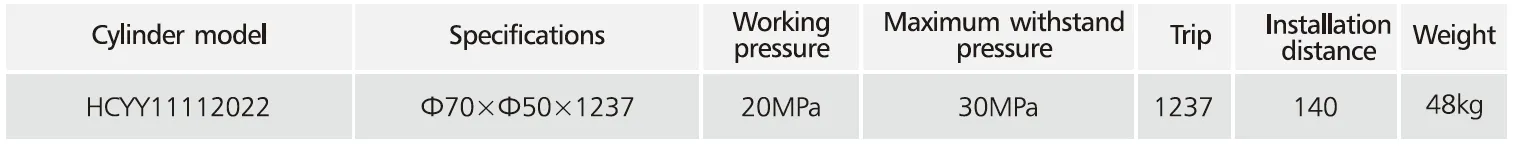

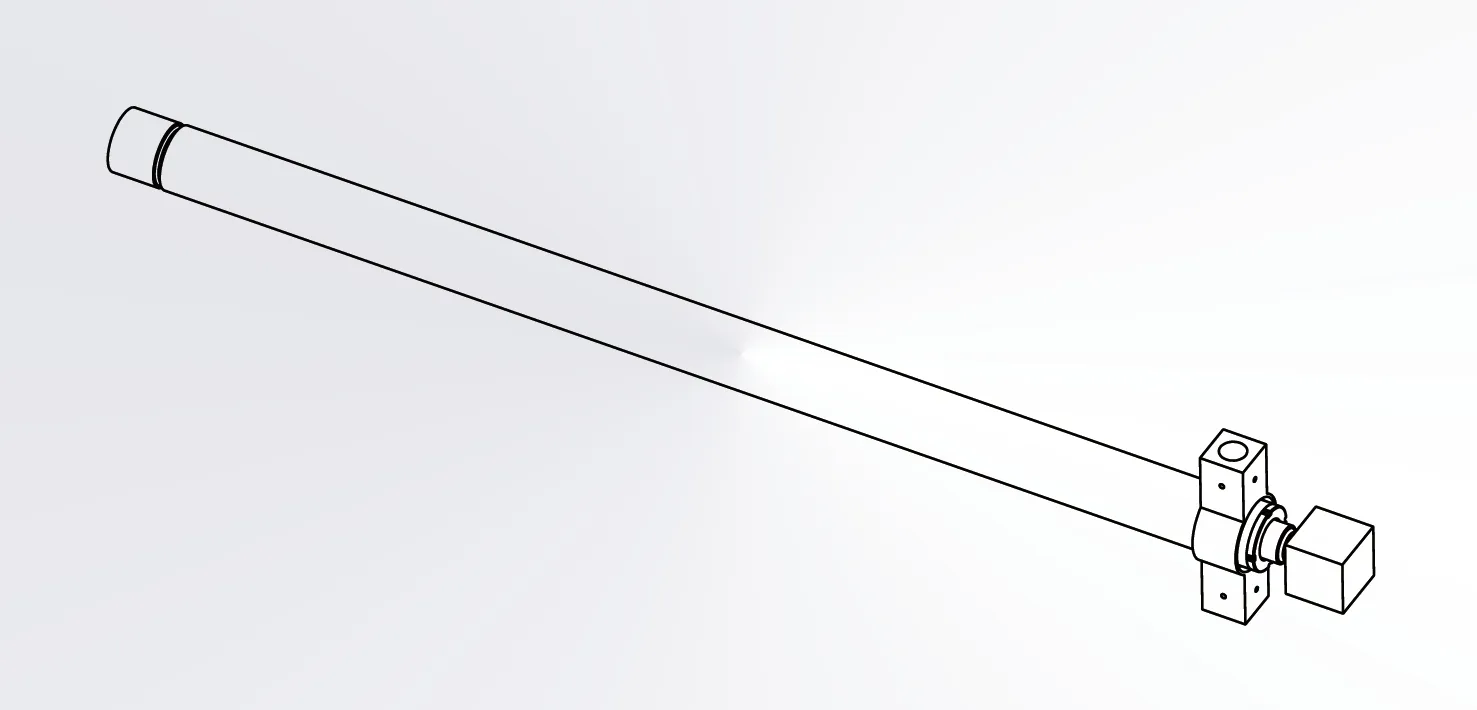

HCYY11112022 Cylinder For Opening Rack Support For Truck Cranes

Як один з виробників, постачальників та експортерів механічних виробів, ми пропонуємо гідравлічні циліндри та багато інших продуктів.

Будь ласка, зв'яжіться з нами для уточнення деталей.

Пошта:sales@hydraulic-cylinders.net

Виробник, постачальник, експортер гідравлічних циліндрів.

HCYY11112022 Cylinder For Opening Rack Support For Truck Cranes

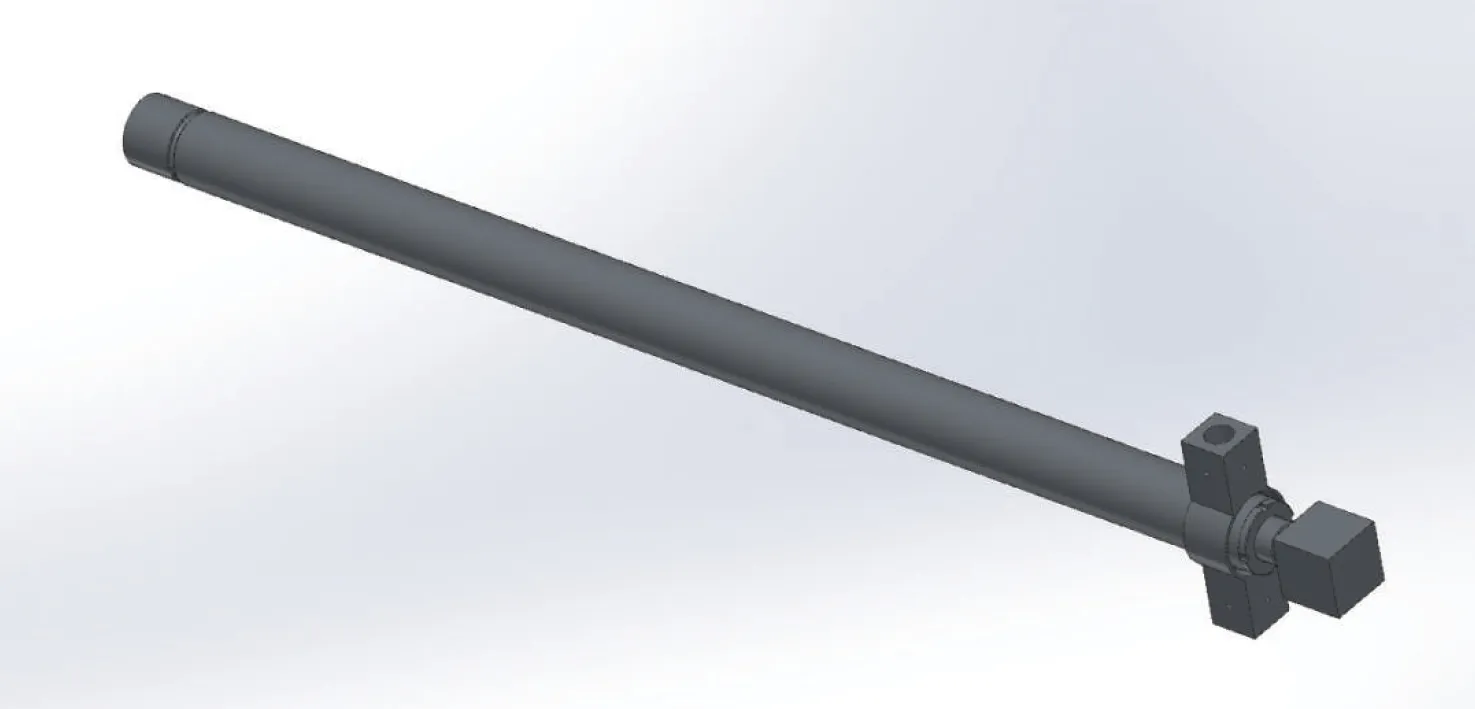

The HCYY11112022 Cylinder is a crucial component specifically engineered for truck cranes, significantly improving their operational efficiency and safety. This cylinder supports the opening rack mechanism, facilitating smooth and reliable movement of the crane’s structure during various lifting tasks.

Designed to enhance both lifting efficiency and safety, the HCYY11112022 Cylinder features robust construction and efficient performance. Its straightforward installation process allows operators to confidently manage a range of lifting tasks.

Regular maintenance and proper usage are essential for ensuring the HCYY11112022 remains a dependable asset in your crane operations. By investing in this cylinder, you enhance your crane’s capabilities, leading to increased productivity and safety on the job site. Elevate your operations with the HCYY11112022 Cylinder today.

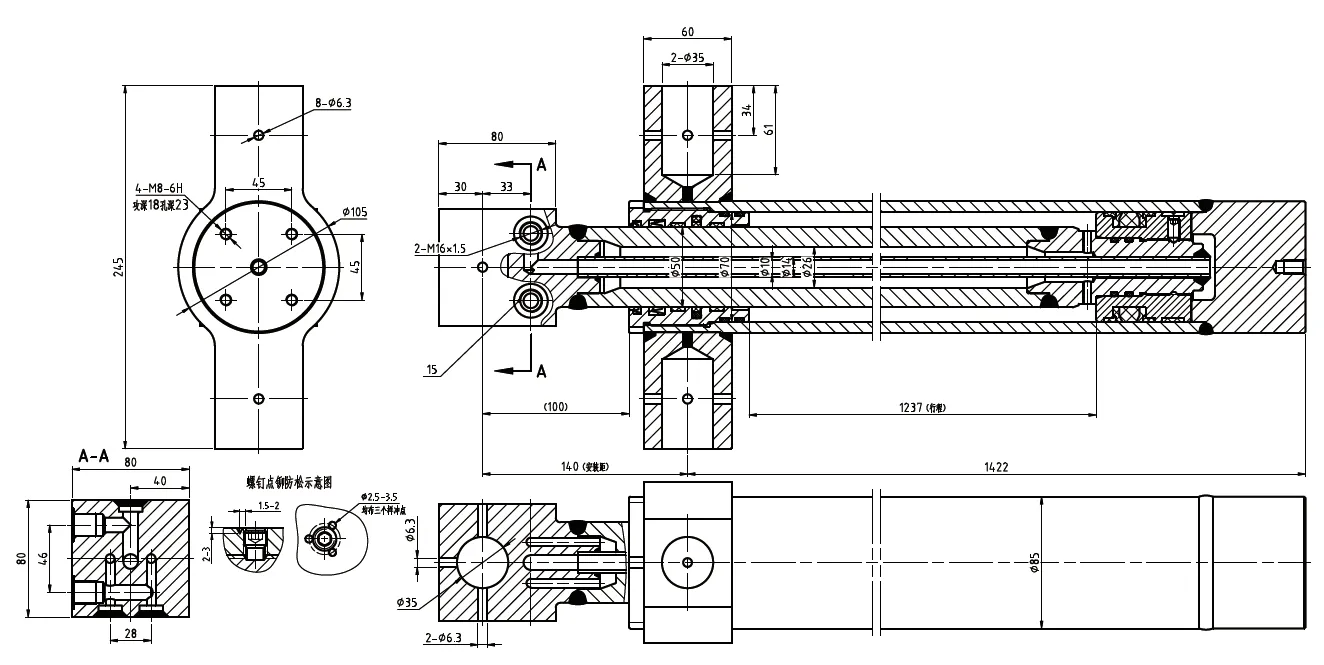

HCYY11112022 Cylinder For Opening Rack Support For Truck Cranes Parameter:

Cylinder Series For Truck Cranes:

Key Features of HCYY11112022 Cylinder For Opening Rack Support For Truck Cranes:

The HCYY11112022 Cylinder is an indispensable component specifically engineered for truck cranes, delivering significant enhancements in operational efficiency and safety. This advanced cylinder plays a vital role in supporting the opening rack mechanism, which is crucial for facilitating smooth and reliable movement of the crane’s structure during a variety of lifting tasks.

Enhanced Efficiency and Safety

Designed with precision, the HCYY11112022 Cylinder maximizes both lifting efficiency and safety. Its robust construction can withstand heavy loads and challenging conditions, ensuring that the crane operates smoothly even under pressure. This reliability translates to better performance on the job site, allowing operators to complete tasks quickly and effectively while minimizing the risk of accidents.

Streamlined Installation Process

One of the standout features of the HCYY11112022 is its straightforward installation process. Operators can easily mount the cylinder without extensive training or specialized tools. This ease of installation not only saves time but also empowers operators to confidently manage a range of lifting tasks. With the cylinder in place, users can focus on their work rather than worrying about equipment performance.

Importance of Regular Maintenance

To ensure that the HCYY11112022 remains a dependable asset in your crane operations, regular maintenance and proper usage are essential. Routine inspections help identify potential issues before they escalate, allowing for timely repairs. Keeping the cylinder clean and well-lubricated prevents wear and tear, ensuring long-term functionality. A well-maintained cylinder not only enhances performance but also contributes to the crane’s overall lifespan, making it a wise investment for any operation.

Boosting Productivity and Safety

Investing in the HCYY11112022 Cylinder means enhancing your crane’s capabilities, which leads to increased productivity and improved safety on the job site. With this reliable component, operators can tackle demanding lifting tasks with confidence, knowing that they have the support they need. The result is a safer work environment, where risks are minimized, and efficiency is maximized.

Elevate your operations with the HCYY11112022 Cylinder today. By integrating this high-quality component into your truck crane, you not only enhance its performance but also ensure a safer and more efficient working environment. The combination of robust design, easy installation, and the importance of maintenance makes the HCYY11112022 a smart choice for any crane operator looking to boost productivity and safety on the job site. Don’t miss the opportunity to transform your crane’s capabilities—invest in the HCYY11112022 Cylinder now.

What Maintenance Is Essential For The Hcyy11112022 Cylinder For Opening Rack Support?

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: