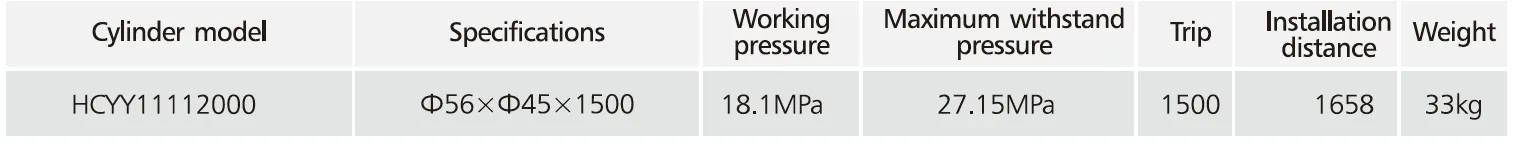

HCYY11112000 Forklift Lifting Cylinder

Kot eden od proizvajalcev, dobaviteljev in izvoznikov hidravličnih cilindrov ponujamo hidravlične cilindre in številne druge izdelke.

Za podrobnosti se obrnite na nas.

Pošta:sales@hydraulic-cylinders.net

Proizvajalec, dobavitelj in izvoznik hidravličnih cilindrov.

HCYY11112000 Forklift Lifting Cylinder

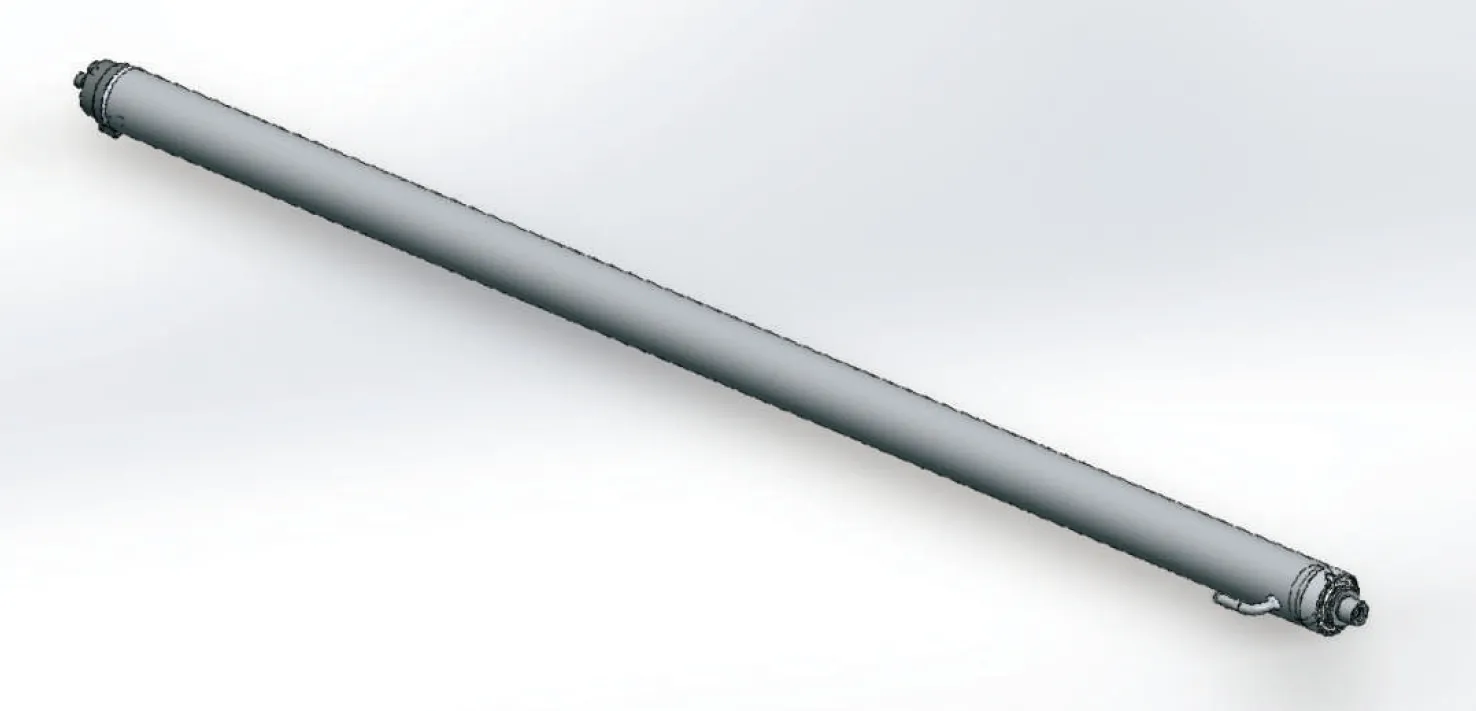

The HCYY11112000 Forklift Lifting Cylinder is a crucial component for forklift operations, facilitating the efficient lifting and lowering of heavy loads. Engineered for durability and high performance, this hydraulic cylinder significantly boosts productivity across various industrial environments.

As an essential asset for any forklift operation, the HCYY11112000 features a robust design and high load capacity, making it an ideal choice for industries such as warehousing and construction. By familiarizing themselves with its features, proper usage, and maintenance requirements, operators can ensure that this hydraulic cylinder provides reliable service and enhances productivity for years.

HCYY11112000 Forklift Lifting Cylinder Parameter:

Forklift Cylinder Series:

Key Features of the HCYY11112000 Forklift Lifting Cylinder:

The HCYY11112000 Forklift Lifting Cylinder is designed with several standout features that enhance its performance and reliability in demanding industrial settings.

High Load Capacity

Engineered for heavy-duty applications, the HCYY11112000 can effortlessly handle substantial weights. This high load capacity ensures that operators can lift and transport large materials with confidence, making it an invaluable tool in warehouses, construction sites, and manufacturing plants.

Durable Construction

Crafted from high-strength materials, this cylinder boasts exceptional durability. Its robust design resists wear and tear, allowing it to withstand the rigors of daily use. This durability translates into a longer service life, reducing the need for frequent replacements and minimizing operational costs.

Precision Engineering

The HCYY11112000 features an innovative design that promotes smooth and accurate lifting. This precision engineering minimizes the risk of load shifting, enhancing safety during operations. Operators can rely on this cylinder to maintain stability, even when lifting uneven or bulky loads.

Corrosion Resistance

In challenging environments, exposure to moisture and harsh chemicals can lead to premature deterioration. The HCYY11112000 is equipped with special coatings that provide effective protection against rust and corrosion. This feature ensures reliable operation and extends the lifespan of the cylinder, regardless of the conditions it faces.

Efficient Operation

An optimized hydraulic flow design enhances the lifting speed and efficiency of the HCYY11112000. This thoughtful engineering reduces downtime, allowing operators to complete tasks more quickly and efficiently. The enhanced performance not only saves time but also improves overall productivity in fast-paced work environments.

Versatile Application

The HCYY11112000 is versatile enough to be used in various applications, from lifting heavy industrial components to handling pallets in a warehouse. Its adaptability makes it a preferred choice across multiple industries, ensuring that it meets the diverse needs of operators.

Easy Installation and Maintenance

Designed with user-friendliness in mind, the HCYY11112000 allows for straightforward installation and maintenance. Operators can quickly set it up and perform regular checks, ensuring smooth functionality without extensive downtime.

With its impressive features, the HCYY11112000 Forklift Lifting Cylinder not only enhances lifting efficiency but also elevates safety and durability standards. By investing in this high-performance cylinder, industries can boost productivity and ensure reliable operations for years.

What Key Maintenance Practices Help Extend The Life Of A Forklift Lifting Cylinder?

To significantly extend the life of a forklift lifting cylinder, it’s essential to adopt a proactive maintenance approach. Here are some key practices that not only enhance longevity but also ensure safe and efficient operations:

1. Regular Inspections

- Why It Matters: Frequent inspections are crucial for identifying wear, leaks, or damage early on. Catching these issues before they escalate can save on costly repairs and downtime.

- Tip: Create a checklist to systematically inspect all components, including hoses, seals, and the cylinder itself.

2. Hydraulic Fluid Checks

- Why It Matters: The hydraulic fluid acts as the lifeblood of the lifting cylinder, enabling smooth operation. Maintaining proper fluid levels and quality is vital for optimal performance.

- Tip: Regularly check for contamination and replace the fluid according to the manufacturer’s recommendations.

3. Seal Maintenance

- Why It Matters: Seals play a critical role in preventing leaks and maintaining pressure within the cylinder. Worn or damaged seals can lead to performance issues and safety hazards.

- Tip: Inspect seals during regular checks and replace them promptly to avoid more significant problems.

4. Cleaning

- Why It Matters: Keeping the cylinder and surrounding areas free of dirt and debris is essential to prevent contamination and ensure smooth operation.

- Tip: Use a soft cloth and appropriate cleaning agents to avoid damaging the surface while ensuring that the area remains clean.

5. Lubrication

- Why It Matters: Proper lubrication of moving parts reduces friction and wear, which can prolong the life of the cylinder.

- Tip: Follow the manufacturer’s guidelines for lubricants and ensure that all moving parts are adequately serviced.

6. Load Management

- Why It Matters: Operating within the specified load capacity is crucial for safety and efficiency. Overloading can lead to mechanical failure and increased wear.

- Tip: Always be aware of the load limits and train operators to recognize the importance of adhering to them.

7. Professional Servicing

- Why It Matters: Engaging professionals for regular maintenance checks can help identify potential issues that might not be apparent during routine inspections.

- Tip: Establish a maintenance schedule with a certified technician to ensure all components are in top condition.

By integrating these essential maintenance practices into your routine, you enhance the longevity of your forklift lifting cylinder and improve safety and efficiency across your operations. A well-maintained lifting cylinder can lead to increased productivity, reduced operational costs, and a safer workplace, making these practices well worth the effort!

Forklift Cylinder Production Area:

We have a first-class independent R&D platform for assembly. The forklift cylinder production workshop has four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line with a designed annual production capacity of million pieces. The special cylinder workshop has semi-automatic cleaning and assembly systems of various specifications with a designed annual production capacity of 200000 pieces. It is equipped with famous brand CNC machining equipment, machining centers, special equipment for high-precision cylinder processing, robot welding machines, automatic cleaning machines, automatic cylinder assembly machines, and automatic paint production lines. We have more than 300 sets of key equipment running. The optimized allocation and efficient utilization of equipment resources ensure the precision requirements of the products and meet the high standard quality requirements of the products.

The machining shop is equipped with custom-made tilt guiderailturning centers, machining centers, high-speed honing machines, welding robots, and other relevant equipment, which can handle the machining work of cylinder tubes with 400mm Max ID and 6 meters of Max length.

We have a fully automatic water-based paint coating line for small and medium cylinders, which realizes automatic loading and unloading and automatic spraying robots with a designed production capacity of 4000 places per shift. We have another semi-automatic painting line for large-scale cylinders driven by a power chain, and the design capacity is 60 crates per shift.

To further improve product performance and establish the leadership position of our hydraulic cylinders in the industry, our company and zjimee jointly established a Comprehensive performance laboratory of hydraulic cylinders, hydraulic valves, and hydraulic pumps; the lab is computer-assisted testing using electro-hydraulic technology, the test conditions are preset by a computer which improves the test accuracy and system versatility, and the experimental data.

The automatic collection is realized through the application of sensors, and the output data, such as the internal leakage and load efficiency of the cylinder or the vale, are directly processed by the computer and converted to standard units (ml/min%). At the same time, to ensure the working safety of the hydraulic system, the state monitoring function is carried out for key performance parameters such as”oil temperature monitoring, liquid level monitoring, filter device monitoring,” etc. Among them, the hydraulic cylinder test stand can test the performance of the “load

efficiency “and” internal leakage” by readings. At the same time, it is equipped with a grating ruler measuring instrument that meets the requirements of all test items of hydraulic cylinder products according to the national standard.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: