YGD Light Rod Hydraulic Cylinder

Як один з виробників, постачальників та експортерів механічних виробів, ми пропонуємо гідравлічні циліндри та багато інших продуктів.

Будь ласка, зв'яжіться з нами для уточнення деталей.

Пошта:sales@hydraulic-cylinders.net

Виробник, постачальник, експортер гідравлічних циліндрів.

YGD Light Rod Hydraulic Cylinder

YGD light rod hydraulic cylinder is the company’s advantage products, manufacturing experience, mature technology, and cost-effectiveness. The cylinder of the light rod adopts a seamless steel pipe. Different working pressures allow the selection of steel tubes with different wall thicknesses. The inner diameter machining precision is high, the structure is compact, the weight is light, and the installation and connection methods are various. It has the advantages of good low-speed performance, stable buffer performance, and a pressure range of 3.5-17MPA, and it is widely used in machine tools, textiles, plastics, agricultural machinery, and equipment hydraulic systems.

Technical Specification Of YGD Light Rod Hydraulic Cylinder:

1, The use of pressure 5Mpa the following is recommended to use our factory standard low-pressure tie rod hydraulic cylinder, short processing cycle, cost-effective:

2. Minimum pressure: According to the specific application, a particular minimum force is required to ensure the function of the hydraulic cylinder. When there is no load, the recommended minimum pressure of a single-rod hydraulic cylinder is 1MPA.

3, hydraulic cylinder installation: only allow in the case of no pressure, install the hydraulic cylinder, and screw the piston rod end into the machine.

4, treatment agent: no special instructions; The hydraulic cylinder uses a grey primer.

5. Limited by stroke length, cylinder diameter, and rated working pressure, the YGD series tie rod hydraulic cylinder is usually suitable for stroke ≤1.5m, cylinder diameter ≤250mm, and rated pressure PN≤21MPa.

If the cylinder diameter is too large, the rated pressure is too high, or the stroke is too long, it is recommended to use a welding structure;

1) When the rod length is too long, it is easy to deviate during installation, resulting in leakage of the cylinder end.

2) When the inner diameter of the cylinder is too large, or the rated pressure is too high, due to the disassembly problem of the radial size arrangement, the diameter of the tie rod is limited, resulting in the tensile stress of the tie rod may exceed the yield limit.

YGD Light Rod Hydraulic Cylinder:

(1) TB Type Four Rod Hydraulic Cylinder

(2) TC Type Four Rod Hydraulic Cylinder

(3) TD Type Four Rod Hydraulic Cylinder

(4) Front Cover Rectangular Flange Four Rod Hydraulic Cylinder

(5) Rear Cover Rectangular Flange Four Rod Hydraulic Cylinder

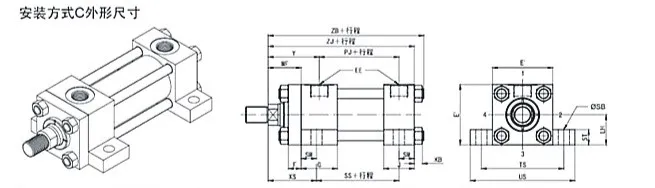

(6) C Type Seat Four Rod Hydraulic Cylinder

(7) Rear Single Earring Four Rod Hydraulic Cylinder

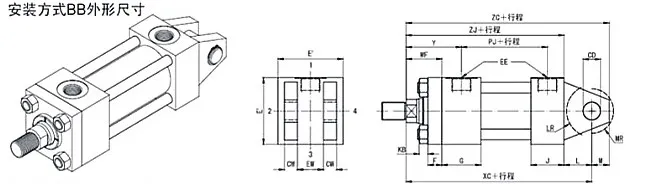

(8) Rear Double Earring Four Rod Hydraulic Cylinder

(9) Rear Earring With Spherical Bearing Four Rod Hydraulic Cylinder

(10) Front Cover Trunnion Four Rod Hydraulic Cylinder

(11) Rear Cover Trunnion Four Rod Hydraulic Cylinder

(12) Middle Fixed Trunnion Four Rod Hydraulic Cylinder

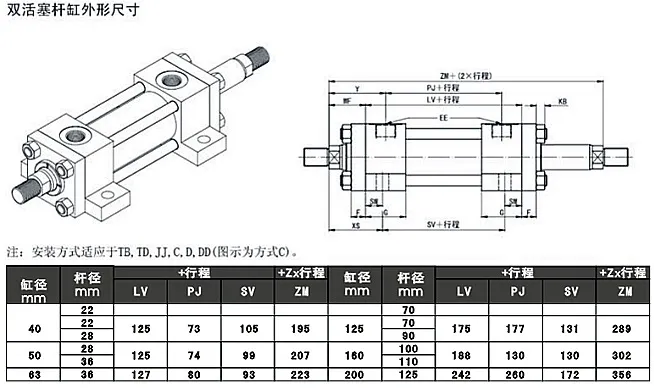

(13) Double Piston Rod Hydraulic Cylinder

Technical Parameter Of Light Rod Hydraulic Cylinder:

YG C-D /d E × 200-TB 4 1 1-y *

C-type :C= differential cylinder; D= constant speed cylinder

D/ D – Cylinder diameter/rod diameter

E – Pressure grade :C=7MPa; E = 16 mpa; D = 21 mpa

200 – Stroke mm

TB – Installation mode :TB= Pull rod extends out of front cover end; TC= pull rod extension back cover end; TD= extension at both ends of the tie rod; JJ= front cover rectangular flange; HH= rear cover rectangular flange; C= side lug (type C seat); B= posterior monaural; BB= back stud; SBd= Back earrings with spherical bearings; D= front cover trunnion; DB= rear cover trunnion; DD= middle fixed trunnion

4 – piston rod end mode :3= non-standard piston rod end; 4= piston rod end external thread; 9= piston rod end internal thread

1-oil connection mode :1= inch internal thread; 2= metric internal thread

1 – Oil port position (see the following figure from the piston rod end)

1 – Buffer position :1= buffer at both ends; 2= no rod-cavity buffer; 3= buffer with rod cavity; 4= No buffer at both ends

Y – The length of the piston rod is measured in millimeters. Write with words. Leave this option blank

Ygc Light Rod Hydraulic Cylinder Characteristics:

Ygc Light Rod Hydraulic Cylinder Installation Method Selection Instructions:

1, Tie rod extension mounting (TB, TC, TD) cylinders are suitable for linear force transmission applications, especially useful in the case of limited space. Cylinder head-end rod mounting is best suited for compression. When the piston rod is stretched, the installation method of the end of the cylinder head should be specified. A cylinder with a pull rod extending from both ends can be fixed to a machine component from either end, while the free end of the cylinder can support a bracket or switch.

2, Fflange-mounted (JJ, HH) cylinders are also suitable for linear force transmission applications. For compression use, cylinder head installation is the most convenient. The cylinder head shall be specified to be installed where the main load causes the piston rod to be stretched.

3, Mounted on the tripod (C) cylinder, does not absorb the force on its center line. As a result, the pressure the cylinder applies creates a tipping moment that attempts to flip the cylinder around the mounting bolt. Therefore, it is essential to secure the cylinder firmly to the mounting surface and guide the load effectively so that the lateral load is not applied to the rod seal and piston guide ring.

4. Hinged cylinders (B, BB, SBd) can absorb the force on their center line and are applied where the machine parts move along the curve. If the bending path of the piston rod is in a plane, two modes of BB and B can be used to fix the cylinder of the earring. For uses where the piston rod will travel along a path on either side of the actual plane of motion, SBd with spherical bearings is recommended.

5, Trunnion mounting (D, DB, DD) cylinders are designed to absorb the force on their center line. They are suitable for tensile (tension) or compression (thrust) purposes and can move machine members along curved paths within a single plane. The trunnion pins are designed for shear loads only and should withstand minimal bending stress.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best heavy rod hydraulic cylinder manufacturers. We can offer comprehensive heavy rod hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: