Mobile Crane Suspension Cylinder

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

Mobile Crane Suspension Cylinder

The mobile crane suspension cylinder is vital in mobile crane systems and is designed to optimize stability and performance during lifting operations. This hydraulic cylinder supports the crane’s suspension system, ensuring smooth and controlled movement while carrying heavy loads.

The mobile crane suspension cylinder is an indispensable component for mobile crane systems, providing stability, load distribution, and height adjustability. With its robust construction, precise hydraulic control, improved suspension capabilities, and ease of operation, this hydraulic cylinder significantly enhances lifting operations’ overall performance and safety. By following proper usage methods and adhering to recommended maintenance practices; operators can maximize the lifespan and reliability of the Mobile Crane Suspension Cylinder, ensuring safe and efficient lifting in various construction and industrial settings. Choose this essential hydraulic component to elevate your mobile crane system’s stability, performance, and versatility, enabling successful operations and achieving new heights of productivity.

Mobile Crane Suspension Cylinder Key Characteristics:

- Robust Construction:

- The Mobile Crane Suspension Cylinder is built with high-quality materials, ensuring durability and reliability in demanding working conditions.

- It is designed to withstand heavy loads, shocks, and vibrations, providing long-lasting performance even in challenging environments.

- Control hidraulic:

- This cylinder utilizes hydraulic power to control the suspension system of the mobile crane.

- The hydraulic control allows for precise adjustments, ensuring optimal stability and load distribution during lifting operations.

- Improved Suspension:

- The crane’s suspension system achieves enhanced stability and load-bearing capacity by incorporating the mobile crane suspension cylinder.

- It effectively absorbs shocks and vibrations, minimizing the impact on the crane’s structure and ensuring smoother operation.

- Height Adjustment:

- The suspension cylinder enables the adjustment of the crane’s height, allowing operators to adapt to various job site conditions.

- Height adjustability enhances flexibility, enabling the crane to work efficiently in areas with limited overhead clearance or uneven terrain.

Mobile Crane Suspension Cylinder Parameter:

| Product Name | Mobile Crane Suspension Cylinder |

| Features: | Damping system for crane chassis |

| Bore diameter: | 85mm~180mm |

| Rod diameter: | 50mm~100mm Stroke≤300mm |

| Pressure: | Maximum 35MPa |

| Suspension Cylinder Applications: | Mobile Crane |

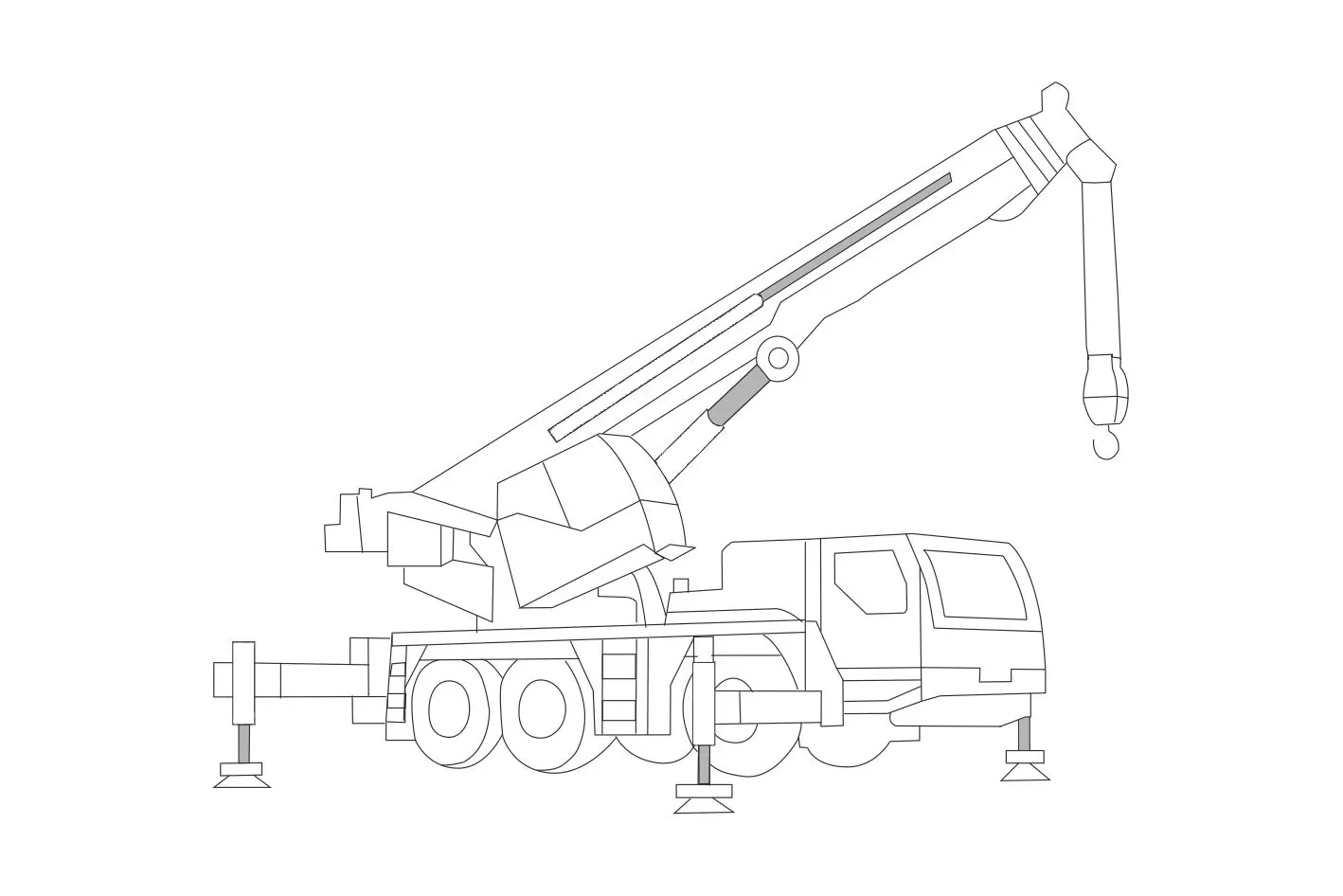

Mobile Crane Identification Diagram:

Usage Method Of Mobile Crane Suspension Cylinder:

- Familiarize with Controls:

- Before the operation, operators must familiarize themselves with the controls associated with the mobile crane suspension cylinder.

- Understand the control mechanisms and operating procedures specific to the crane model.

- Suspension Adjustment:

- Activate the hydraulic controls to adjust the suspension system according to the desired height or load requirements.

- Ensure the adjustment is performed gradually and smoothly to maintain stability throughout the process.

- Load Distribution:

- Monitor and assess the load distribution on the crane during operation.

- Adjust the suspension system as necessary to balance the load and maintain stability.

- Operating on Uneven Terrain:

- When working on uneven terrain, utilize the suspension cylinder to adjust the crane’s suspension and maintain a level platform.

- This ensures that the load remains stable and that the crane operates safely and efficiently.

How To Release Pressure On Hydraulic System?

To release pressure from a hydraulic system safely, follow these steps:

- Shut Down the System:

- Turn off any power sources or engines connected to the hydraulic system.

- This step ensures that no additional pressure is generated while you release the existing tension.

- Identify the Pressure Release Points:

- Locate the pressure release points in the hydraulic system.

- Common pressure release points include relief, pressure control, or directional control valves.

- Relieve Pressure at the Valve:

- If your system has a relief valve, start by locating it.

- Slowly turn the relief valve counterclockwise to release pressure.

- Monitor the pressure gauge, if available, to observe the pressure dropping.

- Use the Controls:

- If your system has directional control valves, move them to the neutral position.

- This action allows fluid to flow freely and relieves pressure in the system.

- Release Accumulator Pressure:

- If your hydraulic system has an accumulator, it may store pressure even when the system is shut down.

- Refer to the manufacturer’s instructions to release the pressure stored in the accumulator safely.

- Usually, this involves opening a specific valve or venting the accumulator to the atmosphere.

- Bleed the System:

- After releasing the pressure at the designated pressure release points, it is important to bleed the system to ensure no trapped pressure.

- Begin by opening any bleed screws or valves located in the hydraulic system.

- Slowly open them to allow any remaining pressure or air to escape.

- Be cautious and use appropriate personal protective equipment (PPE) to avoid contact with hydraulic fluid.

- Verify Pressure Release:

- Double-check that the pressure has been fully released from the hydraulic system.

- If available, use a pressure gauge or other monitoring devices to ensure the pressure is at or near zero.

Capabilitatea și capacitatea fabricii:

(1) Montaj

Avem o platformă de asamblare independentă de cercetare și dezvoltare de primă clasă. Atelierul de producție a cilindrilor hidraulici are patru linii de asamblare semiautomate pentru cilindri de ridicare și o linie de asamblare automată a cilindrilor de înclinare, cu o capacitate de producție anuală proiectată de 1 milion de bucăți. Atelierul de cilindri speciali este echipat cu diverse specificații ale unui sistem de asamblare semi-automat de curățare, cu o capacitate de producție anuală proiectată de 200.000 și dotat cu echipamente celebre de prelucrare CNC, un centru de prelucrare, un echipament special de prelucrare a cilindrilor de înaltă precizie, o mașină de sudură robotizată, o mașină de curățare automată, o mașină de asamblare automată a cilindrilor și o linie de producție automată de vopsire. Echipamente critice existente de peste 300 de seturi (seturi). Alocarea optimă și utilizarea eficientă a resurselor de echipamente asigură cerințele de precizie ale produselor și satisface nevoile de înaltă calitate ale produselor.

(2) Prelucrare

Atelierul de prelucrare este echipat cu un centru de strunjire cu șină înclinată personalizat, un centru de prelucrare, o mașină de honuire de mare viteză, un robot de sudură și alte echipamente conexe, care pot gestiona prelucrarea tuburilor cilindrice cu un diametru interior maxim de 400 mm și o lungime maximă de 6 metri.

(3) Sudură

(4) Vopsire și acoperire

Cu linii automate de acoperire cu vopsea pe bază de apă cu cilindru de dimensiuni mici și medii, pentru a realiza încărcarea și descărcarea automată a robotului și pulverizarea automată, capacitatea de proiectare de 4000 de bucăți pe schimb;

Avem, de asemenea, o linie de producție semi-automată de vopsire pentru cilindri mari, acționată de un lanț de putere, cu o capacitate de proiectare de 60 de cutii pe schimb.

(5) Testarea

Dispunem de instalații de inspecție și bancuri de testare de primă clasă pentru a ne asigura că performanța cilindrului îndeplinește cerințele.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding cutii de viteze agricole. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and să coopereze cu noi!

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cum funcționează cilindrul hidraulic pentru stivuitor?

Cilindru hidraulic Aplicație: