2.2KW Without Cooling Fan Standard Hydraulic Power Unit Pack

2.2KW Without Cooling Fan Standard Hydraulic Power Unit Pack

The 2.2KW without cooling fan standard hydraulic power unit package is a high-performance hydraulic power unit that provides reliable and efficient power for various industrial applications. With its strong power output, compact design, and no cooling fan, this power unit offers the best functionality and versatility for hydraulic systems requiring a compact and fanless solution. The 2.2KW standard hydraulic power unit package without a cooling fan ensures consistent power delivery and efficient operation, whether used for machine tools, material handling equipment, or other hydraulic power machinery.

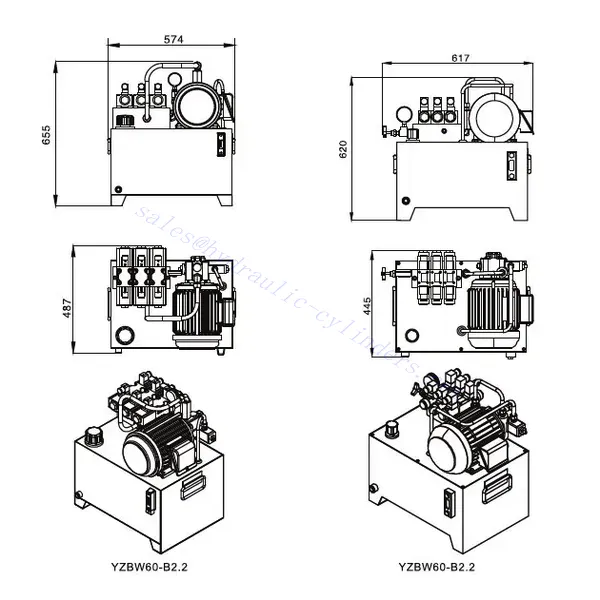

Standard Hydraulic Power Unit Packs Model Description:

2.2KW Without Cooling Fan Standard Hydraulic Power Unit Pack Parameter:

Standard Hydraulic Power Unit Packs Specification:

Standard Hydraulic Power Unit Packs Optional Parts:

Standard Hydraulic Power Unit Packs Schematic diagram:

Standard Hydraulic Power Unit Packs Key Characteristics and Benefits:

- Powerful Performance:

- The 2.2KW fan-less standard hydraulic power unit package features a robust 2.2KW rating, providing plenty of power for various hydraulic applications.

- Its high-performance motors ensure reliable and consistent power delivery, enabling the smooth operation of hydraulic machinery.

- Compact Design:

- This powerplant is designed with a compact form factor, making it ideal for installations with limited space or compact configurations.

- Its small footprint makes integrating into existing hydraulic systems easy without compromising performance or power output.

- Fanless Cooling System:

- 2.2KW No Cooling Fan The standard hydraulic power unit package is designed without cooling fans, eliminating the need for regular fan maintenance and reducing the risk of fan-related failures.

- The absence of cooling fans will also reduce noise levels and contribute to a quieter work environment.

- Standard Configuration:

- Equipped with standard hydraulic components such as motors, pumps, reservoirs, and control valves, this power unit offers compatibility with a wide range of hydraulic systems.

- The standard configuration simplifies installation and replacement, ensuring ease of use and compatibility with existing hydraulic systems.

How To Remove Hydraulic Cylinder From Front End Loader?

Removing a hydraulic cylinder from a front-end loader requires careful preparation and execution. Here’s a step-by-step guide to help you through the process:

- Safety First:

- Before starting work, ensure the front-end loader is parked on a level surface and the engine is turned off.

- Engage the parking brake and place wheel chocks behind the rear wheels to prevent accidental movement.

- Wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Identify the Cylinder:

- Locate the hydraulic cylinder you intend to remove. It will be connected to the loader’s hydraulic system and attached to specific mounting points.

- Relieve Hydraulic Pressure:

- To avoid sudden movements or potential injury, relieve the hydraulic pressure in the system before disconnecting the cylinder.

- Start the engine and operate the loader’s hydraulic controls to move the bucket or attachment to a fully extended or raised position.

- Shut off the engine and release any remaining pressure by operating the hydraulic controls a few times.

- Disconnect Hydraulic Connections:

- Locate the hydraulic hoses or lines connected to the cylinder. These are typically secured with fittings, bolts, or quick-release couplings.

- Carefully loosen and disconnect the hydraulic connections, using appropriate tools as needed.

- Be prepared for some hydraulic fluid to leak, so have a catch basin or absorbent material ready to minimize spills.

- Remove Mounting Hardware:

- Identify the mounting points where the cylinder is attached to the loader’s structure. These may include pins, bolts, or brackets.

- Remove any retaining pins or bolts securing the cylinder to the loader using the appropriate tools.

- Keep track of the hardware as you remove it, ensuring it isn’t misplaced or lost.

- Detach the Cylinder:

- With the hydraulic connections and mounting hardware removed, the cylinder should now be free to be detached.

- Carefully slide or maneuver the cylinder out of its mounting position, not damaging any surrounding components or hydraulic lines.

- Use lifting equipment or assistance to handle and remove the cylinder from the loader safely.

- Proper Storage and Maintenance:

- Once the cylinder is removed, inspect it for any signs of damage or wear. Replace any worn-out seals or components, if required.

- Store the hydraulic cylinder in a clean and dry area, protected from dust, moisture, and extreme temperatures.

- If the cylinder requires further servicing, consult the manufacturer’s guidelines or seek professional assistance.

工厂的能力和产能:

(1) 装配

我们拥有一流的自主研发装配平台。液压油缸生产车间拥有 4 条半自动提升油缸装配线和 1 条全自动倾斜油缸装配线,设计年生产能力 100 万支。特种油缸车间配备了各种规格的半自动清洗装配系统,设计年生产能力 20 万只,并配备了知名数控加工设备、加工中心、高精度油缸加工专用设备、机器人焊接机、自动清洗机、油缸自动装配机、自动喷漆生产线等。现有关键设备 300 多台(套)。设备资源的优化配置和高效利用,保证了产品的精度要求,满足了产品的高质量需求。

(2) 机加工

加工车间配备了定制的斜轨车削中心、加工中心、高速珩磨机、焊接机器人及其他相关设备,可加工最大内径 400 毫米、最大长度 6 米的气缸管。

(3) 焊接

(4) 油漆和涂料

配备中小型圆筒自动水性漆喷涂线,实现机器人自动上下料和自动喷涂,设计产能为每班 4000 件;

我们还拥有一条由动力链驱动的大型油缸半自动喷漆生产线,设计产能为每班 60 箱。

(5) 测试

我们拥有一流的检验设施和试验台,确保气缸的性能符合要求。

We are one of the best hydraulic power unit pack manufacturers. We can offer comprehensive hydraulic power unit pack stock. We also provide corresponding 农用齿轮箱. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and 与我们合作!

参观我们的 VR 工厂

通过以下方式参观我们的 VR 工厂

叉车液压缸如何工作?

液压缸应用: