Small Excavator Boom Cylinder

Як один з виробників, постачальників та експортерів механічних виробів, ми пропонуємо гідравлічні циліндри та багато інших продуктів.

Будь ласка, зв'яжіться з нами для уточнення деталей.

Пошта:sales@hydraulic-cylinders.net

Виробник, постачальник, експортер гідравлічних циліндрів.

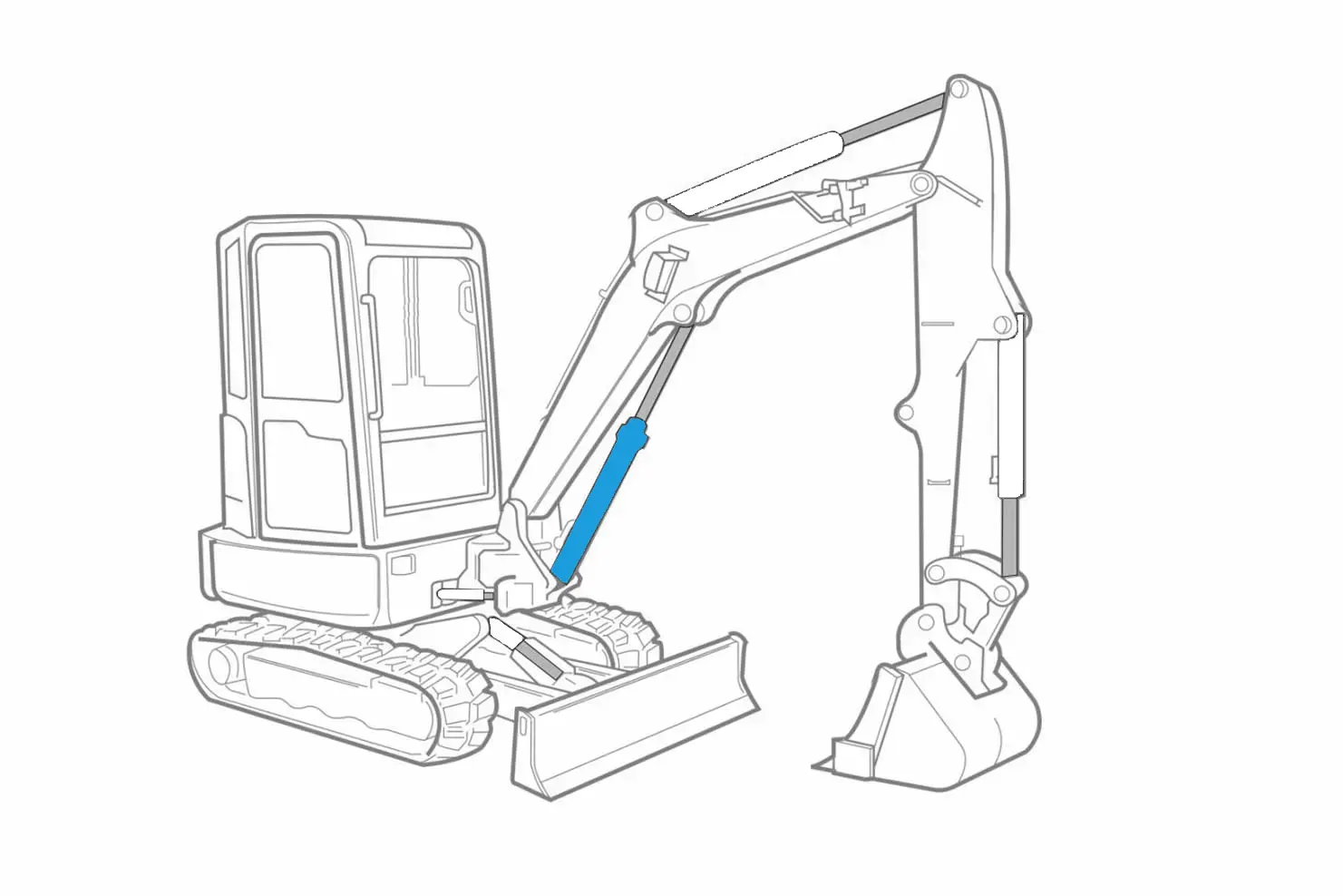

Small Excavator Boom Cylinder

The Small Excavator Boom Cylinder is a powerful hydraulic component that optimizes small excavators’ lifting and reaching capabilities. This cylinder is specifically engineered to deliver exceptional strength, durability, and precision in compact construction machinery.

The Small Excavator Boom Cylinder is a vital hydraulic component that enhances the efficiency and performance of small excavators. With its compact design, high lifting capacity, and precise control, this cylinder empowers operators to tackle various excavation tasks easily and precisely. By following the recommended usage methods and maintenance practices, operators can ensure optimal performance and longevity of the Small Excavator Boom Cylinder, resulting in increased productivity and successful completion of construction and excavation projects. Invest in this exceptional hydraulic cylinder to elevate the capabilities of your small excavator and achieve superior results in your lifting and reaching operations.

Small Excavator Boom Cylinder Key Characteristics:

- Compact Design and Robust Construction

- The Small Excavator Boom Cylinder is purpose-built for small excavators, ensuring a perfect fit and optimal performance.

- Its compact design and robust construction allow it to withstand rigorous operating conditions, providing long-lasting durability.

- High Lifting Capacity and Reach

- Despite its small size, the cylinder delivers impressive lifting capacity and reach, enabling efficient material handling and excavation tasks.

- It provides the necessary power and extension to maneuver in confined spaces and access hard-to-reach areas.

- Precise Control and Smooth Operation

- The cylinder’s advanced hydraulic system ensures precise control and smooth operation, allowing operators to perform tasks with accuracy and efficiency.

- It offers excellent responsiveness and maneuverability, facilitating precise positioning and enhanced productivity on the job site.

- Reliable Performance and Safety

- Built with high-quality materials and stringent manufacturing standards, the Small Excavator Boom Cylinder delivers reliable performance in demanding environments.

- It incorporates safety features that prevent sudden drops or unexpected movements, ensuring operator and equipment safety during operation.

Small Excavator Boom Cylinder Parameter:

| Product Name | Small Excavator Boom Cylinder |

| Features: | Control the lifting motion of the big arm |

| Bore diameter: | 50mm~125mm |

| Rod diameter: | 25mm~75mm Stroke≤1000mm |

| Thrust force: | Maximum 361KN |

| Bore diameter: | 125mm/pressure29.4MPa |

Small Excavator Boom Cylinder Identification Diagram:

Usage Method Of Small Excavator Boom Cylinder:

- Installation and Integration

- Consult the manufacturer’s instructions for proper installation of the Small Excavator Boom Cylinder.

- Ensure compatibility and secure attachment to the excavator’s boom assembly.

- Follow recommended torque specifications and use appropriate mounting hardware.

- Operational Considerations

- Familiarize yourself with the controls and operation of the excavator, including the boom cylinder.

- Practice operating the excavator and boom cylinder in a controlled environment before commencing actual work.

- Adhere to safety guidelines, operate within the excavator’s load, and reach limits to prevent accidents and equipment damage.

- Efficient Lifting and Reaching Techniques

- Utilize the Small Excavator Boom Cylinder’s precise control to optimize lifting and reaching techniques.

- Maintain a stable position while lifting or extending the boom, avoiding sudden or jerky movements that can strain the cylinder.

- Ensure proper positioning of the load and maintain balance for safe and efficient material handling.

How To Remove Hydraulic Cylinder From Excavator?

Removing a hydraulic cylinder from an excavator requires careful attention and adherence to proper procedures to ensure safety and prevent damage to the equipment. Here are general steps to guide you through the process:

- Preparation:

- Ensure the excavator is turned off and parked on a level surface.

- Engage the safety lock and secure the boom and arm in a stable position.

- Put on appropriate personal protective equipment, such as gloves and safety glasses.

- Identify the Cylinder:

- Locate the hydraulic cylinder you wish to remove. It may be attached to the boom, arm, or other excavator components.

- Relieve Hydraulic Pressure:

- Before disconnecting any hydraulic lines or fittings, it’s crucial to release the pressure in the system to prevent sudden movements or fluid spray.

- Start by locating your excavator model’s pressure relief valve or pressure release procedure.

- Follow the manufacturer’s guidelines to depressurize the hydraulic system properly.

- Disconnect Hydraulic Lines:

- Identify the hydraulic lines connected to the cylinder. These lines carry hydraulic fluid to and from the cylinder.

- Use appropriate wrenches or fittings to loosen and disconnect the hydraulic lines from the cylinder.

- Place a container or absorbent material beneath the disconnected lines to catch residual hydraulic fluid.

- Remove Mounting Hardware:

- Locate the mounting points of the cylinder. These may be bolts or pins securing the cylinder to the excavator’s structure.

- Use the appropriate tools to remove the mounting hardware depending on the specific design.

- Ensure proper support for the cylinder during removal to prevent it from falling or causing damage.

- Detach the Cylinder:

- Carefully slide or maneuver the cylinder out of its mounting position. If it’s tightly fitted, you may need to gently tap it with a rubber mallet or use a hydraulic cylinder puller for assistance.

- Ensure that no other components or structures are obstructing the cylinder’s removal.

- Inspection and Maintenance:

- Once the cylinder is removed, inspect it for any signs of damage, leaks, or wear.

- Clean the cylinder and inspect the rod, seals, and other components for any signs of corrosion, scoring, or excessive wear.

- Perform any necessary maintenance or repairs before reinstalling the cylinder.

- Reinstallation or Replacement:

- To reinstall the hydraulic cylinder, follow the reverse steps of the removal process, ensuring proper alignment and torque specifications.

- If the cylinder is being replaced, carefully install the new cylinder according to the manufacturer’s instructions and guidelines.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: