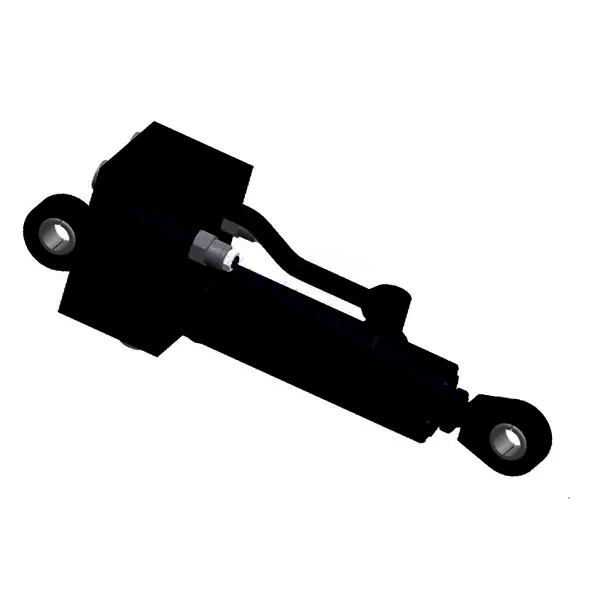

Ro-ro Platform Latch Cylinders (hydraulic self-locking)

Являясь одним из производителей, поставщиков и экспортеров механической продукции, мы предлагаем гидравлические цилиндры и многие другие изделия.

Пожалуйста, свяжитесь с нами для получения подробной информации.

Почта:sales@hydraulic-cylinders.net

Производитель поставщик экспортер гидроцилиндров.

Ro-ro Platform Latch Cylinders (hydraulic self-locking)

Ro-ro platform latch cylinders with hydraulic self-locking capabilities are essential components designed to enhance the safety and efficiency of roll-on/roll-off (ro-ro) operations. These innovative hydraulic cylinders provide a reliable and convenient locking mechanism to secure the platform during transportation, preventing unwanted movement and ensuring the safe delivery of goods. With their exceptional features and hydraulic self-locking mechanism, ro-ro platform latch cylinders are the ultimate solution for companies seeking enhanced security and streamlined logistics.

Ro-ro platform latch cylinders with hydraulic self-locking capabilities provide the utmost security and efficiency in ro-ro operations. With their hydraulic self-locking mechanism, robust construction, and easy integration, these cylinders ensure safe and streamlined transportation of goods. By following the recommended usage methods and implementing regular maintenance practices, companies can maximize the longevity and performance of these essential components, contributing to enhanced security and smooth logistics operations.

Ro-ro Platform Latch Cylinders (hydraulic self-locking) Key Characteristics:

- Hydraulic Self-Locking: Ro-ro platform latch cylinders feature a hydraulic self-locking mechanism that securely locks the platform once engaged. This eliminates the need for external locking devices, reducing complexity and increasing operational efficiency.

- Robust Construction: These cylinders are built with high-quality materials to withstand the demanding conditions of ro-ro operations. Their robust construction ensures durability and longevity, minimizing downtime and maintenance costs.

- Easy Integration: Ro-ro platform latch cylinders are designed for easy integration into existing ro-ro platform systems. They can be seamlessly installed and retrofitted, enabling quick and hassle-free implementation.

- Enhanced Safety: The hydraulic self-locking mechanism of these cylinders ensures that the platform remains securely locked during transportation. This feature significantly reduces the risk of accidents, preventing cargo shifts and enhancing overall safety.

Ro-ro Platform Latch Cylinders (hydraulic self-locking) Parameter:

| Product Name | Ro-ro Platform Latch Cylinder |

| Features: | Lock the bolt after the springboard or ramp is recovered in place |

| Specification: | Specifications: 80/50*S, 63/40*S, 40/28*S,front and rear Having DNVGL type approval With standard size series selection |

| Pressure | 25MPa (stainless steel piston rod) |

| Applications: | Ro-ro Platform |

Having DNVGL type approval

With standard size series selection

(stainless steel piston rod)

Ro-ro Platform Main Operating Cylinder Application:

Usage Method Of Ro-ro Platform Latch Cylinders (hydraulic self-locking):

- Installation: Ro-ro platform latch cylinders are installed strategically on the ro-ro platform. Mount the cylinders securely using appropriate brackets and hardware, ensuring proper alignment and clearance for operation.

- Activation: Once the platform is positioned and ready for transport, activate the hydraulic self-locking mechanism. This can be achieved through manual engagement or automated systems, depending on the specific design and requirements.

- Locking Verification: After engaging the self-locking mechanism, verify that the cylinders are securely locked and holding the platform. Perform visual inspections and functional tests to ensure proper engagement and functionality.

How Do Rephasing Hydraulic Cylinders Work?

The basic principle behind rephasing hydraulic cylinders is using interconnected fluid lines that allow for transferring hydraulic fluid between the cylinders. This interconnection enables the cylinders to share the load and maintain equal stroke lengths, regardless of variations in the bag or resistance encountered by each cylinder.

Here’s a step-by-step breakdown of how rephasing hydraulic cylinders works:

- Interconnected Fluid Lines: Rephasing cylinders are connected through fluid lines or passages. These lines allow hydraulic fluid to flow between the cylinders, creating a shared hydraulic system.

- Initial Positioning: The cylinders are initially positioned at the same starting point. This ensures they have the same starting stroke length and are ready to move in unison.

- Hydraulic Fluid Transfer: As hydraulic fluid is pumped into the system, it flows through the interconnected lines. The fluid pressure causes the cylinders to extend, and the liquid is distributed between the cylinders, maintaining equal pressure throughout the system.

- Load Distribution: When a load is applied to the rephasing cylinders, each cylinder experiences different resistance levels or forces. The cylinders with less resistance will extend further, while those with more resistance will extend less. This difference in extension causes the hydraulic fluid to flow from the more extended cylinder to the less comprehensive cylinder through the interconnected lines.

- Equalizing Stroke Lengths: The stroke lengths begin to equalize as the hydraulic fluid transfers between the cylinders. The cylinders adjust their extension levels until the load is distributed evenly, resulting in synchronized movement and equal stroke lengths.

- Balanced Force: Once the stroke lengths are equalized, the rephasing cylinders exert equal force on the load. This ensures balanced force distribution and prevents uneven loading or tilting of the system.

- Simultaneous Retraction: When the hydraulic system is reversed, or the cylinders need to retract, the fluid flow is reversed. The fluid is transferred back to the retracting cylinders, ensuring synchronized retraction and equal stroke lengths.

Возможности и мощности завода:

(1) Сборка

Мы располагаем первоклассной независимой сборочной платформой для проведения исследований и разработок. Цех по производству гидравлических цилиндров имеет четыре полуавтоматические линии сборки подъемных цилиндров и одну автоматическую линию сборки цилиндров наклона с проектной годовой производственной мощностью 1 млн. штук. Цех по производству специальных цилиндров оснащен полуавтоматической очистной сборочной системой различных спецификаций с проектной годовой производственной мощностью 200 тыс. штук и оснащен известным обрабатывающим оборудованием с ЧПУ, обрабатывающим центром, высокоточным специальным оборудованием для обработки цилиндров, роботом-сварщиком, автоматической очистной машиной, автоматической сборочной машиной цилиндров и автоматической покрасочной производственной линией. Существующее критически важное оборудование насчитывает более 300 комплектов (комплектов). Оптимальное распределение и эффективное использование ресурсов оборудования позволяет обеспечить требования к точности изделий и удовлетворить потребности в высоком качестве продукции.

(2) Механическая обработка

Цех оснащен специализированным токарным центром с наклонной направляющей, обрабатывающим центром, высокоскоростным хонинговальным станком, сварочным роботом и другим сопутствующим оборудованием, которое позволяет обрабатывать цилиндрические трубы с максимальным внутренним диаметром 400 мм и максимальной длиной 6 м.

(3) Сварка

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: