Jack-up Platform Bolt Offshore Hydraulic Cylinder

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

Jack-up Platform Bolt Offshore Hydraulic Cylinder

The jack-up platform bolt offshore hydraulic cylinder is a cutting-edge hydraulic component engineered for reliable and efficient support of offshore platforms. This innovative cylinder is crucial in elevating and stabilizing platforms, ensuring safe and productive operations in challenging offshore environments. With its exceptional features and robust construction, the jack-up platform bolt offshore hydraulic cylinder offers the ultimate solution for the offshore industry worldwide.

Designed for maximum reliability and efficiency, the jack-up platform bolt offshore hydraulic cylinder effectively elevates and stabilizes offshore platforms. Its sturdy design, enhanced stability, and adjustable elevation capabilities ensure seamless operations in demanding conditions. By adhering to recommended usage methods and implementing regular maintenance practices, operators can significantly extend the lifespan and performance of this vital component, ultimately contributing to the success of offshore projects.

Choose the jack-up platform bolt offshore hydraulic cylinder for unparalleled support and stability in your offshore operations, and experience the difference it can make in enhancing safety and productivity.

Jack-up Platform Bolt Offshore Hydraulic Cylinder Parameter:

| Product Name | Jack-up Platform Bolt Offshore Hydraulic Cylinder |

| Features: | Insert and pull out the cylindrical pin on the ring beam to realize the locking of the ring beam |

| Bore diameter: | Up to 100mm |

| Rod diameter: | Up to 60mm |

| Pressure: | Up to 32Mpa |

| Sensor: | It can be equipped with a built-in displacement sensor device to reduce the installation size of the hydraulic cylinders |

| Applications: | Jack-up Offshore Platform |

Rod diameter: up to 60mm

Jack-up Platform Bolt Offshore Hydraulic Cylinder Key Characteristics:

Robust Construction

The jack-up platform bolt offshore hydraulic cylinder is engineered to endure the harshest offshore conditions. Made from high-quality, corrosion-resistant materials, it offers exceptional durability and longevity, significantly reducing maintenance needs.

Enhanced Stability

This hydraulic cylinder is designed to provide superior stability for offshore platforms during elevation. Its strong bolt mechanism ensures a secure connection between the platform and its supporting structure, minimizing movement and maximizing safety throughout operations.

Hydraulic Power

Powered by a sophisticated hydraulic system, the jack-up platform bolt offshore hydraulic cylinder uses pressurized fluids to generate the force necessary for platform elevation. This hydraulic mechanism allows for precise control during the elevation process, ensuring smooth and controlled movements.

Adjustable Elevation

The jack-up platform bolt cylinder features adjustable height capabilities, allowing it to adapt to varying water depths and sea conditions. This flexibility ensures optimal platform positioning, enhancing stability and facilitating efficient operations.

Choose the jack-up platform bolt offshore hydraulic cylinder for unparalleled performance and reliability in your offshore projects. Experience enhanced safety and efficiency with this essential component.

How To Repair A Hydraulic Cylinder?

Repairing a hydraulic cylinder requires careful attention to detail and adherence to safety procedures. Here’s a step-by-step guide on how to repair a hydraulic cylinder:

1. Safety First

Before beginning any repair work, ensure that the hydraulic system is depressurized and the cylinder is securely supported. Wear appropriate personal protective equipment (PPE) such as gloves and safety glasses to protect yourself from potential hazards.

2. Identify the Problem

Assess the hydraulic cylinder to determine the specific issue that needs to be addressed. Common problems include leaks, damaged seals, scoring on the piston rod, or bent components. Understanding the problem will help you determine the necessary repair steps and parts.

3. Gather Tools and Replacement Parts

Prepare the required tools and replacement parts before starting the repair. Typical devices include wrenches, pliers, a mallet or hammer, seal removal tools, and a hydraulic press. Ensure your hydraulic cylinder model has the correct replacement seals, O-rings, and other components.

4. Disassemble the Cylinder:

Carefully disassemble the hydraulic cylinder, following the manufacturer’s instructions. Take note of the order in which components are removed, as this will guide the reassembly process. Keep track of shims or spacers, as they may need reinstalling in the same position.

5. Inspect and Clean Components:

Inspect all disassembled components for signs of wear, damage, or scoring. Clean the parts using a suitable cleaning agent to remove dirt, debris, and old lubricant. Ensure all surfaces are clean and free of contaminants before proceeding.

6. Replace Seals and O-rings:

Replace any worn or damaged seals, O-rings, or gaskets. Apply a thin layer of hydraulic fluid to lubricate the seals before installation. Ensure proper alignment and fit of the new seals to prevent leaks.

7. Repair or Replace Damaged Parts:

If any components, such as the piston rod or cylinder barrel, are damaged beyond repair, they may need to be replaced. Follow the manufacturer’s guidelines for proper replacement procedures. Use a hydraulic press if necessary to ensure accurate and precise assembly.

8. Reassemble the Cylinder:

Reassemble the hydraulic cylinder in reverse order for disassembly. Ensure that all components are correctly aligned and fitted. Use a torque wrench to tighten bolts and fasteners to the manufacturer’s specifications. Pay attention to proper orientation and alignment of components.

9. Test for Leaks:

Once reassembled, test the hydraulic cylinder for leaks. Apply hydraulic pressure to the system and inspect for any signs of leakage around seals or connections. If leaks are detected, address them by adjusting or replacing the affected components.

10. Functionality and Operation Testing:

Test the repaired hydraulic cylinder for proper functionality and operation. Verify that the cylinder moves smoothly and performs as expected. Monitor for any abnormal sounds or movements during the operation.

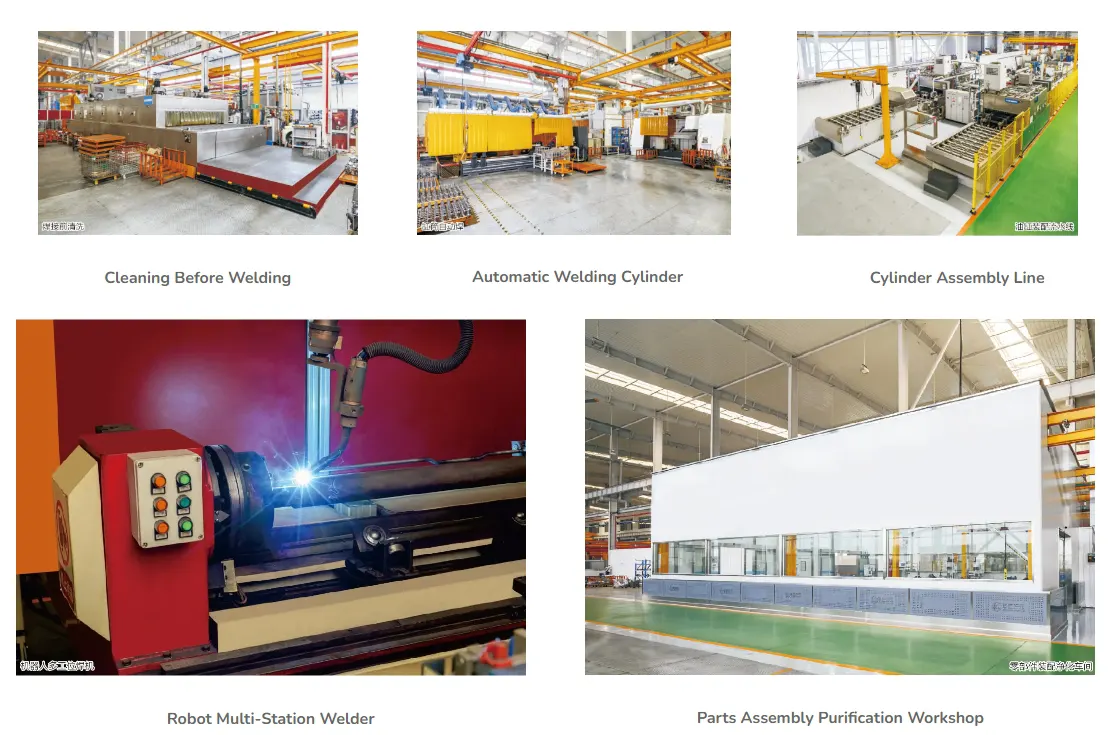

Capabilitatea și capacitatea fabricii:

(1) Montaj

Our facility boasts a top-tier independent research and development assembly platform dedicated to hydraulic cylinder production. We operate four semi-automatic lifting cylinder assembly lines and one fully automatic tilt cylinder assembly line, with an impressive annual production capacity of 1 million cylinders.

In our specialized cylinder workshop, we utilize a semi-automatic cleaning assembly system designed for various specifications, capable of producing 200,000 cylinders annually. Our workshop is equipped with advanced CNC machining equipment, a machining center, high-precision cylinder processing tools, robot welding machines, automatic cleaning systems, and an automated cylinder assembly line. Additionally, we have a fully automated painting production line.

With over 300 pieces of critical equipment, our optimal resource allocation ensures that we meet the strict accuracy and quality standards required by our clients. This commitment to efficiency and precision positions us as a leader in the hydraulic cylinder industry.

(2) Prelucrare

Our machining shop features state-of-the-art equipment, including a customized inclined rail turning center, a precision machining center, a high-speed honing machine, and advanced welding robots. This sophisticated setup enables us to efficiently process cylinder tubes with a maximum inner diameter of 400mm and a length of up to 6 meters.

With our cutting-edge technology, we ensure high-quality machining that meets the diverse needs of hydraulic cylinder production.

(3) Sudură

(4) Painting & Coating

Our facility features advanced automatic water-based paint coating lines specifically designed for small and medium-sized cylinders. These lines utilize robotic technology for efficient loading, unloading, and spraying, achieving a remarkable production capacity of 4,000 pieces per shift.

In addition, we operate a semi-automatic paint production line for large cylinders, powered by a robust power chain, with a designed capacity of 60 cases per shift. This combination of automation and efficiency ensures high-quality finishes for all our hydraulic cylinders.

(5) Testarea

Dispunem de instalații de inspecție și bancuri de testare de primă clasă pentru a ne asigura că performanța cilindrului îndeplinește cerințele.

We are a renowned manufacturer of cilindri hidraulici, recognized as one of the best in the industry. Our extensive product line includes a wide range of hydraulic cylinders tailored to meet various applications. In addition to hydraulic cylinders, we also provide high-quality agricultural gearboxes, ensuring our customers have access to comprehensive solutions for their machinery needs.

With a commitment to excellence, we have successfully exported our products to clients worldwide, earning a strong reputation for superior product quality and exceptional after-sales service. Our dedication to customer satisfaction has positioned us as a trusted partner in both domestic and international markets.

Why Choose Us?

Professional Expertise: Our team comprises industry professionals with extensive knowledge and experience in hydraulic systems, ensuring that we deliver top-notch products and services.

International Certifications: We adhere to strict quality standards and hold various international certifications, demonstrating our commitment to delivering reliable and safe hydraulic solutions.

Custom Solutions: We understand that each customer’s needs are unique. That’s why we offer customized hydraulic cylinders and gearboxes tailored to meet specific requirements.

Advanced Production Equipment: Our state-of-the-art manufacturing facilities utilize the latest technology and equipment, enabling us to produce high-quality products efficiently.

Comprehensive After-Sales Support: Our commitment to our customers extends beyond the sale. We provide ongoing support and maintenance services to ensure optimal performance of our products.

We invite customers from around the globe to reach out to us for business negotiations, information exchange, and collaboration opportunities. Together, we can achieve greater success in the hydraulic industry!

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding cutii de viteze agricole. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and să coopereze cu noi!

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cum funcționează cilindrul hidraulic pentru stivuitor?

Cilindru hidraulic Aplicație: