CX Series Homotaxial Compact Hydraulic Cylinder

Як один з виробників, постачальників та експортерів механічних виробів, ми пропонуємо гідравлічні циліндри та багато інших продуктів.

Будь ласка, зв'яжіться з нами для уточнення деталей.

Пошта:sales@hydraulic-cylinders.net

Виробник, постачальник, експортер гідравлічних циліндрів.

CX Series Homotaxial Compact Hydraulic Cylinder

The CX series homotaxial compact hydraulic cylinder is a cutting-edge hydraulic component designed to provide efficient and reliable power transmission in a wide range of industrial applications. With its compact design, superior performance, and durability, this hydraulic cylinder offers precise control and versatility. Whether used in manufacturing, material handling, or construction, the CX series homotaxial compact hydraulic cylinder is engineered to optimize hydraulic operations and enhance productivity.

CX series compact cylinders are used for clamping cylinders. Its installation is small. Our factory has advanced hydraulic equipment, including a vertical horizontal machining center, and medium and large hydraulic cylinders. Thin cylinder production technology is excellent.

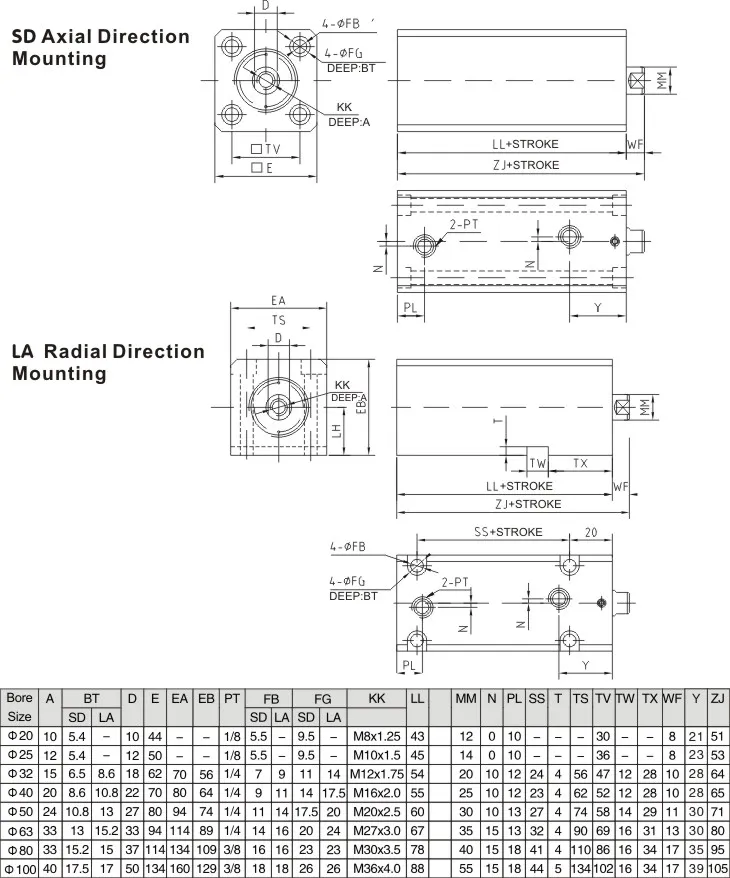

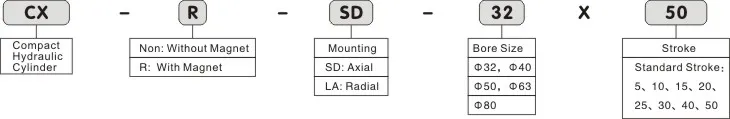

CX Series Homotaxial Compact Hydraulic Cylinder Model Description:

CX Series Homotaxial Compact Hydraulic Cylinder Features:

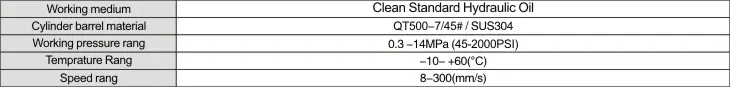

CX Series Homotaxial Compact Hydraulic Cylinder Parameter:

CX Series Homotaxial Compact Hydraulic Cylinder Key Features and Benefits:

- Compact Design:

- The CX Series coaxial compact hydraulic cylinders are designed to take up minimal space, making them ideal for applications where installation areas are limited.

- Its compact size allows seamless integration into a variety of equipment and mechanical Settings.

- Precise Control:

- This hydraulic cylinder provides superior motion and positioning control, enabling accurate and efficient operation.

- The precise control mechanism ensures smooth and controllable movement and improves overall production efficiency.

- High Performance:

- The CX series coaxial compact hydraulic cylinder design provides high-performance power transmission capability.

- It can handle heavy loads and demanding industrial applications, ensuring reliable and consistent performance.

- Versatile Applications:

- The CX series of coaxial compact hydraulic cylinders are designed for multi-purpose applications in manufacturing, material handling, construction, and other industries.

- It can be used in various equipment such as presses, compactors, loaders, etc.

CX Series Homotaxial Compact Hydraulic Cylinder Usage Method:

- Mounting and Installation:

- Determine the appropriate installation location for the CX Series coaxial compact hydraulic cylinders based on the specific requirements of your equipment or machine.

- Ensure that the mounting surface is firm level, and can safely support the weight and load of the cylinder.

- Hydraulic System Connection:

- Connect the hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Proper alignment and tight connections prevent leaks and ensure optimum performance.

- Operating the Cylinder:

- Start the hydraulic system and start the movement of the CX series coaxial compact hydraulic cylinder.

- The hydraulic control system is used to precisely control the cylinder extension, retraction and positioning to achieve efficient operation.

How To Remove Hydraulic Cylinder From Front End Loader?

Removing a hydraulic cylinder from a front-end loader requires proper preparation and caution. Here is a step-by-step guide to help you through the process:

- Ensure Safety:

- Before starting work, park the front-end loader on a flat, stable surface.

- Engage the parking brake and turn off the engine to prevent accidental movement.

- Identify the Cylinder:

- Locate the hydraulic cylinder that needs to be removed. Depending on the loader’s design, there may be multiple cylinders.

- Relieve Hydraulic Pressure:

- To avoid any sudden pressure release, relieve the hydraulic pressure in the system. This step is crucial for safety.

- Start the loader’s engine and operate the hydraulic controls to move the cylinder’s piston fully in one direction.

- Shut off the engine and release residual pressure by operating the controls again.

- Disconnect Hydraulic Lines:

- Locate the hydraulic lines connected to the cylinder. There will typically be a supply line and a return line.

- Place a drain pan beneath the cylinder to catch any hydraulic fluid leaking during disconnection.

- Carefully disconnect the hydraulic lines from the cylinder using appropriate wrenches or fittings. Be prepared for some fluid spillage.

- Support the Cylinder:

- Since hydraulic cylinders can be heavy, it’s essential to provide support before removing them.

- Use a jack, blocks, or any other stable support structure to securely hold the weight of the cylinder.

- Remove Mounting Bolts:

- Identify the mounting points where the cylinder is attached to the loader’s frame or other components.

- Using the appropriate tools, such as wrenches or sockets, remove the mounting bolts or pins that secure the cylinder.

- Keep track of the bolts and any associated hardware for reinstallation.

- Carefully Remove the Cylinder:

- With the hydraulic lines disconnected and the mounting bolts removed, slowly and carefully slide or lift the cylinder out of its mounting position.

- Be mindful of the cylinder’s weight and size to prevent accidents or injuries during removal.

- Inspect and Store:

- Once the cylinder is removed, inspect it for any signs of damage, leaks, or excessive wear. This assessment will help determine if the cylinder needs repair or replacement.

- Clean the cylinder and store it in a clean and dry area to prevent contamination or further damage.

China Hydraulic Cylinder Manufacturers:

HZPT is a company in the R&D and manufacture of compact hydraulic cylinders. It maintains a leading position in China’s market segment of hydraulic cylinders. In 2020, the domestic market share was around 29%. We produce Industrial vehicle compact hydraulic cylinders, Aerial work vehicle compact hydraulic cylinders, agricultural machinery hydraulic cylinders, and sanitation machinery hydraulic cylinders.

We have a first-class independent R&D platform for assembly. The compact hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one fully automatic tilting cylinder assembly line, with a designed annual production capacity of 1 million pieces; the special cylinder workshop is equipped with semi-automatic cleaning and assembly systems of various specifications, with a designed annual production capacity of 200,000 essays. It has famous CNC machining equipment, machining centers, special equipment for high-precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of critical equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

|  |

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: