CX Series Biaxial Compact Hydraulic Cylinder

Як один з виробників, постачальників та експортерів механічних виробів, ми пропонуємо гідравлічні циліндри та багато інших продуктів.

Будь ласка, зв'яжіться з нами для уточнення деталей.

Пошта:sales@hydraulic-cylinders.net

Виробник, постачальник, експортер гідравлічних циліндрів.

CX Series Biaxial Compact Hydraulic Cylinder

The cx Series two-axis compact hydraulic cylinder is a cutting-edge hydraulic element designed to provide efficient and reliable power transmission for a variety of industrial applications. With its compact design, superior performance and durability, this hydraulic cylinder offers precise control and versatility. Whether used in manufacturing, material handling or construction, the cx series of two-axis compact hydraulic cylinders are designed to optimize hydraulic operation and increase productivity.

CX series compact cylinders are used for clamping cylinders. Its installation is small. Our factory has advanced hydraulic equipment, including a vertical, and horizontal machining center and medium and large hydraulic cylinders. Thin cylinder production technology is excellent.

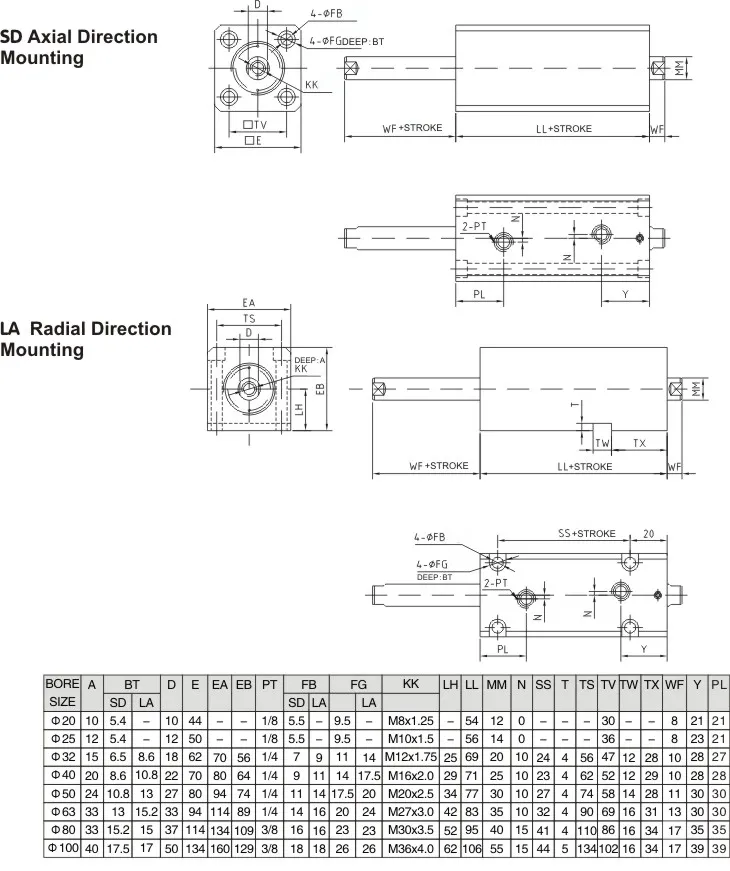

CX Series Biaxial Compact Hydraulic Cylinder Model Description:

CX Series Biaxial Compact Hydraulic Cylinder Features:

CX Series Biaxial Compact Hydraulic Cylinder Parameter:

CX Series Biaxial Compact Hydraulic Cylinder Key Features and Benefits:

- Compact Design:

- The CX Series two-axle compact hydraulic cylinders feature a space-saving design that makes them suitable for applications with limited mounting areas.

- Its compact size allows for easy integration into various device Settings, optimizing space utilization.

- Precise Control:

- This hydraulic cylinder provides superior motion and positioning control, enabling accurate and efficient operation.

- The precise control mechanism ensures smooth and controllable movement and improves overall production efficiency.

- High Performance:

- The CX Series compact two-axis hydraulic cylinders are designed to provide high-performance power transmission capabilities.

- It can handle heavy loads and demanding industrial applications, ensuring reliable and consistent performance.

- Versatile Applications:

- The CX Series two-axle compact hydraulic cylinders are designed for a variety of industries, including manufacturing, material handling, and construction.

- It can be used in various equipment such as presses, compactors, loaders, etc.

CX Series Biaxial Compact Hydraulic Cylinder Usage Method:

- Mounting and Installation:

- Determine the appropriate mounting location for the CX Series two-axle compact hydraulic cylinder based on the specific requirements of your equipment or machine.

- Ensure that the mounting surface is strong, level, and can safely support the weight and load of the cylinder.

- Hydraulic System Connection:

- Connect the hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Proper alignment and tight connections prevent leaks and ensure optimum performance.

- Operating the Cylinder:

- Start the hydraulic system and start the movement of the CX series compact two-axis hydraulic cylinder.

How To Replace Seals In Hydraulic Cylinder?

To remove a hydraulic cylinder from a chair, follow these steps:

- Prepare the Workspace:

- Clear the area around the chair to create a safe and unobstructed workspace.

- Place a protective covering or cloth on the floor to prevent damage to the chair or surrounding surfaces.

- Lower the Chair:

- Use the chair’s adjustment lever or control mechanism to lower it to its lowest position.

- This step ensures that the cylinder is fully compressed, making removing it easier.

- Locate the Cylinder:

- Identify the hydraulic cylinder on the chair. It is typically located near the chair’s base and connects to the seat or the chair’s mechanism.

- Remove the Chair Seat:

- If the chair seat is detachable, locate the mounting screws or bolts that secure it to the cylinder or chair base.

- Use the appropriate tool, such as a screwdriver or wrench, to remove the screws or bolts.

- Lift the seat off the chair, exposing the hydraulic cylinder.

- Support the Chair:

- Since the chair will be unstable without the seat, provide support to prevent it from tipping over.

- Use a sturdy object, such as a box or a wooden block, to prop up the chair’s remaining structure.

- Disconnect the Cylinder:

- Examine the connection points between the hydraulic cylinder and the chair mechanism or base.

- Depending on the chair design, you may find mounting brackets, clips, or screws securing the cylinder.

- Remove any fasteners holding the cylinder in place using the appropriate tools.

- Once the fasteners are removed, gently pull or wiggle the cylinder to detach it from the chair.

- Replace or Dispose of the Cylinder:

- If you are replacing the hydraulic cylinder, ensure you have a compatible replacement that matches the specifications of the old cylinder.

- If necessary, consult the chair manufacturer or a professional to obtain the correct replacement cylinder.

- If you are disposing of the cylinder, follow your local regulations and guidelines for proper disposal.

- Reassemble the Chair:

- Reattach the chair seat by aligning the screw holes and securing them with the appropriate screws or bolts if you removed the chair seat.

- Ensure the seat is firmly attached and stable before using the chair again.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best compact hydraulic cylinder manufacturers. We can offer comprehensive compact hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: