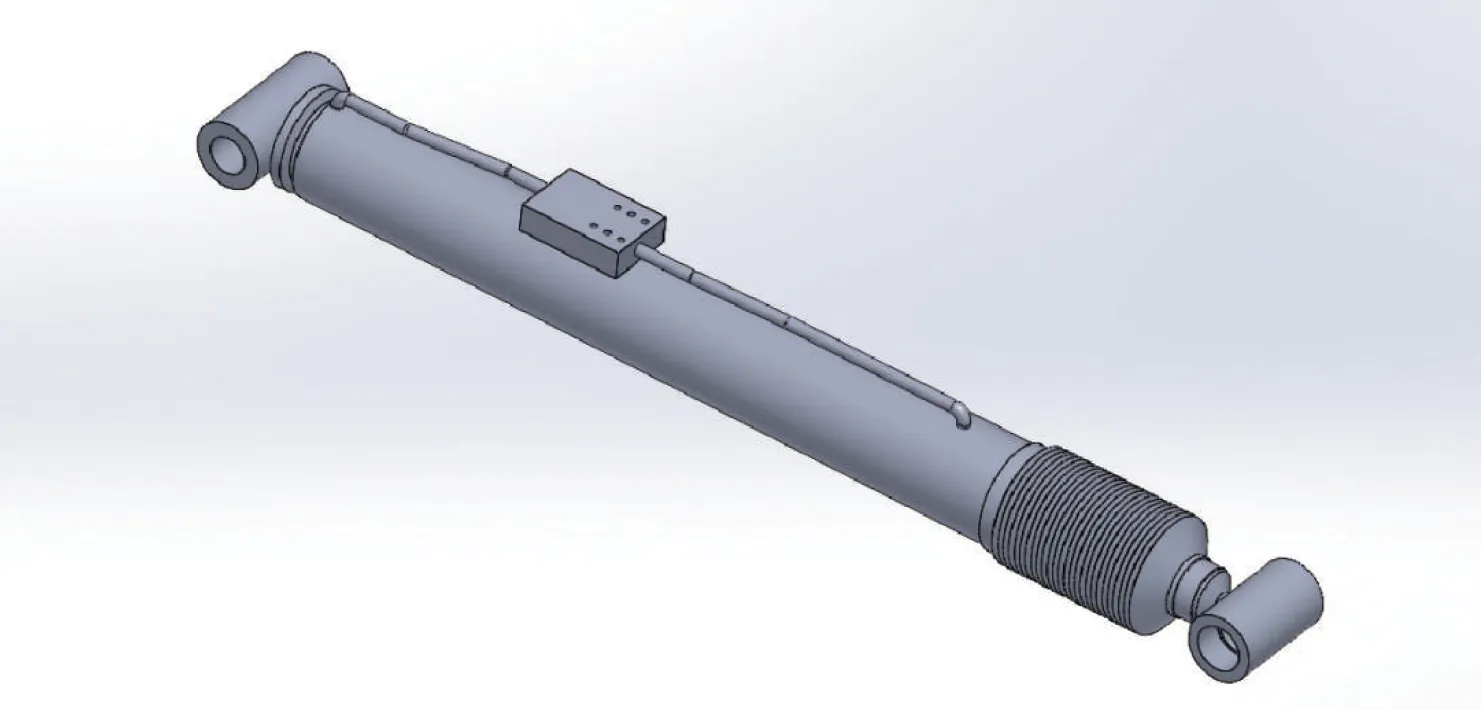

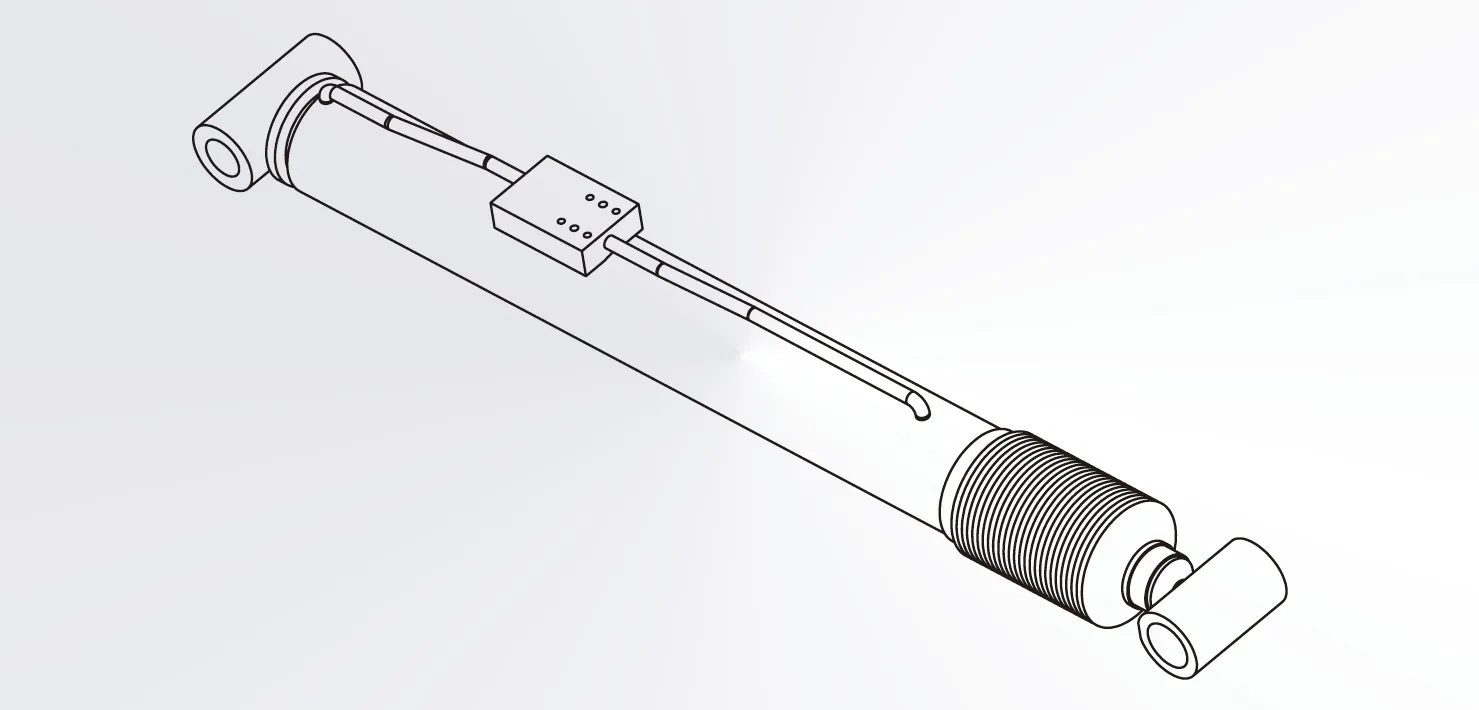

HCYY11112009 Main Boom Extension Cylinder For Aerial Work Vehicles

Як один з виробників, постачальників та експортерів механічних виробів, ми пропонуємо гідравлічні циліндри та багато інших продуктів.

Будь ласка, зв'яжіться з нами для уточнення деталей.

Пошта:sales@hydraulic-cylinders.net

Виробник, постачальник, експортер гідравлічних циліндрів.

HCYY11112009 Main Boom Extension Cylinder For Aerial Work Vehicles

The HCYY11112009 Main Boom Extension Cylinder is a vital component for aerial work vehicles, significantly enhancing their reach and versatility. Specifically engineered for high-performance applications, this cylinder enables operators to effortlessly access elevated areas with precision. Its robust construction and advanced engineering make it an essential tool for construction, maintenance, and various aerial tasks.

With a durable design and improved reach, the HCYY11112009 is a reliable choice for professionals across multiple industries. Integrating this cylinder into your aerial operations not only boosts safety and efficiency but also expands your operational capabilities. By investing in the HCYY11112009, you elevate your work to new heights, ensuring successful outcomes for every project.

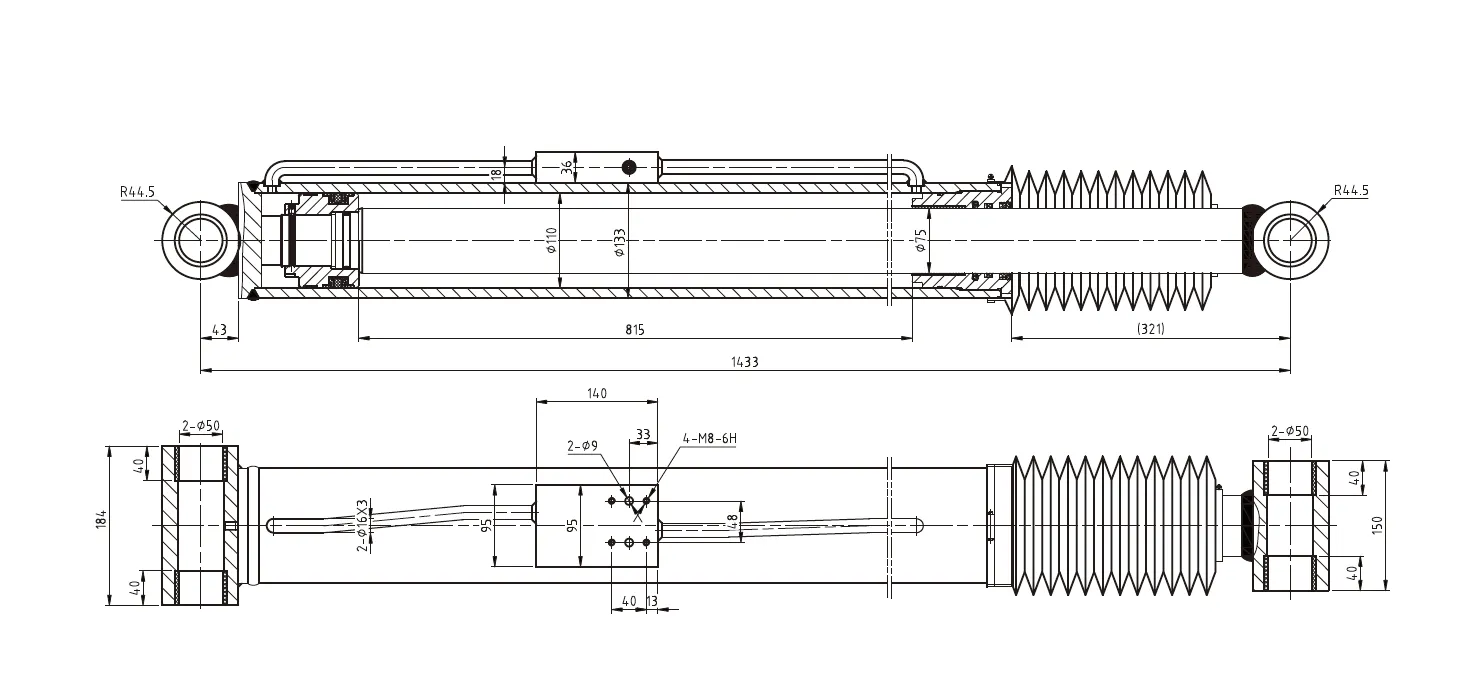

HCYY11112008 Upper Leveling Cylinder For Aerial Work Vehicles Parameter:

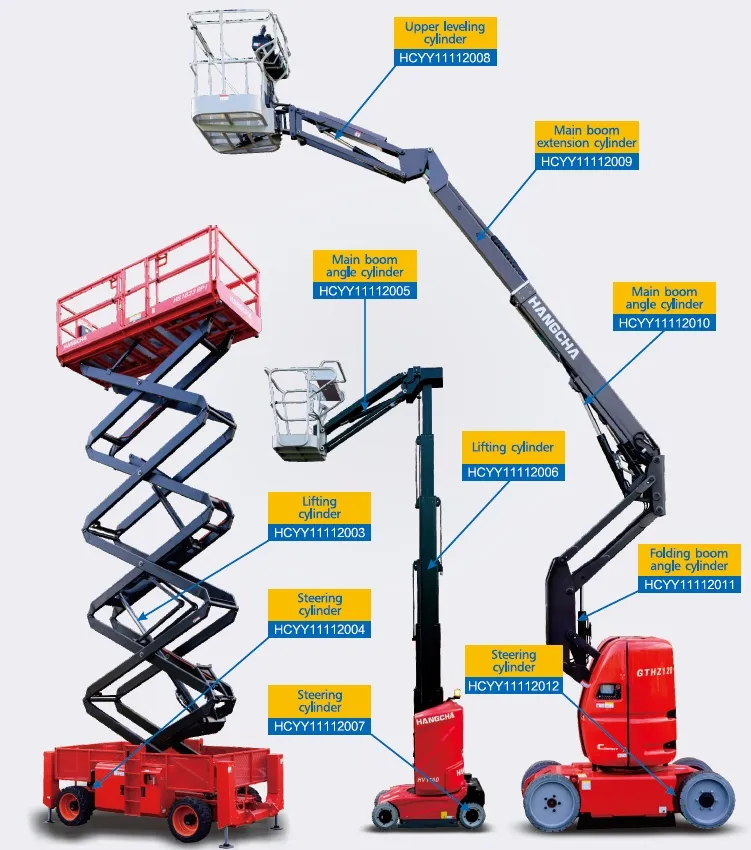

Cylinder Series For Aerial Work Vehicles:

Key Features of HCYY11112009 Main Boom Extension Cylinder For Aerial Work Vehicles:

Durable Construction

The HCYY11112009 is crafted from high-strength materials that are specifically selected to withstand the rigors of harsh environments. This robust construction not only ensures long-lasting performance but also provides the durability needed to handle extreme temperatures, moisture, and abrasive conditions. As a result, operators can rely on this cylinder for consistent performance, reducing the risk of mechanical failures and enhancing overall safety during aerial operations.

Enhanced Reach

One of the standout features of the HCYY11112009 is its ability to significantly extend the boom’s reach. This enhancement allows operators to access difficult spots that would otherwise be challenging or unsafe to reach. Whether working on tall structures, conducting maintenance on elevated equipment, or performing tree trimming, the increased reach ensures that tasks are completed efficiently and safely, minimizing the need for additional equipment or manual labor.

Easy Operation

The intuitive design of the HCYY11112009 makes it exceptionally user-friendly. Operators can easily extend and retract the boom with minimal physical effort, which streamlines workflows and reduces operator fatigue. This ease of operation translates to quicker setup times and a more efficient work process, allowing teams to focus on completing tasks rather than managing complex machinery.

High Load Capacity

With a high load capacity, the HCYY11112009 is engineered to support substantial weights, making it suitable for a variety of applications. This capability allows operators to lift heavy equipment and personnel without compromising safety. The cylinder’s strength ensures that it can handle demanding tasks, providing peace of mind for operators who require reliability in high-stakes situations.

Versatile Compatibility

Designed with versatility in mind, the HCYY11112009 fits a range of aerial work vehicles, enhancing functionality across different models. This adaptability makes it an excellent choice for companies that operate various types of equipment, as it allows seamless integration without the need for extensive modifications. By accommodating multiple vehicle types, the HCYY11112009 maximizes operational efficiency and simplifies equipment management.

In summary, the HCYY11112009 Main Boom Extension Cylinder offers a combination of durability, enhanced reach, ease of operation, high load capacity, and versatile compatibility, making it an indispensable tool for professionals in aerial work.

What Specific Tasks Do You Need The HCYY11112009 Main Boom Extension Cylinder For?

The HCYY11112009 Main Boom Extension Cylinder is ideal for a wide range of tasks, including:

Construction Projects

In construction, the HCYY11112009 allows workers to access elevated areas safely and efficiently. Whether it’s framing, roofing, or installing heavy materials, the extended reach of the cylinder ensures that operators can perform tasks at significant heights without compromising safety. This capability not only speeds up the construction process but also enhances the precision of installations.

Maintenance Work

For maintenance operations, the HCYY11112009 is invaluable when it comes to performing repairs on tall structures, such as buildings, communication towers, and industrial facilities. Its reliable reach enables technicians to access hard-to-reach areas for routine inspections, repairs, or replacements of critical components without the need for scaffolding or additional lifting equipment, thereby increasing productivity and reducing downtime.

Tree Trimming

In landscaping and arboriculture, the HCYY11112009 is essential for safely reaching high branches during tree trimming or removal. By providing operators with the ability to work from a stable platform at height, it minimizes the risk associated with climbing or using ladders. This ensures that trimming is done efficiently and safely, promoting the health and aesthetics of trees in residential or commercial settings.

Telecommunications

The cylinder is also crucial in the telecommunications industry, where it facilitates the installation and maintenance of antennas, wiring, and other equipment on tall poles or towers. By allowing technicians to reach significant heights, the HCYY11112009 ensures that communication infrastructure remains operational and up to date. This capability is vital for maintaining connectivity and service quality in urban and rural areas alike.

Event Setup

In the event management sector, the HCYY11112009 plays a key role in setting up stages, lighting, and other high-profile installations. Its ability to provide safe access to elevated areas allows crews to efficiently position equipment, ensuring that events are executed smoothly and professionally. This not only enhances the visual appeal of the event but also ensures the safety of attendees and performers.

In summary, the HCYY11112009 Main Boom Extension Cylinder is a versatile tool that enhances efficiency and safety across various applications, making it indispensable for professionals in construction, maintenance, landscaping, telecommunications, and event management.

Aerial Work Vehicles Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: