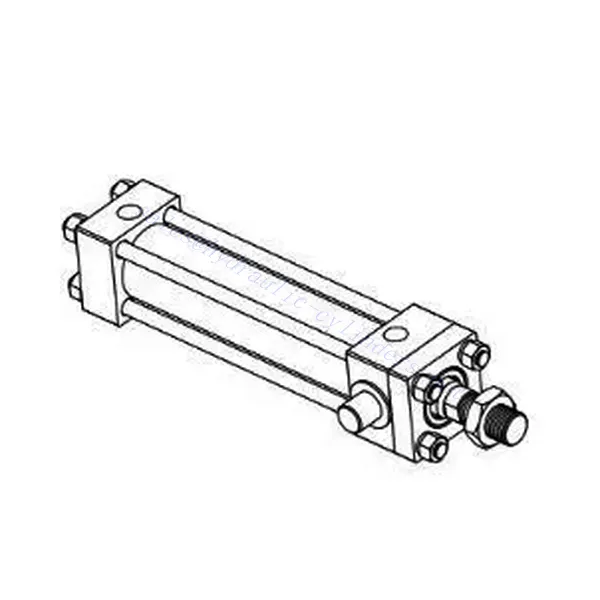

Cilindru hidraulic cu tijă grea de tip butuc frontal TA

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

Cilindru hidraulic cu tijă grea de tip butuc frontal TA

The TA front trunnion-type heavy rod hydraulic cylinder is a powerful and reliable hydraulic element that performs well in various industrial applications. With its robust construction, precise engineering, and advanced features, this hydraulic cylinder can stand out in demanding tasks that require force and precision. From heavy machinery to material handling equipment, TA front trunnion-type heavy rod hydraulic cylinders are designed to provide optimal power, control, and durability in various industrial environments.

Heavy Rod Hydraulic Cylinder Key Characteristics:

Robust Construction: TA front trunnion-type heavy rod hydraulic cylinders feature a full design with high-quality materials such as steel or alloys to withstand heavy loads, extreme pressures, and harsh operating conditions. Its rugged construction ensures long-lasting durability and resistance to wear, corrosion, and damage.

High Force Output: This heavy rod hydraulic cylinder is designed to provide superior force output, making it ideal for applications involving heavy lifting, pushing, or pulling. Its large piston diameter and high-pressure capability give it the strength to handle demanding tasks easily.

Precise Control: TA front trunnion type heavy rod hydraulic cylinder provides precise control over the movement and positioning of the load. Its advanced design combines precision machined components, high-quality seals, and smooth rod surfaces to ensure accurate and reliable operation.

Front Trunnion Mounting: The heavy rod hydraulic cylinder is designed with a front trunnion mounting system, which provides a safe and flexible mounting option. Front trunnion mounting allows easy integration into various hydraulic systems and equipment configurations.

TA Front Trunnion Type Heavy Rod Hydraulic Cylinder Parameter:

Cilindru hidraulic cu tijă grea de tip butuc frontal TA Usage Method:

Mounting: First, safely install the TA front trunnion-type heavy rod hydraulic cylinder into the designated position using the appropriate mounting brackets or fixtures. Ensure proper alignment and stability during installation to prevent cylinder misalignment or stress.

Hydraulic System Integration: Follow the manufacturer’s instructions and guidelines to connect hydraulic lines to cylinder ports. The cylinder is integrated into the hydraulic system by clicking it to a suitable pump or power unit. Ensure cylinder specifications and operating requirements are met.

Control and Operation: The control valve in the hydraulic system regulates the flow of hydraulic oil into and out of the cylinder. Adjust the control Settings according to the desired linear motion and force output. Test the movement of the cylinder to verify its function and responsiveness.

Cilindru hidraulic cu tijă grea de tip butuc frontal TA Maintenance:

Regular maintenance ensures optimal performance and service life of TA front trunnion-type heavy rod hydraulic cylinders. Here are some maintenance suggestions:

Regular Inspection: Perform routine inspections to identify any signs of wear, damage, or leaks. Check for abnormalities in cylinder blocks, piston rods, seals, and other components. Resolve any issues promptly to prevent further injury or operational inefficiencies.

Lubrication: Apply the recommended lubricant to the moving parts of the cylinder, including tie rods and seals. Regular lubrication minimizes friction, reduces wear, and ensures smooth operation. Use the appropriate lubricant type according to the manufacturer’s lubrication interval guidelines.

Seal Replacement: If seals are found to be deteriorating or leaking, replace seals with genuine parts approved by the manufacturer. Damaged or worn seals can compromise the cylinder’s performance and lead to hydraulic oil leakage.

Cleaning: Clean cylinders by removing dirt, debris, and other contaminants. Before reassembling, use a non-abrasive cleaner and make sure all parts are completely dry. Regular cleaning promotes optimal performance and prevents premature wear or damage.

How To Replace Seals In A Hydraulic Cylinder?

Replacing seals in a hydraulic cylinder requires careful attention and proper procedure to ensure successful replacement. Here’s a step-by-step guide on how to replace seals in a hydraulic cylinder:

- Safety Precautions: Before starting any maintenance work, take appropriate safety precautions. Ensure the hydraulic system is depressurized and the equipment is adequately supported and secured. Wear protective gloves and safety glasses to protect yourself from any potential hazards.

- Cylinder Removal: Depending on the specific hydraulic system and cylinder design, you may need to remove the hydraulic cylinder from its mounting location. Follow the manufacturer’s instructions or consult the equipment manual for the proper procedure to remove the cylinder.

- Cylinder Disassembly: Once the hydraulic cylinder is removed, carefully disassemble it to access the seals. Typically, hydraulic cylinders consist of a cylinder barrel, piston, piston rod, and various seals. Follow these steps:a. Remove the Cylinder Head: Unscrew or unbolt the cylinder head from the barrel, exposing the piston and piston rod.b. Remove the Piston: Gently slide the piston out of the cylinder barrel. Be cautious to avoid damaging the piston or the cylinder walls.c. Remove the Old Seals: Identify the seals that need to be replaced, such as piston seals, rod seals, or wiper seals. Use appropriate tools, such as seal removal picks or hooks, to remove the old seals from their grooves. Take note of the seal orientation for proper installation of the new seals.

- Seal Preparation: Inspect the new seals for any defects or damage before installing them. Ensure that you have the correct replacement seals that match the specifications of the original ones. Apply a thin film of hydraulic oil or seal lubricant to the new seals to facilitate proper installation and reduce friction.

- Seal Installation:a. Piston Seals: Start by installing the new piston seals. Carefully position the seals into their grooves, ensuring they sit flush and are not twisted. Use a seal installation tool or soft-faced mallet to press the seals into place gently. Ensure that the seals are evenly seated and properly aligned.b. Rod Seals and Wiper Seals: Move on to installing the rod and wiper seals. Again, position the seals correctly in their grooves, ensuring they are not twisted. Apply gentle pressure using a seal installation tool or a mallet to secure the seals.

- Reasamblare: Once all the new seals are installed, reassemble the hydraulic cylinder. Follow these steps:a. Reinstall the Piston: Carefully slide the piston back into the cylinder barrel, ensuring it moves freely without any obstruction. Align any retention mechanisms, such as snap rings or circlips, as necessary.b. Reattach the Cylinder Head: Place the cylinder head back onto the cylinder barrel and secure it with screws or bolts. Ensure proper tightening according to the manufacturer’s specifications.

- Cylinder Installation: If you removed the hydraulic cylinder from its mounting location, reinstall it following the appropriate procedure. Ensure proper alignment and connection to the hydraulic system, including the lines and fittings.

- Testing and Inspection: Test its functionality once the hydraulic cylinder is reinstalled. Gradually pressurize the system and check for any leaks, abnormal noises, or improper operation. Conduct a thorough inspection to ensure the seals are performing as intended.

Capabilitatea și capacitatea fabricii:

(1) Montaj

Avem o platformă de asamblare independentă de cercetare și dezvoltare de primă clasă. Atelierul de producție a cilindrilor hidraulici are patru linii de asamblare semiautomate pentru cilindri de ridicare și o linie de asamblare automată a cilindrilor de înclinare, cu o capacitate de producție anuală proiectată de 1 milion de bucăți. Atelierul de cilindri speciali este echipat cu diverse specificații ale unui sistem de asamblare semi-automat de curățare, cu o capacitate de producție anuală proiectată de 200.000 și dotat cu echipamente celebre de prelucrare CNC, un centru de prelucrare, un echipament special de prelucrare a cilindrilor de înaltă precizie, o mașină de sudură robotizată, o mașină de curățare automată, o mașină de asamblare automată a cilindrilor și o linie de producție automată de vopsire. Echipamente critice existente de peste 300 de seturi (seturi). Alocarea optimă și utilizarea eficientă a resurselor de echipamente asigură cerințele de precizie ale produselor și satisface nevoile de înaltă calitate ale produselor.

(2) Prelucrare

Atelierul de prelucrare este echipat cu un centru de strunjire cu șină înclinată personalizat, un centru de prelucrare, o mașină de honuire de mare viteză, un robot de sudură și alte echipamente conexe, care pot gestiona prelucrarea tuburilor cilindrice cu un diametru interior maxim de 400 mm și o lungime maximă de 6 metri.

(3) Sudură

(4) Vopsire și acoperire

Cu linii automate de acoperire cu vopsea pe bază de apă cu cilindru de dimensiuni mici și medii, pentru a realiza încărcarea și descărcarea automată a robotului și pulverizarea automată, capacitatea de proiectare de 4000 de bucăți pe schimb;

Avem, de asemenea, o linie de producție semi-automată de vopsire pentru cilindri mari, acționată de un lanț de putere, cu o capacitate de proiectare de 60 de cutii pe schimb.

(5) Testarea

Dispunem de instalații de inspecție și bancuri de testare de primă clasă pentru a ne asigura că performanța cilindrului îndeplinește cerințele.

We are one of the best heavy rod hydraulic cylinder manufacturers. We can offer wide heavy rod hydraulic cylinder stock. We also provide corresponding cutii de viteze agricole. Am exportat produsele noastre către clienți din întreaga lume și am câștigat o bună reputație datorită calității superioare a produselor noastre și a serviciilor post-vânzare. Salutăm călduros clienții atât din țară, cât și din străinătate să ne contacteze pentru a negocia afaceri, a face schimb de informații și a să coopereze cu noi!

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cum funcționează cilindrul hidraulic pentru stivuitor?

Cilindru hidraulic Aplicație: