Metoda capului Orhideea tip Orchid cilindru hidraulic metalurgic Metalurgic

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

Metoda capului Orhideea tip Orchid cilindru hidraulic metalurgic Metalurgic

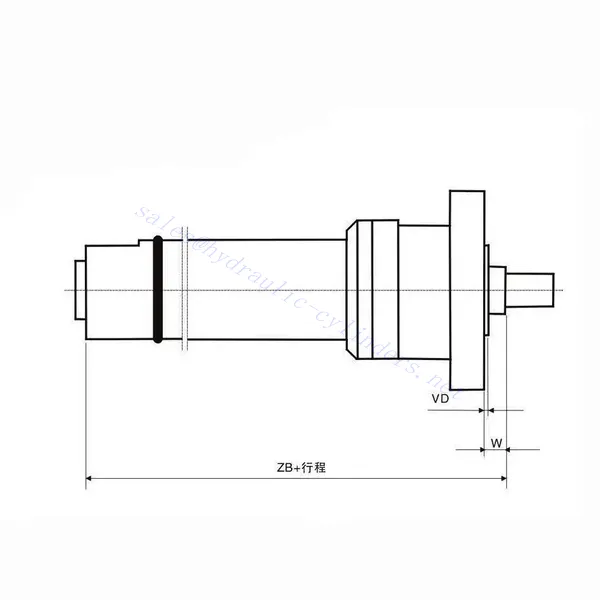

The head method orchid-type metallurgical hydraulic cylinder is a versatile, high-performance component explicitly designed for metallurgical applications. The product provides superior functionality, precise control, and reliable operation in demanding industrial environments. Its head method of orchid design ensures optimum performance, stability, and safety in the process.

The hydraulic cylinder of Y-HG1 series metallurgical equipment is a double-acting piston cylinder; the cylinder diameter is generally within the range of 40~320mm, and the working pressure is <=16MPA. The hydraulic oil system can transport the active medium, such as emulsion, and install different models, such as flanges, earrings, pins, and release devices (base).

High precision CNC honing machine, automatic welding machine, vertical, horizontal machining center, gantry machining center, CNC lathe, and other processing equipment, product quality is stable and guaranteed.

Head Method Orchid Type Metallurgical Hydraulic Cylinder Parameter:

Metoda capului Orhideea tip Orchid cilindru hidraulic metalurgic Metalurgic Usage Method:

- Mounting and Installation:

- Determine the appropriate installation position of the hydraulic cylinder according to the specific metallurgical application and equipment requirements.

- Ensure the mounting surface is clean, flat, and can withstand the cylinder load.

- Connection to Hydraulic System:

- Connect the metallurgical hydraulic cylinder to the hydraulic system using a compatible hydraulic hose or pipe.

- Ensure proper alignment and secure connection to prevent leakage.

- System Integration and Calibration:

- According to the manufacturer’s guidelines, integrate metallurgical hydraulic cylinders into metallurgical equipment or systems.

- Calibrate the system to achieve desired performance and operating parameters.

- Operating the Cylinder:

- Start the hydraulic system. Apply pressure to start the movement of the hydraulic cylinder.

- Control the cylinder’s extension, retraction, and positioning through the hydraulic control system.

Metoda capului Orhideea tip Orchid cilindru hidraulic metalurgic Metalurgic Maintenance:

- Inspecție periodică:

- Conduct routine inspections of the metallurgical hydraulic cylinder to check for leaks, signs of wear, or damage.

- Inspect the mounting brackets, fasteners, and connections to ensure they are secure and functioning correctly.

- Lubrifiere:

- Follow the manufacturer’s recommendations regarding lubrication intervals and the type of lubricant to use

- Apply lubricant to the necessary parts, such as the piston rod, seals, and bearings, to reduce friction and ensure smooth operation.

- Cleaning:

- Keep metallurgical hydraulic cylinders and their surrounding areas clean from dirt, debris, and contaminants that may affect their performance.

- Use appropriate cleaning methods and materials to avoid damaging the cylinder or its components.

How To Replace Hydraulic Cylinder Seals?

Replacing hydraulic cylinder seals requires careful attention to detail and adherence to proper procedures. Here’s a step-by-step guide to help you with the process:

- Gather the Necessary Tools and Materials:

- New seals for the hydraulic cylinder.

- Seal installation tool kit (if available).

- Clean rags or towels.

- Proper personal protective equipment, such as gloves and safety glasses.

- Prepare the Work Area:

- Ensure you have a clean and well-lit workspace to perform the seal replacement.

- Clean the exterior of the hydraulic cylinder to prevent dirt and debris from entering during the process.

- Depressurize the Hydraulic System:

- Shut off the hydraulic power source and relieve the pressure from the system.

- Follow the manufacturer’s instructions or consult the equipment manual for the proper depressurization procedure.

- Remove the Cylinder:

- Disconnect any hydraulic hoses or fittings attached to the cylinder.

- Unfasten the mounting bolts or brackets securing the cylinder to the equipment.

- Carefully remove the cylinder from its mounting location.

- Disassemble the Cylinder:

- If necessary, remove any external components or accessories attached to the cylinder, such as rod end caps or piston heads.

- Inspect and clean the cylinder thoroughly to remove any dirt or contaminants.

- Remove the Old Seals:

- Identify the location of the seals on the cylinder.

- Use an appropriate tool, such as a seal pick or seal removal tool, to carefully pry out the old seals.

- Take note of the seal orientation and arrangement for properly installing the new seals.

- Clean and Inspect:

- Clean the seal grooves and the surrounding areas using a lint-free cloth or rag.

- Inspect the cylinder bore and other components for any signs of damage or wear.

- If any damage is detected, consult a professional or replace the damaged components.

- Install the New Seals:

- Apply a thin layer of hydraulic oil or lubricant to the new seals to aid their installation.

- Carefully place the new seals into their grooves, ensuring they are appropriately seated and aligned correctly.

- Use a seal installation or suitable tool with a flat, smooth surface to gently press the seals into place.

- Take care not to damage or distort the seals during the installation process.

- Reassemble and Reinstall the Cylinder:

- Reassemble any disassembled components or accessories onto the cylinder.

- Reinstall the cylinder into its mounting location, ensuring proper alignment and secure fastening.

- Reconnect the hydraulic hoses or fittings, ensuring they are correctly tightened and secured.

- Test and Inspect:

- Restore the hydraulic system’s power and pressurize it according to the manufacturer’s instructions.

- Test the cylinder’s operation and check for any signs of leaks or abnormal behavior.

- If any issues are detected, troubleshoot or consult a professional for further assistance.

Capabilitatea și capacitatea fabricii:

(1) Montaj

Avem o platformă de asamblare independentă de cercetare și dezvoltare de primă clasă. Atelierul de producție a cilindrilor hidraulici are patru linii de asamblare semiautomate pentru cilindri de ridicare și o linie de asamblare automată a cilindrilor de înclinare, cu o capacitate de producție anuală proiectată de 1 milion de bucăți. Atelierul de cilindri speciali este echipat cu diverse specificații ale unui sistem de asamblare semi-automat de curățare, cu o capacitate de producție anuală proiectată de 200.000 și dotat cu echipamente celebre de prelucrare CNC, un centru de prelucrare, un echipament special de prelucrare a cilindrilor de înaltă precizie, o mașină de sudură robotizată, o mașină de curățare automată, o mașină de asamblare automată a cilindrilor și o linie de producție automată de vopsire. Echipamente critice existente de peste 300 de seturi (seturi). Alocarea optimă și utilizarea eficientă a resurselor de echipamente asigură cerințele de precizie ale produselor și satisface nevoile de înaltă calitate ale produselor.

(2) Prelucrare

Atelierul de prelucrare este echipat cu un centru de strunjire cu șină înclinată personalizat, un centru de prelucrare, o mașină de honuire de mare viteză, un robot de sudură și alte echipamente conexe, care pot gestiona prelucrarea tuburilor cilindrice cu un diametru interior maxim de 400 mm și o lungime maximă de 6 metri.

(3) Sudură

(4) Vopsire și acoperire

Cu linii automate de acoperire cu vopsea pe bază de apă cu cilindru de dimensiuni mici și medii, pentru a realiza încărcarea și descărcarea automată a robotului și pulverizarea automată, capacitatea de proiectare de 4000 de bucăți pe schimb;

Avem, de asemenea, o linie de producție semi-automată de vopsire pentru cilindri mari, acționată de un lanț de putere, cu o capacitate de proiectare de 60 de cutii pe schimb.

(5) Testarea

Dispunem de instalații de inspecție și bancuri de testare de primă clasă pentru a ne asigura că performanța cilindrului îndeplinește cerințele.

We are one of the best metallurgical hydraulic cylinder manufacturers. We can offer comprehensive metallurgical hydraulic cylinder stock. We also provide corresponding cutii de viteze agricole. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and să coopereze cu noi!

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cum funcționează cilindrul hidraulic pentru stivuitor?

Cilindru hidraulic Aplicație: