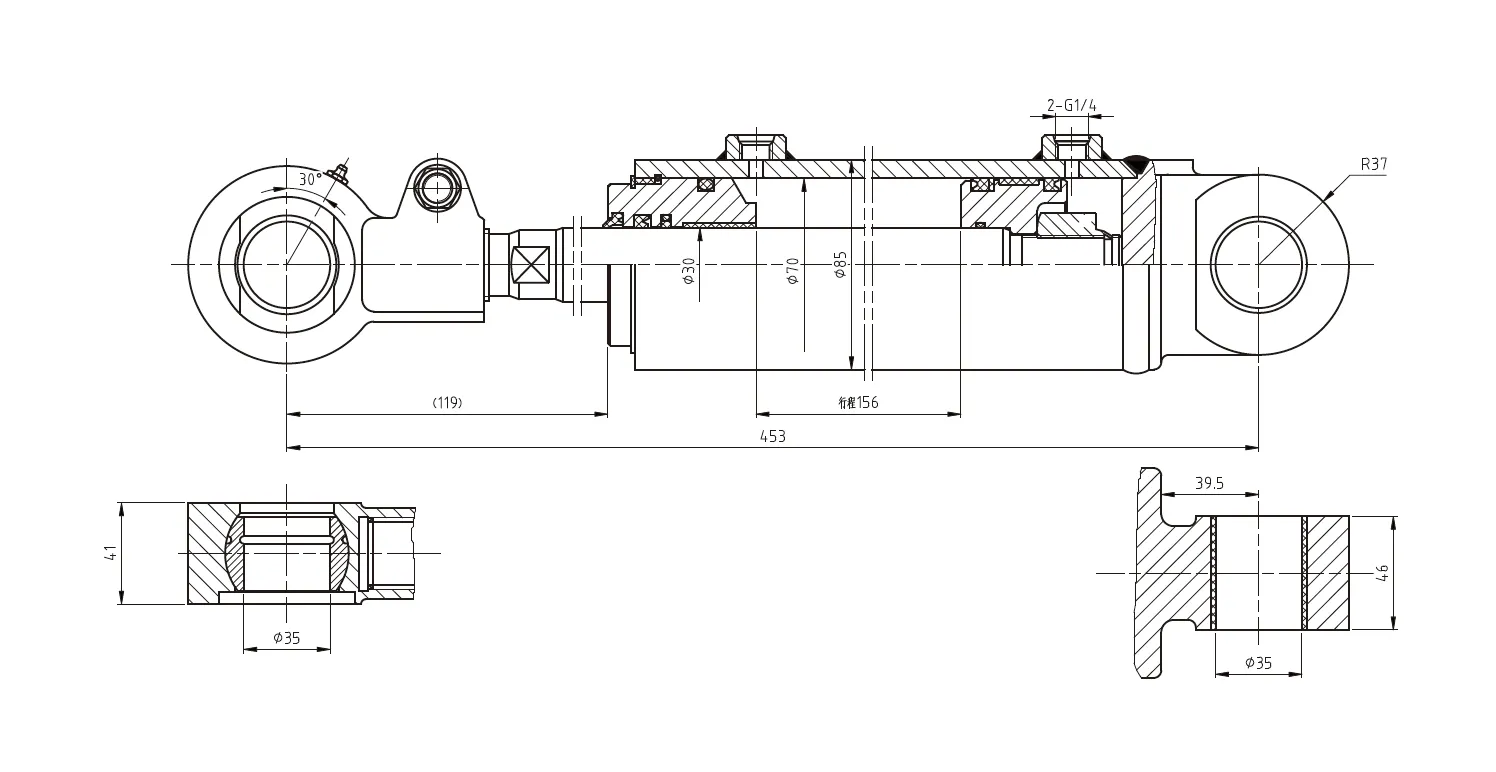

HCYY11112001 Forklift Tilt Cylinder

Як один з виробників, постачальників та експортерів механічних виробів, ми пропонуємо гідравлічні циліндри та багато інших продуктів.

Будь ласка, зв'яжіться з нами для уточнення деталей.

Пошта:sales@hydraulic-cylinders.net

Виробник, постачальник, експортер гідравлічних циліндрів.

HCYY11112001 Forklift Tilt Cylinder

The HCYY11112001 Forklift Tilt Cylinder is an essential powerhouse for any forklift, significantly boosting operational efficiency. This high-performance tilt cylinder ensures smooth and precise tilting of the fork arms, allowing operators to maneuver loads effortlessly and accurately. Whether you’re in a bustling warehouse, on a construction site, or managing a distribution center, this tilt cylinder is key to seamless lifting and stacking operations.

Designed with robustness in mind, the HCYY11112001 Forklift Tilt Cylinder stands out for its impressive load capacity and reliable performance. It’s not just a component; it’s a game changer for productivity across various applications. By adhering to proper usage methods and maintenance practices, you can keep this tilt cylinder performing at its best, enhancing both safety and efficiency in your forklift operations.

Investing in top-tier components like the HCYY11112001 not only elevates your forklift’s performance but also extends the lifespan of your equipment. Experience the difference that quality makes and ensure your operations run smoothly with this indispensable tilt cylinder at the helm!

HCYY11112001 Forklift Tilt Cylinder Parameter:

Forklift Cylinder Series:

Key Features of the HCYY11112001 Forklift Tilt Cylinder:

1. Durable Construction

Crafted from premium-grade materials, the HCYY11112001 Forklift Tilt Cylinder is built to endure the rigors of heavy-duty use and challenging environments. This robust construction ensures the cylinder can withstand impacts, vibrations, and extreme conditions, making it a reliable choice for any operational setting.

2. High Load Capacity

This tilt cylinder is designed with impressive load-bearing capabilities and ensures maximum stability and safety during lifting operations. Its ability to handle substantial loads means you can trust it to perform reliably, whether stacking pallets in a warehouse or lifting materials on a construction site.

3. Smooth Operation

The HCYY11112001 features an advanced hydraulic design that enables seamless tilting. This smooth operation enhances precision in load placement and contributes to increased overall productivity. Operators can adjust the tilt angle effortlessly, allowing for more efficient handling of various materials.

4. Corrosion Resistance

With specially treated surfaces, the HCYY11112001 is designed to resist rust and deterioration. This corrosion resistance significantly extends the lifespan of the cylinder, ensuring that it maintains optimal performance even in humid or chemically aggressive environments. You can count on this component to perform reliably for years to come.

5. Easy Installation

Engineered for straightforward installation, the HCYY11112001 minimizes downtime and maintenance costs. The intuitive design allows for quick setup, so you can get your forklift back in action without unnecessary delays. This ease of installation means less hassle and more productivity for your operations.

6. Versatile Compatibility

The HCYY11112001 is designed to be compatible with a wide range of forklift models, making it a versatile choice for various applications. This adaptability allows businesses to upgrade their existing equipment without worrying about compatibility issues, ensuring seamless integration into your fleet.

7. Enhanced Safety Features

Equipped with built-in safety mechanisms, this tilt cylinder provides peace of mind during operations. Its design prevents unexpected movements, reducing the risk of accidents and ensuring that loads remain secure. Prioritizing safety helps create a more reliable work environment.

By choosing the HCYY11112001 Forklift Tilt Cylinder, you benefit from a product that combines durability, efficiency, and safety, ensuring your forklift operations run smoothly and effectively.

How Does A Forklift Tilt Cylinder Improve Load Handling And Operational Efficiency?

A forklift tilt cylinder transforms load handling and boosts operational efficiency. Here’s how it accomplishes this:

1. Precision Control

The tilt cylinder allows operators to finely adjust the angle of the forks, allowing for meticulous positioning of loads. This precision is essential for preventing drops or misalignments, especially when dealing with heavy or fragile items. Imagine placing a load exactly where it needs to go—this control enhances safety and reduces the risk of expensive damage.

2. Enhanced Stability

The cylinder helps maintain a lower center of gravity for the load by allowing operators to tilt the forks. This increased stability is crucial during lifting and transporting, particularly in busy environments or on uneven surfaces. With better stability, the chances of tipping or swaying are significantly minimized, giving operators confidence in every maneuver.

3. Efficient Stacking

The ability to tilt forks facilitates more efficient stacking of pallets and materials. This capability is especially beneficial in maximizing vertical storage space in warehouses or distribution centers. Operators can easily maneuver loads into tight spots, making the most of every inch of available space and improving overall warehouse organization.

4. Reduced Operator Strain

A well-designed tilt cylinder reduces the physical effort required from operators by enabling optimal positioning of loads with minimal manual intervention. This ergonomic advantage not only decreases operator fatigue but also significantly lowers the risk of workplace injuries. By enhancing comfort, it allows operators to focus on the task at hand, boosting productivity.

5. Accelerated Operations

With the smooth and rapid adjustments provided by tilt cylinders, loading and unloading processes become remarkably faster. This efficiency means quicker turnaround times, which is vital in high-demand environments. Imagine how much more could be accomplished in a shift when every second counts!

6. Versatility in Handling

Tilt cylinders empower forklifts to manage a wide variety of loads, including those with unique shapes or sizes. This versatility eliminates the need for specialized equipment for different tasks, allowing businesses to adapt quickly to changing demands. Whether lifting pallets, containers, or awkwardly shaped materials, the tilt cylinder ensures seamless operation.

7. Improved Safety Features

Many modern tilt cylinders come equipped with built-in safety mechanisms that prevent unexpected movements. This added layer of safety gives operators peace of mind, knowing that loads remain secure during transport. A safer work environment enhances overall team morale and boosts operational efficiency.

In summary, the forklift tilt cylinder is not just a component; it’s a game-changer in material handling operations. By enhancing precision, stability, and versatility, it empowers operators to perform their tasks more efficiently and safely. Investing in high-quality tilt cylinders like the HCYY11112001 can lead to significant improvements in productivity and workplace safety, making them an invaluable asset for any operation.

Forklift Cylinder Production Area:

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line with a designed annual production capacity of million pieces. The special cylinder workshop has semi-automatic cleaning and assembly systems of various specifications with a designed annual production capacity of 200000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high-precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

The machining shop is equipped with custom-made tilt guiderailturning centers, machining centers, high-speed honing machines, welding robots, and other relevant equipment, which can handle the machining work of cylinder tubes with 400mm Max ID and 6 meters of Max length.

We have a fully automatic water-based paint coating line for small and medium cylinders, which realizes automatic loading and unloading and automatic spraying robots with a designed production capacity of 4000 places per shift. We have another semi-automatic painting line for large-scale cylinders driven by a power chain, and the design capacity is 60 crates per shift.

To further improve product performance and establish the leadership position of our hydraulic cylinders in the industry, our company and zjimee jointly established a Comprehensive performance laboratory of hydraulic cylinders, hydraulic valves, and hydraulic pumps; the lab is computer-assisted testing using electro-hydraulic technology, the test conditions are preset by a computer which improves the test accuracy and system versatility, and the experimental data.

The automatic collection is realized through the application of sensors, and the output data, such as the internal leakage and load efficiency of the cylinder or the vale, are directly processed by the computer and converted to standard units (ml/min%). At the same time, to ensure the working safety of the hydraulic system, the state monitoring function is carried out for key performance parameters such as”oil temperature monitoring, liquid level monitoring, filter device monitoring,” etc. Among them, the hydraulic cylinder test stand can test the performance of the “load

efficiency “and” internal leakage” by readings. At the same time, it is equipped with a grating ruler measuring instrument that meets the requirements of all test items of hydraulic cylinder products according to the national standard.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: