Tools and Materials:

- Wrenches or socket set

- Hydraulic cylinder rebuild kit (includes seals, O-rings, and other necessary components)

- Cleaning solvent

- Lubricating oil or hydraulic fluid

- Soft mallet or hammer

- Bench vise (optional)

- Safety goggles and gloves

- Cylinder Disassembly:

a. Ensure the hydraulic system is depressurized and the cylinder is in a safe position.

b. Remove any mounting brackets or fixtures securing the cylinder to the equipment.

c. Locate and remove the retaining bolts or pins holding the cylinder’s end caps.

d. Gently tap the end cap with a soft mallet or hammer to dislodge it from the cylinder.

e. Once the end cap is removed, carefully pull out the piston assembly, taking note of its orientation and any seals that may come with it.

f. Repeat the process for the other end cap, if applicable. - Component Inspection:

a. Inspect the cylinder barrel for signs of scoring, pitting, or other damage. The cylinder barrel may need to be replaced if significant damage is present.

b. Examine the piston and rod for wear, scoring, or bent sections. If necessary, replace the piston or rod.

c. Check the seals and O-rings for wear, cracks, or damage. Replace any seals that show signs of deterioration. - 清洁:

a. Clean all disassembled components using a suitable cleaning solvent to remove dirt, debris, and old lubricant.

b. Use a soft cloth or brush to remove any stubborn residues.

c. Ensure all components are thoroughly dried before proceeding. - Reassembly:

a. Apply a small amount of lubricating oil or hydraulic fluid to the new seals and O-rings to ease installation.

b. Install the new seals and O-rings onto the piston and end caps, ensuring they are properly seated.

c. Carefully insert the piston assembly back into the cylinder barrel, aligning it with the rod and seals.

d. Securely attach the end caps to the cylinder barrel using the retaining bolts or pins.

e. Tighten the bolts or pins to the manufacturer’s specified torque settings.

f. Check the movement of the piston and rod to ensure smooth operation. - Cylinder Testing:

a. Reinstall the hydraulic cylinder onto the equipment, following the manufacturer’s guidelines.

b. Restore hydraulic pressure to the system and test the cylinder’s functionality.

c. Monitor for any leaks, abnormal noises, or irregular movements.

d. Make any necessary adjustments or repairs before returning the equipment to regular operation.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

我们是最好的重型连杆液压缸制造商之一。我们可以提供广泛的重型连杆液压缸库存。我们还提供相应的 农用齿轮箱.我们的产品已出口到世界各地,并凭借卓越的产品质量和售后服务赢得了良好的声誉。我们热忱欢迎海内外客户与我们联系,洽谈业务,交流信息,共谋发展。 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: