Mining Dump Truck Front Suspension Cylinder Hydraulics On Trucks

Як один з виробників, постачальників та експортерів механічних виробів, ми пропонуємо гідравлічні циліндри та багато інших продуктів.

Будь ласка, зв'яжіться з нами для уточнення деталей.

Пошта:sales@hydraulic-cylinders.net

Виробник, постачальник, експортер гідравлічних циліндрів.

Mining Dump Truck Front Suspension Cylinder Hydraulics On Trucks

The mining dump truck front suspension cylinder hydraulics on trucks is a critical component that significantly enhances stability and performance in demanding mining operations. Specifically engineered for mining dump trucks, this hydraulic system plays an essential role in maintaining the integrity of the suspension, effectively absorbing shocks, and ensuring a smooth ride even on the toughest terrains.

These hydraulics not only boost ride comfort but also optimize overall truck performance. With their robust construction and excellent shock absorption capabilities, they offer adjustable suspension settings and reliable load distribution. This ensures that mining operations run smoothly and efficiently.

To maximize the longevity and reliability of the mining dump truck front suspension cylinder hydraulics, it’s crucial for operators to adhere to recommended usage methods and maintenance practices. By investing in this high-performance hydraulic component, you can significantly improve stability, productivity, and operator comfort, making your mining operations safer and more efficient. Choose these advanced hydraulics to elevate your mining dump truck performance to new heights!

Mining Dump Truck Front Suspension Cylinder Parameter:

| Product Name | Mining Dump Truck Front Suspension Cylinder Hydraulics On Trucks |

| Features: | Support weight, absorb, and eliminate vibration |

| Bore diameter: | 150mm~450mm |

| Rod diameter: | 120mm~400mm Stroke≤400mm |

| Thrust force: | Maximum38MPa |

| Front Suspension Cylinder Applications: | Mining Dump Truck |

Mining Dump Truck Front Suspension Cylinder Hydraulics On Trucks Key Characteristics:

Robust Construction

The mining dump truck front suspension cylinder hydraulics on trucks are built with high-strength materials specifically designed to endure the extreme conditions of mining applications. Their sturdy construction guarantees exceptional durability and longevity, even in harsh environments characterized by heavy loads and constant vibrations.

Optimal Shock Absorption

These hydraulics are engineered to effectively absorb shocks and vibrations encountered during off-road mining operations. This minimizes the impact on the truck’s chassis, enhancing stability and providing a comfortable ride for both the driver and the payload.

Adjustable Suspension

With adjustable suspension settings, the mining dump truck front suspension cylinder hydraulics allow operators to tailor the truck’s ride height to meet specific mining conditions. This flexibility ensures optimal ground clearance, improved maneuverability, and reduced strain on the truck’s components, enhancing overall performance.

Reliable Load Distribution

The mining dump truck front suspension cylinder hydraulics play a crucial role in evenly distributing the load across the truck’s axles. This functionality helps maintain balance and stability, preventing excessive weight transfer during dumping, and ensuring safe operation in all scenarios.

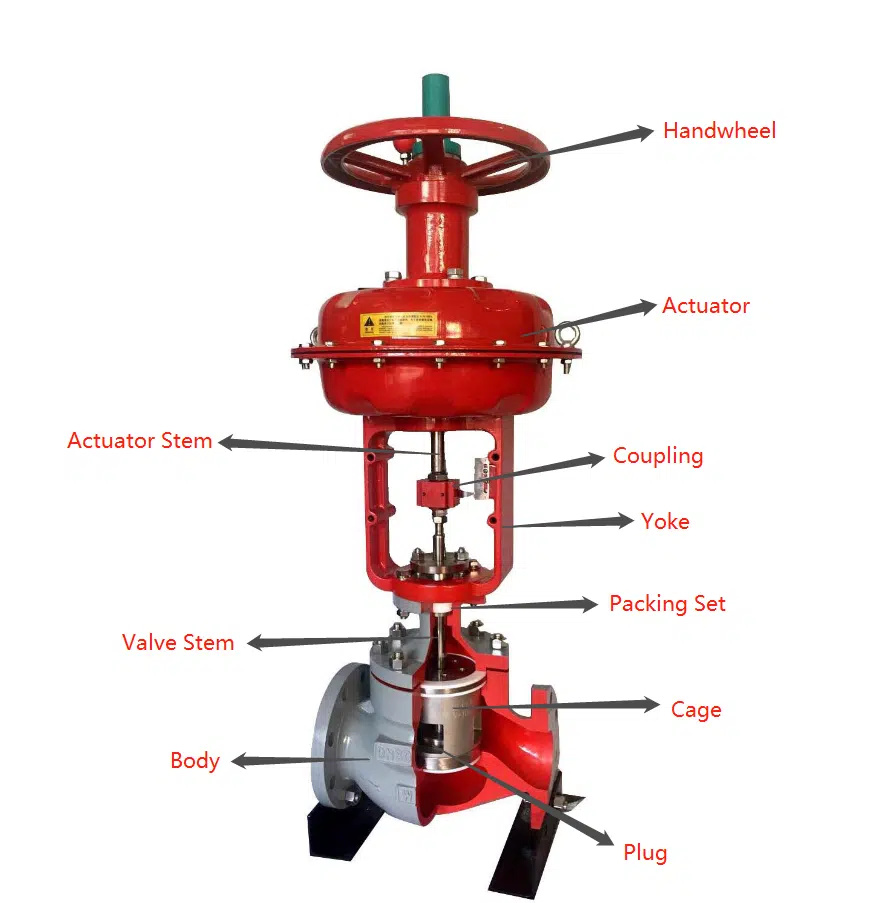

Mining Dump Truck Front Suspension Cylinder Hydraulics On Trucks Identification Diagram:

How To Install Hydraulics On A Truck?

1. Gather Your Materials and Tools

Hydraulic Components:

Pump: Often considered the heart of your hydraulic system, the pump generates the necessary pressure to circulate hydraulic fluid. Its efficiency directly impacts the performance of the entire system, making regular inspections crucial for ensuring reliable operation.

Cylinder: This component is responsible for converting hydraulic energy into mechanical force. By applying pressure, the cylinder moves various parts of the system, enabling precise control over the truck’s functions. Understanding the cylinder’s capabilities can help optimize performance in challenging mining environments.

Hoses and Fittings: These are essential for fluid transfer and creating secure connections throughout the hydraulic system. High-quality hoses and fittings are vital for preventing leaks and ensuring the efficient flow of hydraulic fluid. Regular checks can help identify wear and tear, preventing potential failures.

Reservoir: The reservoir serves as the storage unit for hydraulic fluid, maintaining an adequate supply for the system. Properly maintaining fluid levels is essential for optimal performance. A well-designed reservoir also helps dissipate heat and filter contaminants, further enhancing the longevity of your hydraulics.

Tools You’ll Need:

Wrenches: Essential for tightening connections and ensuring all fittings are secure. Using the right size wrench prevents damage to the bolts and maintains the integrity of the system.

Screwdrivers: Necessary for securing components and making adjustments. A variety of screwdriver types (flathead and Phillips) can help ensure that all parts are properly fastened for optimal performance.

Drill: Useful for creating additional mounting holes if needed. A drill allows for precise placements, enabling you to customize installations to fit your specific requirements.

Saw: Ideal for making adjustments or modifications to components. Whether you need to shorten a part or create a new fit, a saw provides the versatility to adapt to your operational needs.

Hydraulic Fluid: Often referred to as the lifeblood of your hydraulic system, this fluid is crucial for efficient operation. Regularly checking and maintaining the correct fluid levels ensures smooth functioning and prolongs the life of your hydraulic components.

2. Plan the Installation

Choose Locations Wisely: Identify and mark ideal mounting spots for the pump, reservoir, and cylinder, ensuring easy access and optimal functionality.

Review Schematics: Study the system layout and connection diagrams specific to your truck to avoid any confusion during installation.

3. Install the Hydraulic Pump

Mount the Pump Securely: Fasten the pump to the truck frame or engine using appropriate brackets, ensuring it’s stable and secure.

Align with PTO: If applicable, connect the pump to the power take-off (PTO) for seamless power transfer from the engine.

4. Install the Hydraulic Reservoir

Position Strategically: Place the reservoir near the pump for easy access during maintenance and fluid checks.

Secure It Well: Use sturdy brackets or bolts to firmly attach the reservoir to the truck frame, preventing movement during operation.

5. Install the Hydraulic Cylinder

Mount the Cylinder: Secure the hydraulic cylinder in your desired location, such as the dump bed or other operational areas.

Ensure Stability: Check that it’s tightly attached to the frame or bed to handle the stresses of operation without shifting.

6. Run Hydraulic Hoses

Connecting Hoses

Connect Hoses: Begin by carefully attaching hoses from the pump to both the cylinder and the reservoir. It’s crucial to route the hoses away from moving parts and heat sources to prevent wear and potential failure. Proper routing not only enhances safety but also ensures optimal fluid flow, contributing to the overall efficiency of your mining dump truck front suspension cylinder hydraulics.

Use Proper Fittings

Use Proper Fittings: After connecting the hoses, double-check all fittings to ensure they are tight and leak-free. Utilize thread sealant where necessary to enhance the integrity of the connections. This step is critical in preventing leaks, which can lead to system inefficiencies or even damage. Regular inspections and maintenance of these fittings will keep your hydraulic system operating smoothly and reliably.

7. Connect Control Valves

Install Control Valves Conveniently: Position control valves in the cab or near the driver’s seat for easy access while driving.

Connect to Hydraulic Lines: Attach the valves to the hoses leading to the cylinder, ensuring clear and unobstructed pathways for fluid flow.

8. Fill the Hydraulic System

Add Hydraulic Fluid: Carefully fill the reservoir with the appropriate hydraulic fluid, following manufacturer specifications.

Check for Leaks: Thoroughly inspect all connections and fittings for any signs of leakage, tightening as needed.

9. Test the System

Operate the Controls: Engage the hydraulic system to test its functionality, ensuring smooth operation without any hitches.

Monitor Performance: Watch for leaks and listen for unusual sounds during operation. Make adjustments as necessary for optimal performance.

10. Final Adjustments

Secure All Components: Go through each component to ensure everything is tightly fastened and secure.

Make Necessary Adjustments: Fine-tune any parts for improved performance, ensuring your hydraulic system is ready for action.

What Does An Accumulator Do In A Hydraulic System?

In a hydraulic system, an accumulator serves as an essential component that helps regulate and optimize system performance. It stores hydraulic energy in the form of pressurized fluid, which can be released when needed. The primary functions of an accumulator in a hydraulic system are as follows:

- Energy Storage:

An accumulator stores pressurized hydraulic fluid, functioning as a reservoir of energy within the system. It accumulates energy during periods of low demand and releases it during peak demand or when there is a sudden need for additional power. This energy storage capability helps improve the system’s overall efficiency and responsiveness. - Pressure Stabilization:

Accumulators help stabilize pressure fluctuations within the hydraulic system. As the fluid is compressed within the accumulator, it acts as a buffer, absorbing pressure spikes and surges. By maintaining a more consistent pressure, the accumulator ensures smoother system operation and helps protect sensitive components from potential damage caused by pressure variations. - Volume Compensation:

In hydraulic systems where there are variations in fluid volume due to temperature changes or component movement, accumulators play a vital role. They provide a means for compensating for these volume changes, preventing excessive pressure build-up or cavitation. By accommodating fluid volume fluctuations, accumulators help maintain system stability and protect against potential damage. - Emergency Power Source:

Accumulators can serve as an emergency power source in the event of a power failure or system shutdown. The stored hydraulic energy can be quickly released to actuate critical functions, such as safely stopping or retracting actuators, enabling controlled shutdown procedures, or maintaining essential system operations until power is restored or alternative measures are taken. - Pulsation Dampening:

In hydraulic systems where there are reciprocating or cyclically operating actuators, accumulators help dampen pulsations or pressure oscillations. By absorbing and smoothing out these pressure fluctuations, accumulators contribute to improved system performance, reduced noise, and extended component life. - Leakage Compensation:

Accumulators also compensate for minor fluid leaks within the hydraulic system. If there is a small loss of fluid due to leakage, the accumulator can supply additional fluid to maintain the desired pressure and system functionality. This compensatory capability helps ensure uninterrupted operation and prevents potential performance degradation caused by minor leaks.

How To Check Hydraulic Fluid On Dump Truck?

1. Safety First

Park the Dump Truck: Ensure the truck is parked on a flat, stable surface to prevent any unintended movement during maintenance. This step is crucial for your safety and the safety of those around you.

Engage the Parking Brake: Always engage the parking brake and turn off the engine before starting any maintenance procedures. This prevents accidental movement and ensures the truck is secure.

2. Locate the Hydraulic Reservoir

Identify the hydraulic fluid reservoir, which is typically marked and conveniently located near the hydraulic system components. Familiarizing yourself with its location helps streamline maintenance and enhances efficiency during inspections.

3. Inspect the Fluid Level

Using a Dipstick: If your reservoir has a dipstick, carefully remove it, wipe it clean with a lint-free cloth, and reinsert it to accurately check the fluid level. This method ensures you get a precise reading, vital for the system’s performance.

Using a Sight Glass: If equipped with a sight glass, simply observe the fluid level directly. This provides a quick and easy way to gauge whether the fluid is at the appropriate level without any additional tools.

4. Check Fluid Condition

Examine the hydraulic fluid’s color and clarity. It should be a clean, bright color. If the fluid appears dark, murky, or contains particles, it indicates contamination. In such cases, replacing the fluid is essential to maintain the efficiency and longevity of the mining dump truck front suspension cylinder hydraulics.

5. Add Hydraulic Fluid if Necessary

If the fluid level is found to be low, add the manufacturer-recommended hydraulic fluid until it reaches the appropriate level. Using the correct type of fluid is critical, as it ensures optimal operation of the mining dump truck front suspension cylinder hydraulics and prevents potential damage to the system.

6. Check for Leaks

Conduct a thorough inspection of the area surrounding the reservoir and hoses for any signs of leaks or damage. Look for wet spots, puddles, or any discoloration that could indicate a hydraulic fluid leak. Early detection and repair of leaks are essential to avoid costly downtime and ensure safe operation.

7. Close the Reservoir

After adding fluid, ensure that the reservoir cap is securely replaced. A tight seal prevents contaminants from entering the system and maintains the necessary pressure, which is vital for the proper function of the hydraulics.

8. Test the System

Start the truck and briefly operate the hydraulic system to circulate the fluid throughout the system. This step allows you to ensure that all components are receiving adequate lubrication. After running the system, recheck the fluid level to confirm it remains within the recommended range, ensuring the mining dump truck front suspension cylinder hydraulics are operating at peak performance.

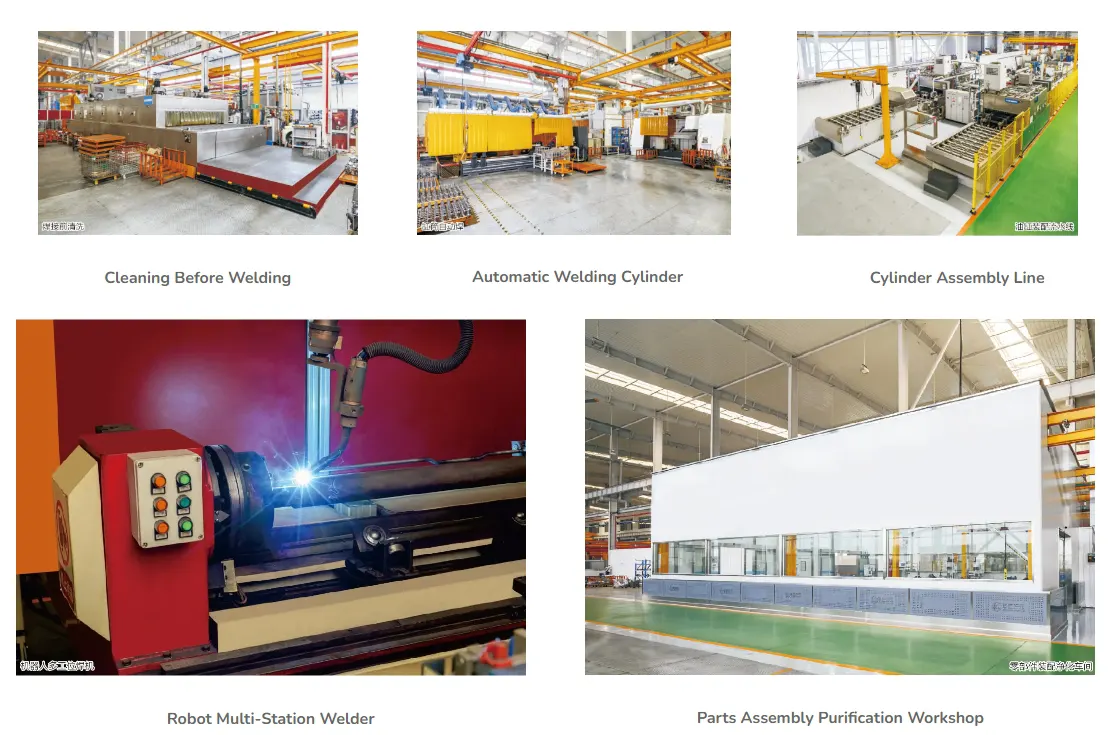

Capability & Capacity Of Factory:

(1) Assembly

Our facility boasts a top-tier independent research and development assembly platform dedicated to hydraulic cylinder production. We operate four semi-automatic lifting cylinder assembly lines and one fully automatic tilt cylinder assembly line, with an impressive annual production capacity of 1 million cylinders.

In our specialized cylinder workshop, we utilize a semi-automatic cleaning assembly system designed for various specifications, capable of producing 200,000 cylinders annually. Our workshop is equipped with advanced CNC machining equipment, a machining center, high-precision cylinder processing tools, robot welding machines, automatic cleaning systems, and an automated cylinder assembly line. Additionally, we have a fully automated painting production line.

With over 300 pieces of critical equipment, our optimal resource allocation ensures that we meet the strict accuracy and quality standards required by our clients. This commitment to efficiency and precision positions us as a leader in the hydraulic cylinder industry.

(2) Machining

Our machining shop features state-of-the-art equipment, including a customized inclined rail turning center, a precision machining center, a high-speed honing machine, and advanced welding robots. This sophisticated setup enables us to efficiently process cylinder tubes with a maximum inner diameter of 400mm and a length of up to 6 meters.

With our cutting-edge technology, we ensure high-quality machining that meets the diverse needs of hydraulic cylinder production.

(3) Welding

(4) Painting & Coating

Our facility features advanced automatic water-based paint coating lines specifically designed for small and medium-sized cylinders. These lines utilize robotic technology for efficient loading, unloading, and spraying, achieving a remarkable production capacity of 4,000 pieces per shift.

In addition, we operate a semi-automatic paint production line for large cylinders, powered by a robust power chain, with a designed capacity of 60 cases per shift. This combination of automation and efficiency ensures high-quality finishes for all our hydraulic cylinders.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are a renowned manufacturer of гідроциліндри, recognized as one of the best in the industry. Our extensive product line includes a wide range of hydraulic cylinders tailored to meet various applications. In addition to hydraulic cylinders, we also provide high-quality agricultural gearboxes, ensuring our customers have access to comprehensive solutions for their machinery needs.

With a commitment to excellence, we have successfully exported our products to clients worldwide, earning a strong reputation for superior product quality and exceptional after-sales service. Our dedication to customer satisfaction has positioned us as a trusted partner in both domestic and international markets.

Why Choose Us?

Professional Expertise: Our team comprises industry professionals with extensive knowledge and experience in hydraulic systems, ensuring that we deliver top-notch products and services.

International Certifications: We adhere to strict quality standards and hold various international certifications, demonstrating our commitment to delivering reliable and safe hydraulic solutions.

Custom Solutions: We understand that each customer’s needs are unique. That’s why we offer customized hydraulic cylinders and gearboxes tailored to meet specific requirements.

Advanced Production Equipment: Our state-of-the-art manufacturing facilities utilize the latest technology and equipment, enabling us to produce high-quality products efficiently.

Comprehensive After-Sales Support: Our commitment to our customers extends beyond the sale. We provide ongoing support and maintenance services to ensure optimal performance of our products.

We invite customers from around the globe to reach out to us for business negotiations, information exchange, and collaboration opportunities. Together, we can achieve greater success in the hydraulic industry!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: