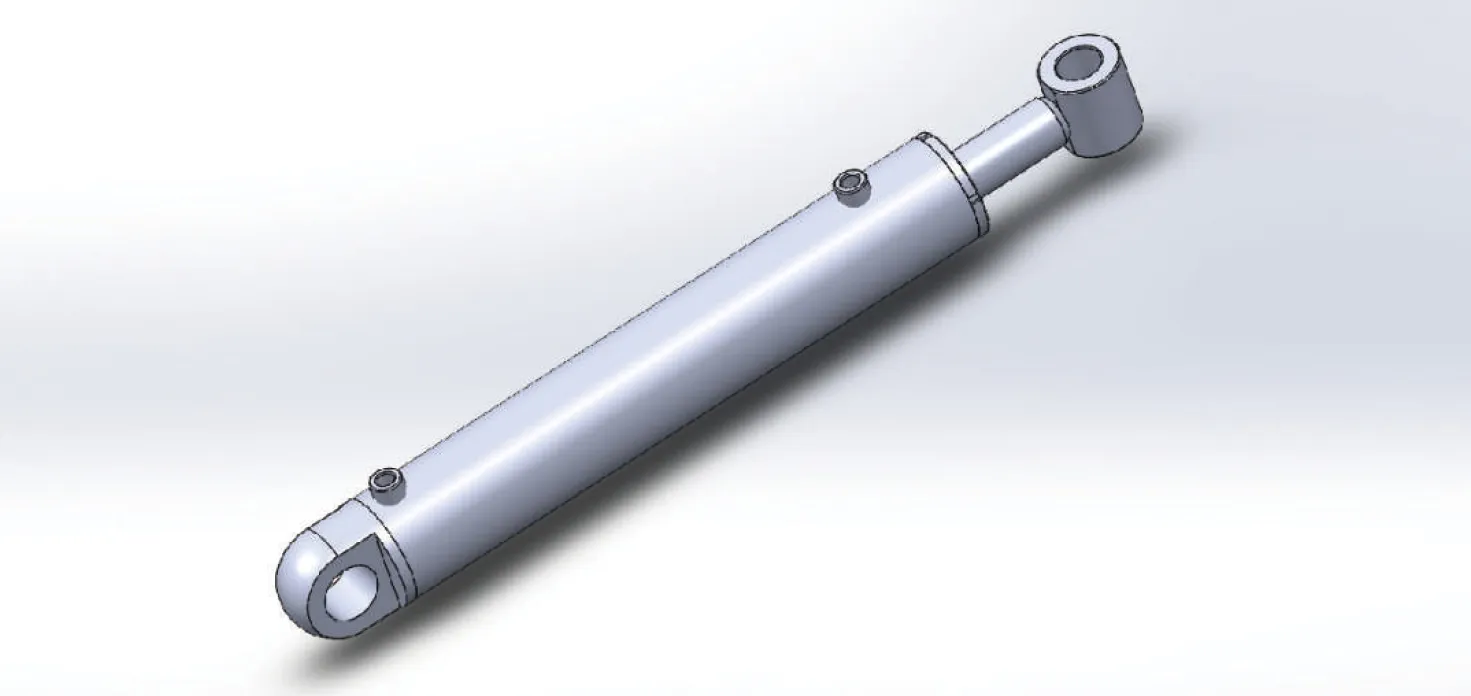

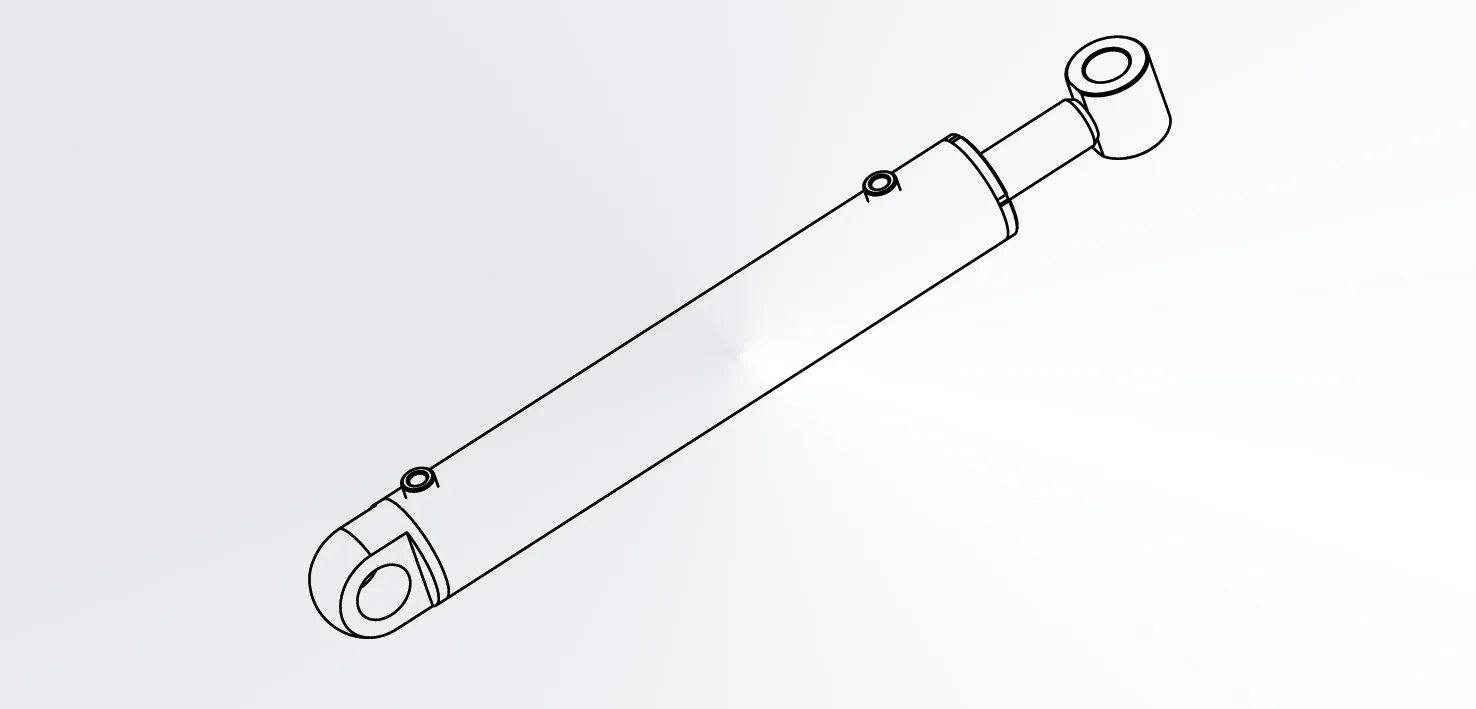

HCYY11112012 Steering Cylinder For Aerial Work Vehicles

Являясь одним из производителей, поставщиков и экспортеров механической продукции, мы предлагаем гидравлические цилиндры и многие другие изделия.

Пожалуйста, свяжитесь с нами для получения подробной информации.

Почта:sales@hydraulic-cylinders.net

Производитель поставщик экспортер гидроцилиндров.

HCYY11112012 Steering Cylinder For Aerial Work Vehicles

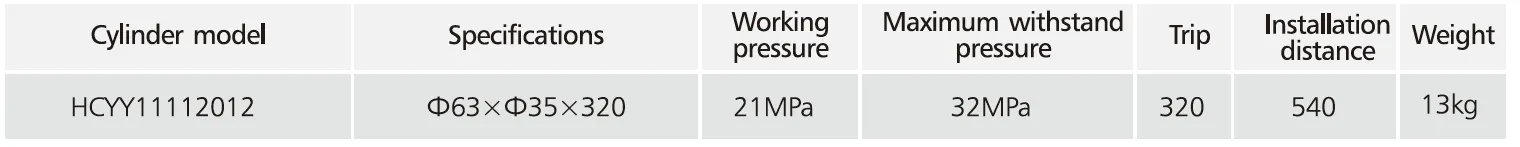

HCYY11112012 Steering Cylinder For Aerial Work Vehicles Parameter:

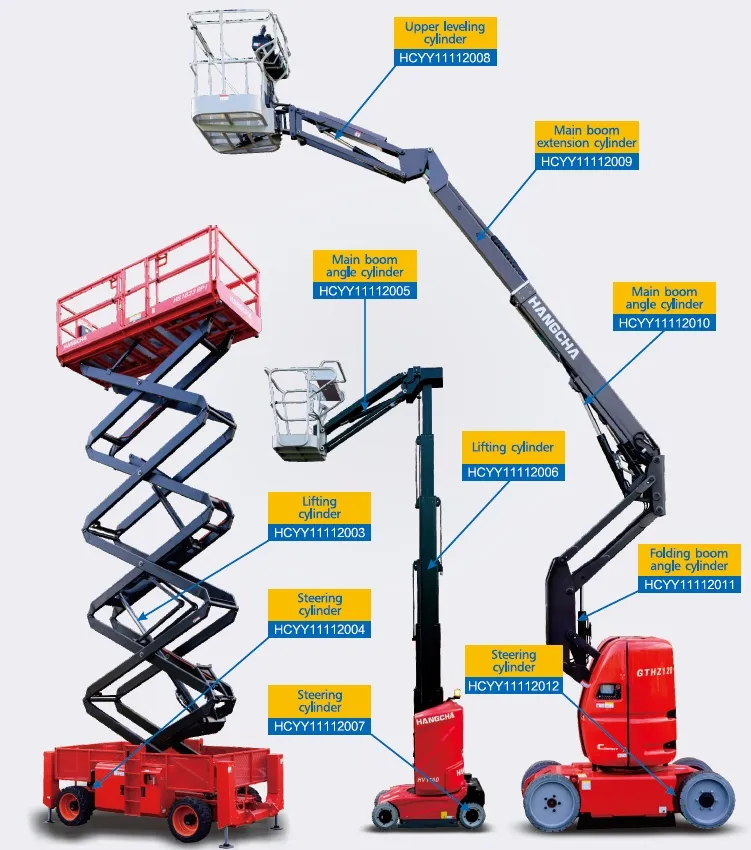

Cylinder Series For Aerial Work Vehicles:

Key Features of HCYY11112012 Steering Cylinder For Aerial Work Vehicles:

Robust Construction

The HCYY11112012 Steering Cylinder is engineered from premium-grade materials, ensuring exceptional durability under challenging conditions. Its heavy-duty design withstands extreme temperatures, heavy loads, and abrasive environments without compromising performance. This robust construction minimizes wear and tear, significantly reducing the frequency of replacements. Businesses benefit from lower operational costs and enhanced reliability, making this cylinder a smart investment for long-term use.

Enhanced Precision Control

Precision is vital in aerial operations, and the HCYY11112012 delivers exceptional steering accuracy. This steering cylinder allows for seamless and precise adjustments, enabling operators to position their vehicles with confidence. Whether navigating tight spaces or executing delicate aerial maneuvers, the cylinder’s responsiveness reduces the risk of errors. This accuracy not only enhances safety but also boosts overall efficiency, allowing teams to complete tasks more effectively.

Space-Saving Design

The HCYY11112012 boasts an innovative compact design that promotes easy installation and storage. Its space-saving features allow it to fit into tight compartments, making it particularly advantageous for mobile operations where space is often at a premium. When not in use, the cylinder folds neatly, facilitating efficient storage and transportation. This design ensures that operators can maximize their workspace and keep their equipment organized.

Impressive Load-Bearing Capacity

Designed for heavy-duty applications, the HCYY11112012 supports a remarkable load-bearing capacity. Its robust engineering ensures reliable performance even under substantial weight, making it ideal for tasks that involve lifting heavy equipment or materials. This impressive strength instills confidence in operators, as they can rely on the cylinder to perform effectively under pressure, ensuring safety and stability during critical operations.

Superior Corrosion Resistance

The HCYY11112012 incorporates advanced protective coatings that safeguard against rust and corrosion. This feature is crucial for extending the operational lifespan of the cylinder, especially in harsh weather conditions. The specialized coatings provide an additional layer of protection against rain, snow, and UV exposure, significantly reducing maintenance costs over time. Operators can focus on their tasks without worrying about frequent repairs or replacements due to environmental wear.

Easy Installation

Designed with versatility in mind, the HCYY11112012 is compatible with a wide range of aerial work vehicles. Its user-friendly installation process allows operators to set it up quickly and efficiently, often without the need for extensive training. This ease of installation minimizes downtime, enabling businesses to adapt their equipment swiftly to meet various operational requirements. The straightforward integration ensures that teams can get back to work promptly, maximizing productivity.

The HCYY11112012 Steering Cylinder stands out as a vital component for aerial work vehicles, offering a combination of durability, precision, and efficiency. Its robust construction, enhanced control capabilities, and space-saving design make it an ideal choice for operators seeking reliability and performance. By investing in the HCYY11112012, businesses can enhance their operational capabilities, ensuring safer and more efficient aerial work.

How Does The Precision Control Of The HCYY11112012 Enhance Your Aerial Work Tasks?

Certainly! Here’s an expanded and optimized version of each point regarding how the precision control of the HCYY11112012 enhances aerial work tasks:

Accurate Positioning

The HCYY11112012 Steering Cylinder provides operators with the ability to make fine adjustments, ensuring that the vehicle is positioned with pinpoint accuracy. This capability is crucial when working at heights or in tight spaces where even minor miscalculations can lead to significant issues. By allowing operators to align their vehicles precisely with the work area, the cylinder minimizes the risk of errors, ensuring that tasks are executed as planned.

Improved Safety

Enhanced precision in steering translates directly to improved safety for both operators and crew members on the ground. With the ability to navigate with accuracy, operators can avoid obstacles and precarious situations, reducing the likelihood of accidents. This heightened safety awareness not only protects personnel but also safeguards equipment and materials, fostering a secure work environment where everyone can perform their duties confidently.

Increased Efficiency

The ability to make swift and precise steering adjustments streamlines operations considerably. Operators can react quickly to changing conditions or instructions, allowing for a more dynamic workflow. This efficiency means that tasks can be completed faster, reducing downtime and enhancing overall productivity. Teams can achieve more within their operational window, maximizing the use of their resources and time.

Better Handling

The responsive nature of the HCYY11112012’s steering control improves the handling of aerial work vehicles, especially in challenging terrains or confined spaces. Operators experience greater confidence while maneuvering, as the cylinder’s precision allows for smoother transitions and turns. This enhanced handling capability not only makes operations easier but also contributes to a more stable platform for any tasks being performed, such as lifting or positioning equipment.

Overall, the precision control of the HCYY11112012 Steering Cylinder significantly enhances aerial work tasks by promoting accuracy, safety, efficiency, and handling. This results in a more productive work environment, where operators can focus on their responsibilities with confidence and ease.

Aerial Work Vehicles Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: