Top Link Hydraulic Cylinder

Як один з виробників, постачальників та експортерів механічних виробів, ми пропонуємо гідравлічні циліндри та багато інших продуктів.

Будь ласка, зв'яжіться з нами для уточнення деталей.

Пошта:sales@hydraulic-cylinders.net

Виробник, постачальник, експортер гідравлічних циліндрів.

Top Link Hydraulic Cylinder

Our top link hydraulic cylinder for tractors is engineered for seamless integration with three-point hitch systems, providing precise control for agricultural implements. Designed to enhance efficiency, this hydraulic solution adjusts plows, seeders, and mowers accurately, making it ideal for plowing, no-till seeding, and grassland management.

It is built with high-strength materials and ensures durability in challenging farm environments, such as muddy or wet fields. Whether you’re optimizing seed placement in sustainable farming or managing pasture operations, our top link hydraulic cylinder delivers reliable performance to boost productivity across diverse agricultural applications.

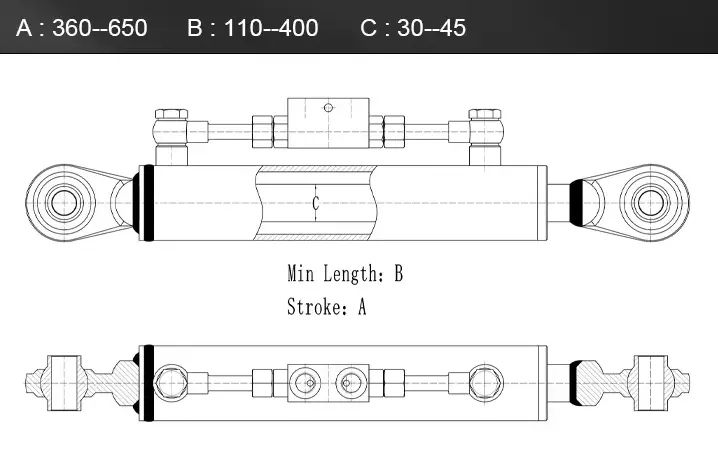

Top Link Hydraulic Cylinder Parameter:

Product Name | Top Link Cylinder |

Certification | ISO9001:2000 |

Bore Size | 2-6 inch |

Rod Size | 1.125-4 inch |

Stroke Size | 4-100 inch |

Pin Size | 0.5-2 inch |

Ports | G/SAE/NPT/M |

Top Link Hydraulic Cylinder Advantages:

Precise Depth and Angle Control: Top link hydraulic cylinders provide hydraulic precision for adjusting tractor implements like plows and seeders, ensuring consistent depth and angle. This accuracy enhances soil preparation and seed placement, leading to uniform crop growth and higher yields.

Robust and Durable Design: Built with high-strength steel and corrosion-resistant coatings, these cylinders are designed to withstand harsh agricultural environments, such as muddy fields, wet conditions, and abrasive soil, ensuring long-lasting reliability.

Flexible and Versatile Operation: Featuring double-acting functionality, top link hydraulic cylinders offer smooth push and pull movements, allowing farmers to adjust implements dynamically for tasks like plowing, no-till seeding, and grassland management with ease.

Compact and Space-Efficient: Engineered to integrate seamlessly into tractor three-point hitch systems, their compact design ensures easy installation and operation, even in tight spaces, without sacrificing performance or maneuverability.

Time and Labor Efficiency: By enabling quick and precise adjustments, top link hydraulic cylinders reduce the need for manual intervention, saving farmers time and effort during demanding tasks like field preparation, seeding, and hay harvesting.

Customizable Compatibility: Available in tailored designs, these cylinders can be customized to fit various tractor models and implements, ensuring perfect compatibility for diverse agricultural applications, from small farms to large-scale operations.

Top Link Hydraulic Cylinder Application:

Tractor Three-Point Hitch Adjustment:

Our top link hydraulic cylinders enable precise adjustments of tractor implements like plows and seeders, ensuring consistent depth and angle for efficient plowing and seeding, even in challenging field conditions like uneven terrain or rocky soil. This accuracy minimizes crop variability, enhances soil preparation, and ultimately boosts yields season after season.

No-Till Seeding Depth Control:

The top link hydraulic cylinder for no-till seeding delivers pinpoint depth regulation, minimizing soil disturbance while optimizing seed placement for crops like corn and soybeans. Perfect for sustainable farming, it helps retain soil moisture, reduces erosion, and promotes healthier root systems for better crop resilience and growth.

Grassland Management and Hay Harvesting:

Designed for mowers and balers, our top link hydraulic cylinders adjust cutting heights with precision, delivering uniform results in pasture operations and hay production across diverse landscapes. This ensures high-quality forage, reduces equipment strain, and saves valuable time during peak harvest periods.

Field Transport and Implement Positioning:

During field transport, our top link hydraulic cylinders for tractors lift implements to avoid obstacles like rocks or ditches, offering flexible positioning to enhance maneuverability and protect valuable equipment. This seamless control allows farmers to transition between tasks quickly, improving overall operational efficiency.

How Can A Top Link Hydraulic Cylinder Improve The Efficiency Of No-Till Seeding On Uneven Terrain?

A top link hydraulic cylinder for no-till seeding revolutionizes efficiency by delivering unmatched depth control for seeders, even on uneven terrain like steep slopes, rocky patches, or compacted soil. Imagine a soybean farmer in the Midwest facing a hilly field—our top link hydraulic cylinder ensures seeds are placed at a consistent 2-5 cm depth for crops like corn and soybeans, promoting uniform germination and robust root development. Its double-acting functionality allows seamless push and pull adjustments, adapting instantly to terrain changes without stopping to tweak settings manually.

This means less downtime during tight planting windows, saving hours in the field. By minimizing soil disturbance, the top link hydraulic cylinder for tractors also preserves soil structure, enhances moisture retention, and reduces erosion, fostering sustainable farming practices that lead to healthier crops and higher yields over time. Farmers can confidently tackle challenging landscapes, knowing their equipment is protected and their operations are streamlined for maximum productivity.

Hydraulic Cylinder Production Area:

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line with a designed annual production capacity of million pieces. The special cylinder workshop has semi-automatic cleaning and assembly systems of various specifications with a designed annual production capacity of 200000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high-precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

The machining shop is equipped with custom-made tilt guiderailturning centers, machining centers, high-speed honing machines, welding robots, and other relevant equipment, which can handle the machining work of cylinder tubes with 400mm Max ID and 6 meters of Max length.

We have a fully automatic water-based paint coating line for small and medium cylinders, which realizes automatic loading and unloading and automatic spraying robots with a designed production capacity of 4000 places per shift. We have another semi-automatic painting line for large-scale cylinders driven by a power chain, and the design capacity is 60 crates per shift.

To further improve product performance and establish the leadership position of our hydraulic cylinders in the industry, our company and zjimee jointly established a Comprehensive performance laboratory of hydraulic cylinders, hydraulic valves, and hydraulic pumps; the lab is computer-assisted testing using electro-hydraulic technology, the test conditions are preset by a computer which improves the test accuracy and system versatility, and the experimental data.

The automatic collection is realized through the application of sensors, and the output data, such as the internal leakage and load efficiency of the cylinder or the vale, are directly processed by the computer and converted to standard units (ml/min%). At the same time, to ensure the working safety of the hydraulic system, the state monitoring function is carried out for key performance parameters such as”oil temperature monitoring, liquid level monitoring, filter device monitoring,” etc. Among them, the hydraulic cylinder test stand can test the performance of the “load

efficiency “and” internal leakage” by readings. At the same time, it is equipped with a grating ruler measuring instrument that meets the requirements of all test items of hydraulic cylinder products according to the national standard.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: