HCYY11112010 Main Boom Angle Cylinder For Aerial Work Vehicles

Ako jeden z výrobcov, dodávateľov a vývozcov mechanických výrobkov ponúkame hydraulické valce a mnoho ďalších výrobkov.

Kontaktujte nás, ak chcete získať podrobné informácie.

Pošta:sales@hydraulic-cylinders.net

Výrobca dodávateľ vývozca hydraulických valcov.

HCYY11112010 Main Boom Angle Cylinder For Aerial Work Vehicles

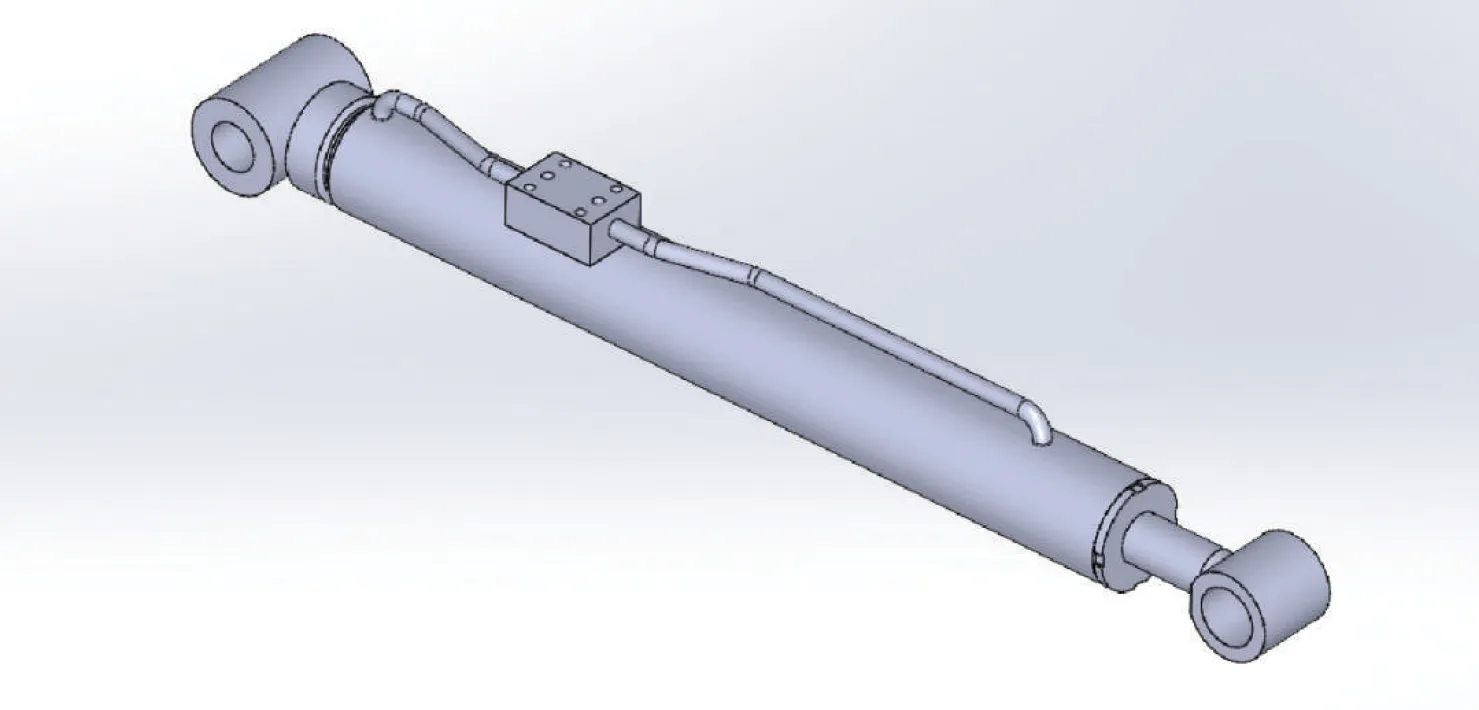

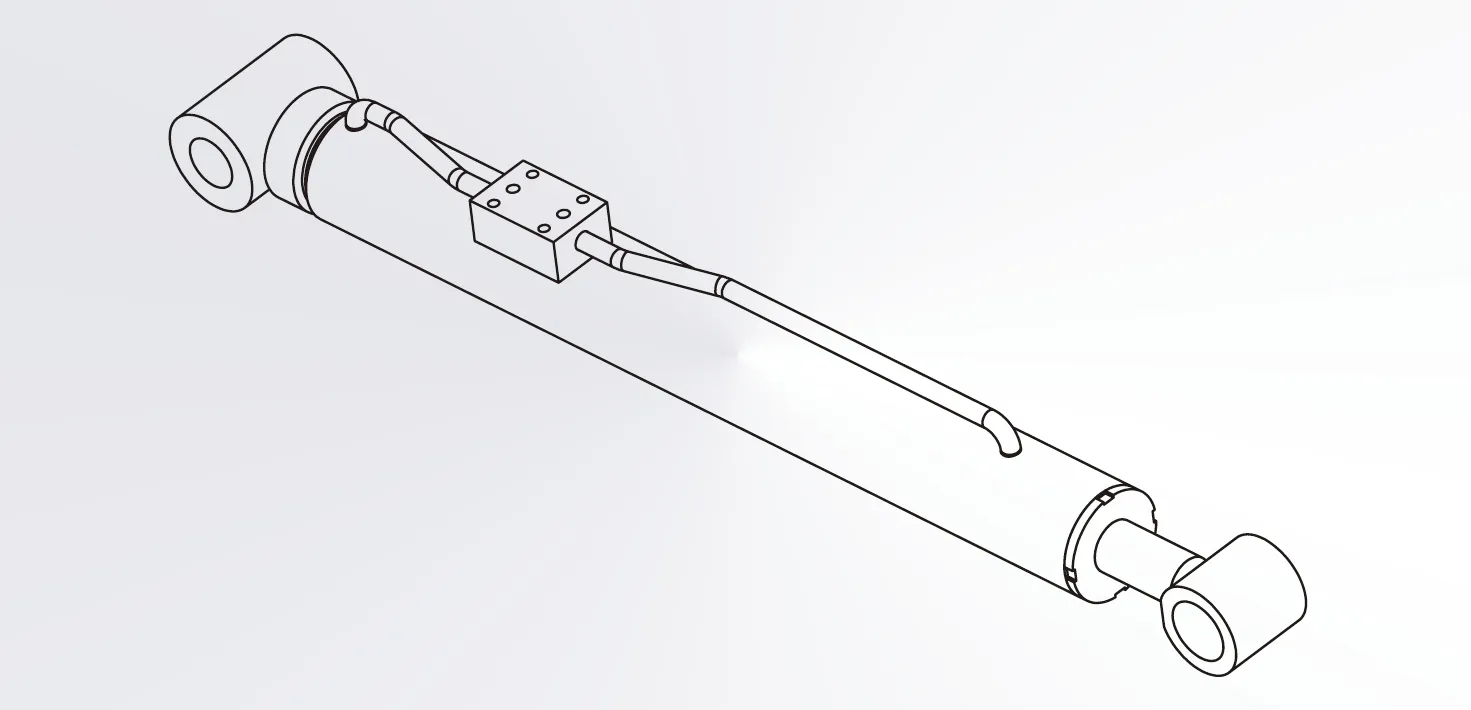

The HCYY11112010 Main Boom Angle Cylinder is an advanced component specifically engineered for aerial work vehicles. This cylinder significantly enhances the maneuverability and functionality of aerial platforms, making it indispensable across various industries, including construction, maintenance, and telecommunications. With its robust design and cutting-edge engineering, the HCYY11112010 guarantees safe and efficient operation at elevated heights.

This cylinder is crucial for improving both safety and efficiency in aerial work applications. Its durable construction, user-friendly design, and precise functionality meet the demanding needs of professionals in diverse fields. By adhering to proper usage and maintenance guidelines, operators can ensure that the HCYY11112010 consistently delivers reliable performance, streamlining aerial operations and enhancing effectiveness.

Investing in the HCYY11112010 not only boosts your aerial work capabilities but also elevates the overall performance of your equipment, enabling you to tackle tasks with confidence and precision.

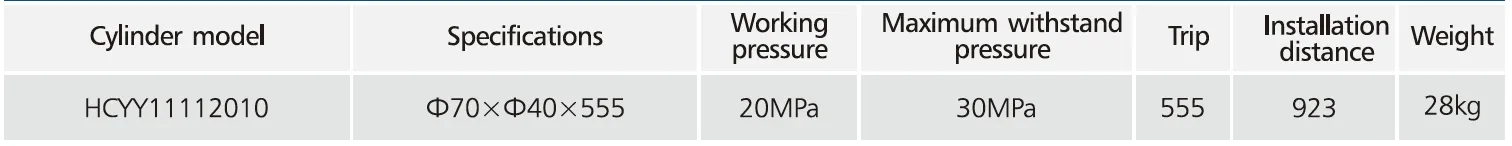

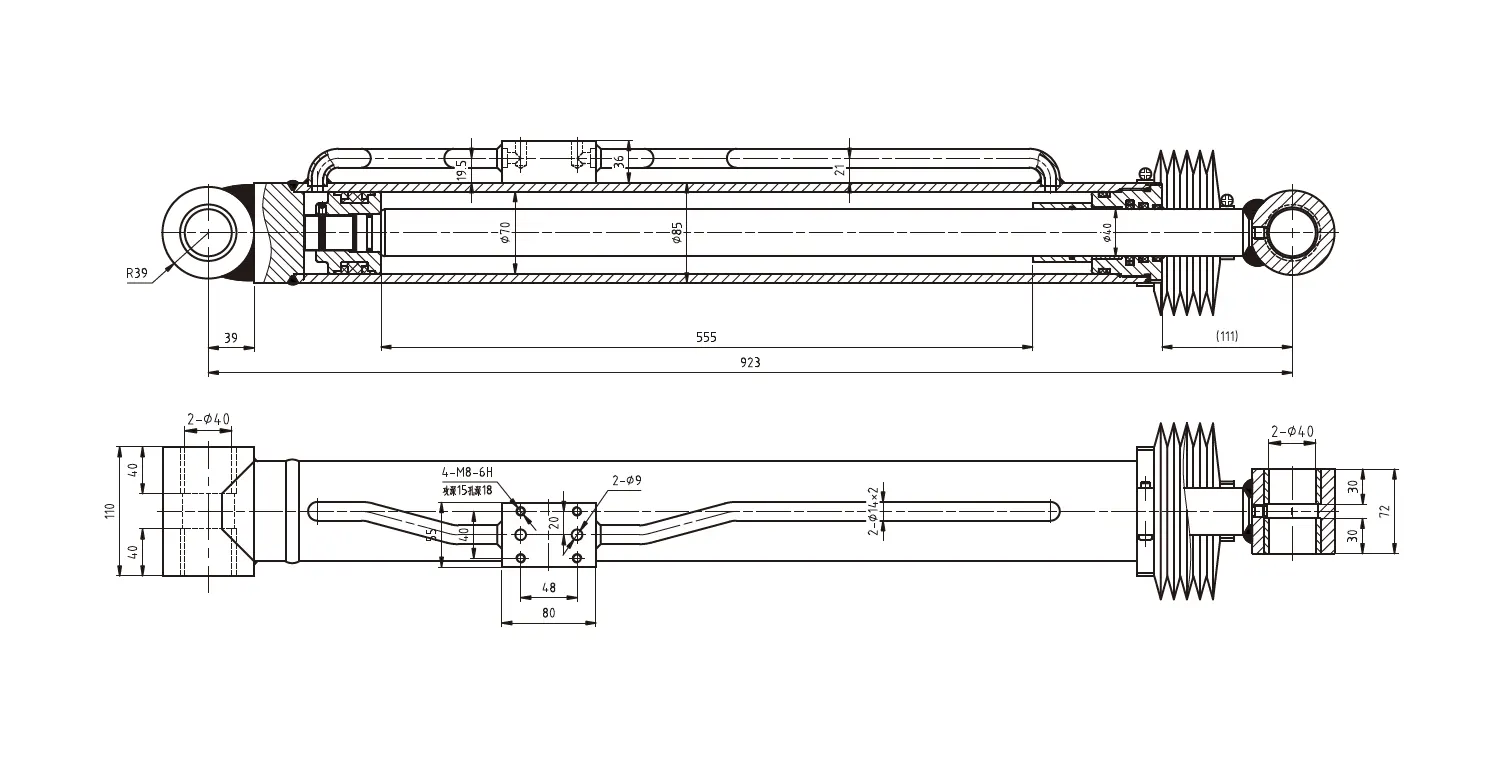

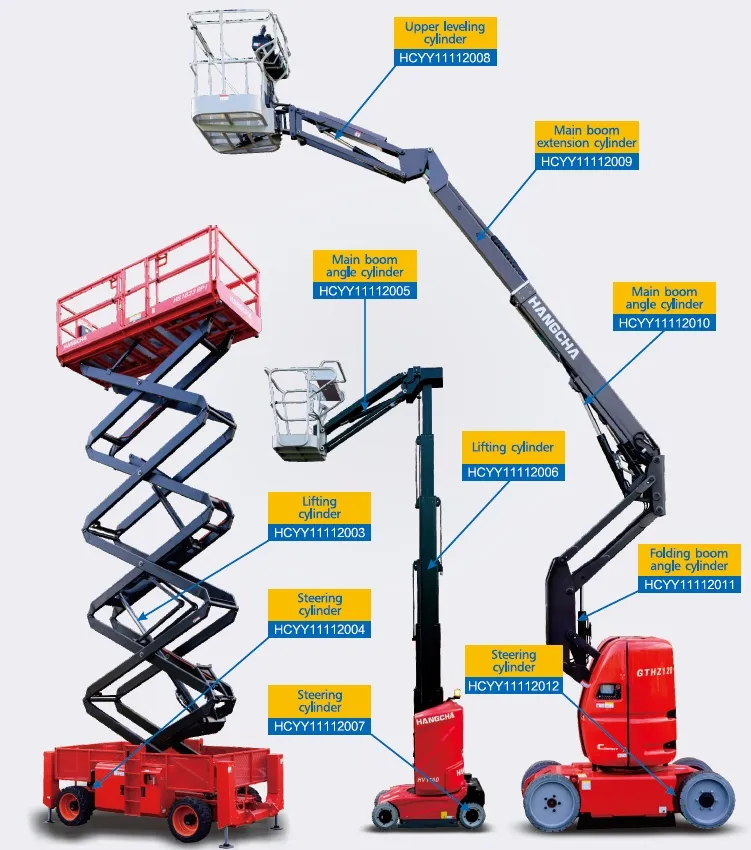

HCYY11112010 Main Boom Angle Cylinder For Aerial Work Vehicles Parameter:

Cylinder Series For Aerial Work Vehicles:

Key Features of HCYY11112010 Main Boom Angle Cylinder For Aerial Work Vehicles:

Regular Inspections

Conducting routine inspections is vital for maintaining the HCYY11112010 Main Boom Angle Cylinder’s performance and safety. Check for visible wear on seals and hoses, inspect for hydraulic leaks, and look for any signs of damage, such as dents or corrosion. Early detection of these issues allows for timely repairs, preventing further damage and ensuring the cylinder operates effectively.

Lubrication

Proper lubrication is essential for the longevity of the HCYY11112010. Apply the recommended lubricants to moving parts regularly, as specified by the manufacturer. This practice reduces friction, minimizes wear, and enhances the smooth operation of the cylinder. Ensure that lubrication points are easily accessible and that excess lubricant is wiped away to prevent contamination.

Hydraulic Fluid Levels

Monitoring hydraulic fluid levels is crucial for optimal operation. Regularly check the fluid reservoir to ensure it is at the recommended level. Low hydraulic fluid can lead to decreased performance, reduced lifting capacity, and potential overheating. If fluid levels are low, promptly replenish with the appropriate type of hydraulic fluid to maintain efficiency and prevent damage.

Cleaning

Keeping the HCYY11112010 clean is essential for its effective operation. Regularly clean the cylinder to remove debris, dirt, and contaminants that can interfere with its functionality. Use a damp cloth to wipe down surfaces, paying special attention to seals and joints to prevent dirt from entering the hydraulic system. A clean cylinder not only operates better but also extends its lifespan.

Professional Servicing

Scheduling periodic servicing by a qualified technician is crucial for comprehensive maintenance. A professional can perform in-depth inspections, troubleshoot any issues, and ensure that all components function correctly. This proactive approach helps identify potential problems before they escalate, ensuring the HCYY11112010 maintains peak performance and reliability throughout its service life. Regular professional checks also provide peace of mind, knowing that the equipment meets safety standards and operational guidelines.

How Often Should You Conduct Inspections On The HCYY11112010 Main Boom Angle Cylinder?

To guarantee the optimal performance and safety of the HCYY11112010 Main Boom Angle Cylinder, establishing a routine inspection schedule is crucial. Aim to conduct thorough inspections at least once a month. However, if your cylinder is frequently used or operates in demanding conditions—such as extreme temperatures, heavy dust, or moisture—it’s wise to increase the frequency to weekly checks.

Regular inspections are your first line of defense in maintenance. They provide the opportunity to identify early signs of wear, hydraulic leaks, or damage before they escalate into more significant issues. This proactive approach not only saves you from potential costly repairs but also enhances the safety of your aerial operations. Picture the peace of mind that comes from knowing your equipment is functioning flawlessly, ready to tackle any challenge with confidence.

Incorporating inspections into your routine not only ensures the HCYY11112010 remains in peak condition but also extends its lifespan, ultimately maximizing your investment. By committing to regular checks, you empower your team to work more efficiently and safely, allowing you to focus on what really matters—getting the job done right. Make inspections a priority, and watch your operational effectiveness soar!

Aerial Work Vehicles Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Prezrite si našu továreň na VR:

Vydajte sa na prehliadku našej továrne na VR

Ako funguje hydraulický valec vysokozdvižného vozíka?

Použitie hydraulického valca: