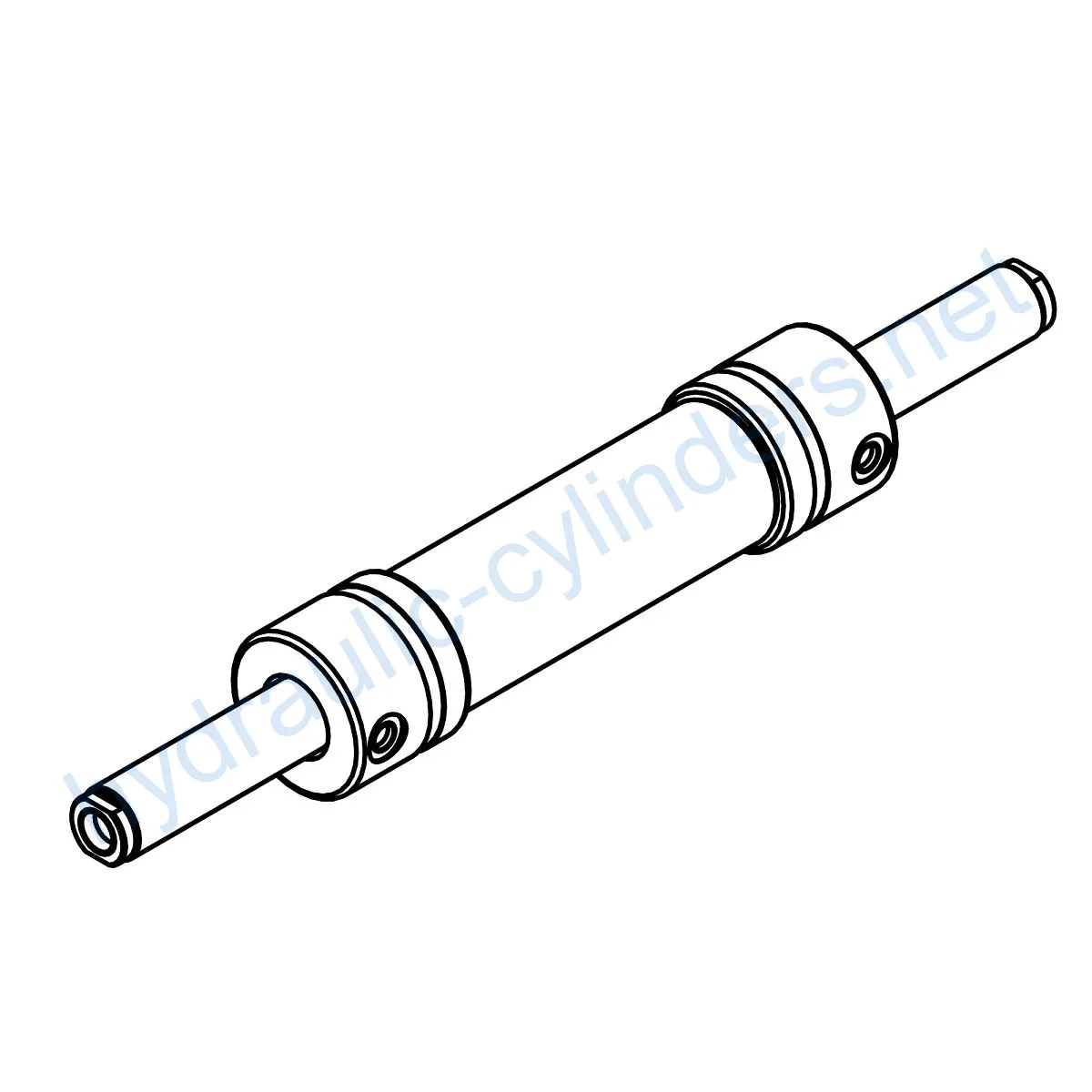

Replacement Of SJ31116 Hydraulic Steering Cylinder

Kot eden od proizvajalcev, dobaviteljev in izvoznikov hidravličnih cilindrov ponujamo hidravlične cilindre in številne druge izdelke.

Za podrobnosti se obrnite na nas.

Pošta:sales@hydraulic-cylinders.net

Proizvajalec, dobavitelj in izvoznik hidravličnih cilindrov.

Introduction

The Replacement Of SJ31116 Hydraulic Steering Cylinder is a crucial component in hydraulic systems. It functions to convert hydraulic power into mechanical force, allowing for precise control and movement of machinery. The cylinder has a weight of 21.86 lbs, a height of 4 inches, and a length of 26 inches. It is compatible with various John Deere models, including 5E-5310 5045E 5050E 5055E 5058E 5060E 5065E 5067E 5075E.

Specifications and Compatibility

The Replacement Of SJ31116 Hydraulic Steering Cylinder has a weight of 21.86 lbs, a height of 4 inches, and a length of 26 inches. It is compatible with various John Deere models, including 5E-5310 5045E 5050E 5055E 5058E 5060E 5065E 5067E 5075E.

Features

- Restores equipment performance: Replacing damaged or worn hydraulic cylinders can restore equipment’s normal operating capability, ensuring its performance in various applications.

- Enhances safety: Regularly replacing hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

- Overload protection: New cylinder designs usually consider better overload protection mechanisms, improving safety.

- Quick installation: Modern hydraulic cylinder designs typically consider ease of installation and replacement, reducing downtime.

- Standardized components: Many hydraulic cylinders are standardized products, making it easy to obtain replacement parts in the market.

We are able to produce and supply a perfect replacement product for these hydraulic cylinders.

Applications

The Replacement Of SJ31116 Hydraulic Steering Cylinder is used in various machinery, including:

Excavators

In excavator booms or buckets, hydraulic cylinders may become damaged due to long-term use or overload and need to be replaced to restore normal operation.

Cranes

The crane’s boom hydraulic cylinder is prone to wear and tear due to frequent lifting and lowering and needs to be replaced regularly to ensure safety.

Tractors

The front-end loader hydraulic cylinder of a tractor may leak or lose performance due to continuous lifting and tilting operations and needs to be replaced.

Harvesters

During harvesting, the hydraulic system experiences high pressure, and cylinders may become damaged due to fatigue, requiring timely replacement to maintain work efficiency.

Automated production lines

Hydraulic cylinders are used to control robotic arms and other automation equipment. Cylinder failure can affect production efficiency and requires immediate replacement.

Die-casting machines

Under high-pressure and high-temperature environments, hydraulic cylinders may experience performance degradation. Regular replacement can ensure product quality.

Mining equipment

Hydraulic cylinders are used in mining equipment to lift and move heavy objects. Due to the harsh working environment, regular inspection and replacement are necessary to avoid equipment failure.

Bulldozers

The wear and tear of the hydraulic cylinder on the bulldozer’s pusher arm can cause a decrease in pushing capacity and require immediate replacement to maintain work efficiency.

Maintenance

Regular maintenance is critical to the longevity and optimal performance of hydraulic cylinders. The following are three common maintenance tasks:

Inspection

Regular inspection of hydraulic cylinders can prevent issues and increase their lifespan. Inspection should include checking for leaks and other signs of wear and tear.

Lubrication

Proper lubrication is critical to hydraulic cylinder performance. It would help if you used the correct lubricant and regularly apply it to the cylinder to reduce friction and wear.

Seal replacement and calibration check

Seal replacement and calibration check are critical to maintain cylinder performance. You should replace seals before they are worn out and regularly check calibration to ensure optimal performance.

Proper installation, lubrication, and adjustment are crucial to hydraulic cylinder performance. During installation, it’s important to provide proper alignment guidance and use appropriate installation brackets to secure the cylinder. Recommended inspection, repair, and replacement procedures are essential to increase the life of hydraulic cylinders.

Safety and Environmental Considerations

When working with hydraulic cylinders, safety measures are essential. It’s essential to follow safety guidelines and the manufacturer’s recommendations. Proper handling, inspection, and maintenance of hydraulic cylinders are critical to ensure safety and environmental protection.

Common Problems and Troubleshooting

Common problems with hydraulic cylinders include leaks, seal damage, and performance degradation. Troubleshooting these issues can involve inspecting seals and other components, checking calibration, and replacing damaged parts. To prevent issues, regular inspection and maintenance are essential.

Design Considerations and Selection Criteria

Hydraulic cylinder design considerations include bearing capacity, sealing, durability, safety, and maintainability. Choosing the right hydraulic cylinder requires considering operating conditions, load capacity, and the environment. Proper sealing and lubrication are essential to maintain the longevity and optimal performance of hydraulic cylinders.

About Our Company

We are a leading manufacturer and wholesale distributor of hydraulic cylinders, providing a full range of replacement products. We are renowned for our expertise, international certifications, customized services, production equipment, and after-sales service.

Author: lyl

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: