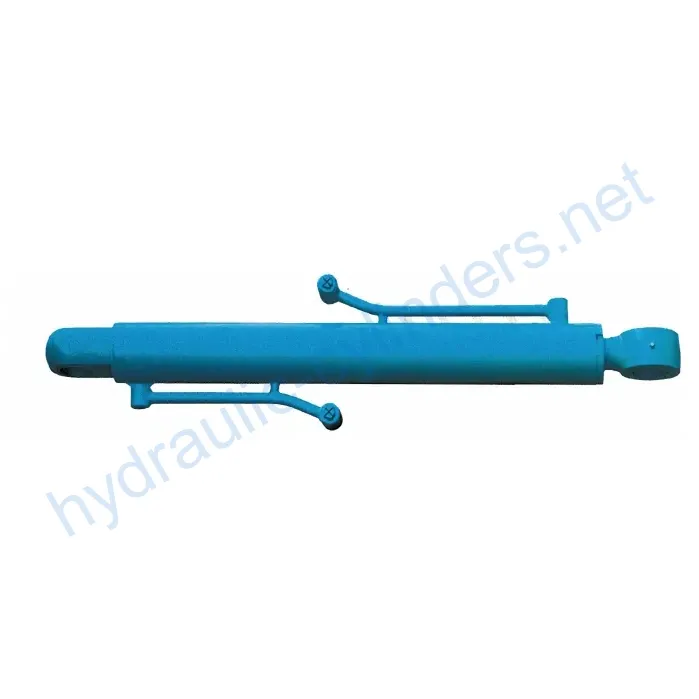

Bucket Cylinder For Caterpillar Small Excavator E70/70B

Hidrolik silindir üreticilerinden, tedarikçilerinden ve mekanik ürünlerin ihracatçılarından biri olarak, hidrolik silindirler ve diğer birçok ürünü sunuyoruz.

Ayrıntılar için lütfen bizimle iletişime geçin.

Posta:sales@hydraulic-cylinders.net

Hidrolik silindir üreticisi tedarikçisi ihracatçısı.

Bucket Cylinder For Caterpillar Small Excavator E70/70B

Introduction

A bucket cylinder is a specially designed hydraulic cylinder primarily used to control the movement of the bucket in heavy machinery such as excavators, backhoes, and front-end loaders. Its main function is to enable the bucket to perform lifting, lowering, and tilting operations, making it convenient for various material handling tasks. In the hydraulic system, the bucket cylinder achieves precise control of the bucket through changes in hydraulic oil pressure, allowing operators to handle heavy loads efficiently and adapt to complex working environments and diverse operational requirements.

Features

- High strength and durability: Generally made of high-strength steel or aluminum, can withstand high pressure and heavy loads, suitable for harsh working environments, designed with wear resistance and corrosion resistance in mind, extending the service life.

- Efficient hydraulic operation: Smooth extension and retraction actions are achieved by utilizing the pressure of hydraulic oil, allowing for quick response to control commands, providing powerful pushing and pulling forces, and suitable for handling heavy loads and complex operational tasks.

- Diverse types: Single-acting (hydraulic used in one direction only) or double-acting (hydraulic used in both directions) cylinders can be chosen according to the needs to meet different operational requirements. Some models are telescopic, allowing for greater extension without increasing external dimensions, suitable for applications with limited space.

- Easy to install: Can be easily installed in place of the original cylinder, saving time and labor costs. Customizable according to customer requirements.

- Universal compatibility: Can replace various hydraulic cylinders, providing a cost-effective solution for equipment maintenance and repair.

Applications

The bucket cylinder is widely used in various heavy machinery, including:

- Construction Equipment: In excavators, they are essential for digging, loading, and moving soil or debris. In backhoes, bucket cylinders assist in digging and lifting.

- Agricultural Machinery: Used in front-end loaders for scooping, lifting, and transporting soil, hay, and other materials.

- Material Handling Equipment: Used in forklifts and other industrial vehicles to lift, transport, and stack goods.

Design Considerations and Selection Criteria

The design of the bucket cylinder is crucial to its performance and durability. Key considerations include:

- Bearing capacity: The cylinder must be able to handle the expected load without failure or damage.

- Sealing: The cylinder must be sealed to prevent leaks and contamination.

- Durability: The cylinder must be able to withstand the expected wear and tear from use in harsh environments.

- Safety: The cylinder must be designed with safety features to prevent accidents and injuries.

- Maintainability: The cylinder must be designed for easy maintenance and repair.

Sealing and Lubrication

The bucket cylinder uses various sealing components such as piston seal rings and rod seal rings made of wear-resistant materials such as polyurethane and nitrile rubber. The cylinder body and threaded end surfaces are finely processed to improve wear resistance. Regular lubrication with the appropriate hydraulic oil is necessary to ensure smooth operation and prolong the service life of the cylinder.

Maintenance and Repair

Regular inspection, lubrication, and replacement of seals are essential for maintaining the bucket cylinder’s performance and extending its service life. Proper installation, lubrication, and adjustment are critical to ensure the cylinder’s efficient operation and prevent damage or failure. It is recommended to use appropriate installation brackets to fix the cylinder in place and follow the recommended inspection, repair, and replacement procedures to ensure proper function and safety.

Safety and Environmental Considerations

When using the bucket cylinder, it is essential to follow proper safety procedures to prevent accidents and injuries. Regular maintenance and inspection can also help prevent environmental contamination from fluid leaks or other damage to the cylinder.

Troubleshooting and Common Issues

Common problems with the bucket cylinder include leakage, decreased performance, and improper operation. Proper diagnosis and repair of these issues require experience and expertise and should only be performed by trained professionals. Regular maintenance and inspection can help prevent these issues from occurring.

About Our Company

We are a manufacturer of replacement hydraulic cylinders and a leading manufacturer and wholesaler of hydraulic cylinders in the domestic and international markets. We follow the principle of excellence in quality and rely on industrialized production management strategies in fine manufacturing workshops. Our company constantly improves the production platform of the workshop from the application of technical talents, digital high-end manufacturing equipment, and professional testing systems to improve the quality production route of the product. Our company has a strong creative ability and is based on the principles of high efficiency, high accuracy, and high quality to meet the diverse needs of customers.

- Professionalism: Our team of experts provides professional services and technical support to customers from various industries.

- International Certification: Our products have passed various international certifications such as ISO and CE.

- Customization services: We provide customized hydraulic cylinders according to customer requirements and specifications.

- Production Equipment: We use advanced manufacturing equipment to ensure product quality and precision.

- After-sales Service: We provide timely and efficient after-sales service to ensure customer satisfaction.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: