Double Shield TBM Support Shoe Cylinder

Fiind unul dintre producătorii, furnizorii și exportatorii de cilindri hidraulici, oferim cilindri hidraulici și multe alte produse.

Vă rugăm să luați legătura cu noi pentru detalii.

Mail:sales@hydraulic-cylinders.net

Producător, furnizor, exportator de cilindri hidraulici.

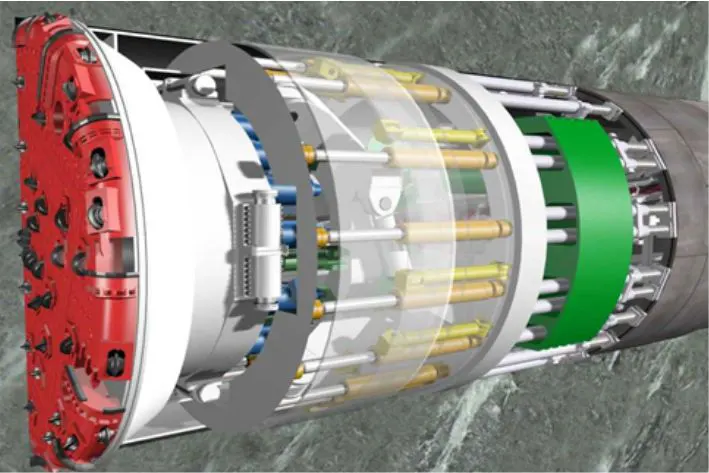

Double Shield TBM Support Shoe Cylinder

The double shield TBM support shoe cylinder is a cutting-edge hydraulic component designed to enhance tunnel boring operations’ efficiency and safety. This specialized cylinder plays a crucial role in supporting the shield of a double-shield tunnel boring machine (TBM), ensuring stability and protection during excavation. This informative article will explore the key characteristics, usage methods, and maintenance guidelines for the double shield tbm support shoe cylinder.

The double shield TBM support shoe cylinder is a vital component that enhances the efficiency and safety of double shield tunnel boring operations. With its improved stability, precise control, dual-acting design, durability, and reliability, this cylinder ensures secure support and protection of the TBM shield during excavation. By following the recommended usage methods and adhering to regular maintenance practices, the double shield tbm support shoe cylinder will continue to deliver outstanding performance, contributing to the success of tunneling projects. Experience the efficiency and safety of the double shield tbm support shoe cylinder, revolutionizing tunnel boring operations with advanced technology and reliability.

Double Shield TBM Support Shoe Cylinder Key Characteristics:

- Enhanced Stability and Load Bearing: The double shield TBM support shoe cylinder is engineered to provide exceptional stability and load-bearing capacity to the TBM shield. Its robust construction and precise engineering ensure that the shield remains securely in place during excavation, minimizing the risk of ground collapse and ensuring the safety of the tunneling crew.

- Precise Control and Positioning: Equipped with advanced hydraulic control systems, this cylinder offers precise control over the positioning of the support shoes. This allows operators to adjust the shoe’s orientation and alignment to match the specific ground conditions, ensuring accurate and efficient excavation.

- Dual-Acting Design: The double shield tbm support shoe cylinder features a dual-acting design, which means it can exert force in both the extension and retraction directions. This capability allows for versatile and controlled movement of the support shoes, providing optimal support and stability during the tunneling process.

- Durability and Reliability: Built with high-quality materials, the double shield tbm support shoe cylinder is designed to withstand the demanding conditions encountered during tunneling operations. It can withstand heavy loads, vibrations, and shocks, providing long-term durability, minimizing downtime, and reducing maintenance costs.

Double Shield TBM Support Shoe Cylinder Parameter:

| Product Name | Double Shield Tunnel Boring Machine Support Shoe Cylinder |

| Features: | Provides the thrust of cutterhead tunneling |

| Bore diameter: | 320mm~700mm |

| Rod diameter: | 220mm~500mm Stroke: 300mm~1200mm |

| Pressure: | up to 35MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield TBM Cylinder Application:

Usage Method Of Double Shield TBM Support Shoe Cylinder:

- Cylinder Installation: Install the double shield tbm support shoe cylinder according to the manufacturer’s instructions. Use suitable mounting brackets or accessories to ensure proper alignment and secure attachment to the TBM’s support shoe structure.

- Hydraulic System Integration: Connect the cylinder to the TBM’s hydraulic system using compatible hoses and fittings. Verify that all connections are secure, leak-free, and adequately tightened to ensure optimal hydraulic performance.

- Control and Positioning: Familiarize yourself with the rules specific to the double shield tbm support shoe cylinder. Use these controls to adjust the support shoes’ position, alignment, and angle as necessary. Follow the TBM manufacturer’s guidelines and recommendations for optimal support shoe positioning based on the ground conditions.

- Safety Precautions: Adhere to all safety protocols and guidelines provided by the TBM manufacturer. Ensure that operators are trained in the safe operation of the tbm and the double shield tbm support shoe cylinder. Regularly inspect safety mechanisms and perform maintenance as recommended to ensure proper functioning.

How To Build A Hydraulic Cylinder?

Building a hydraulic cylinder requires advanced engineering knowledge, specialized equipment, and access to high-quality materials. Due to the complexity and precision involved, it is typically a task undertaken by professional manufacturers. However, here is a general overview of the steps involved in building a hydraulic cylinder:

- Design and Engineering:

- Determine the specific requirements and specifications of the hydraulic cylinder, such as stroke length, bore diameter, operating pressure, and load capacity.

- Use computer-aided design (CAD) software to create a detailed plan that includes the cylinder’s dimensions, internal components, and seals.

- Material Selection:

- Choose high-quality materials for hydraulic applications, such as steel or aluminum for the cylinder barrel, piston, and end caps.

- Select appropriate seals, such as O-rings or piston seals, that can withstand the operating conditions and fluid compatibility.

- Machining:

- Use precision machining equipment, such as lathes, mills, and grinders, to fabricate the cylinder components according to the design specifications.

- Machine the cylinder barrel, end caps, piston, rod, and other internal components to the required dimensions and tolerances.

- Assembly:

- Clean all components thoroughly to remove any contaminants or debris.

- Install seals into the designated grooves on the piston, end caps, and rod.

- Carefully insert the piston into the cylinder barrel, ensuring proper alignment and clearance.

- Attach the end caps to the cylinder barrel, ensuring a secure and leak-free connection.

- Insert the rod into the piston and secure it with appropriate fasteners.

- Attach hydraulic fittings or ports to the end caps for fluid connections.

- Testing and Quality Control:

- Conduct pressure testing to ensure the cylinder can withstand the specified operating pressure without leaks or failures.

- Verify the proper functioning of the cylinder by extending and retracting it under controlled conditions.

- Inspect all components for defects or imperfections, ensuring they meet the required specifications.

- Perform quality control checks to ensure the cylinder meets safety and regulatory requirements.

Capabilitatea și capacitatea fabricii:

(1) Montaj

Avem o platformă de asamblare independentă de cercetare și dezvoltare de primă clasă. Atelierul de producție a cilindrilor hidraulici are patru linii de asamblare semiautomate pentru cilindri de ridicare și o linie de asamblare automată a cilindrilor de înclinare, cu o capacitate de producție anuală proiectată de 1 milion de bucăți. Atelierul de cilindri speciali este echipat cu diverse specificații ale unui sistem de asamblare semi-automat de curățare, cu o capacitate de producție anuală proiectată de 200.000 și dotat cu echipamente celebre de prelucrare CNC, un centru de prelucrare, un echipament special de prelucrare a cilindrilor de înaltă precizie, o mașină de sudură robotizată, o mașină de curățare automată, o mașină de asamblare automată a cilindrilor și o linie de producție automată de vopsire. Echipamente critice existente de peste 300 de seturi (seturi). Alocarea optimă și utilizarea eficientă a resurselor de echipamente asigură cerințele de precizie ale produselor și satisface nevoile de înaltă calitate ale produselor.

(2) Prelucrare

Atelierul de prelucrare este echipat cu un centru de strunjire cu șină înclinată personalizat, un centru de prelucrare, o mașină de honuire de mare viteză, un robot de sudură și alte echipamente conexe, care pot gestiona prelucrarea tuburilor cilindrice cu un diametru interior maxim de 400 mm și o lungime maximă de 6 metri.

(3) Sudură

(4) Vopsire și acoperire

Cu linii automate de acoperire cu vopsea pe bază de apă cu cilindru de dimensiuni mici și medii, pentru a realiza încărcarea și descărcarea automată a robotului și pulverizarea automată, capacitatea de proiectare de 4000 de bucăți pe schimb;

Avem, de asemenea, o linie de producție semi-automată de vopsire pentru cilindri mari, acționată de un lanț de putere, cu o capacitate de proiectare de 60 de cutii pe schimb.

(5) Testarea

Dispunem de instalații de inspecție și bancuri de testare de primă clasă pentru a ne asigura că performanța cilindrului îndeplinește cerințele.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding cutii de viteze agricole. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and să coopereze cu noi!

Faceți un tur al fabricii noastre VR:

Faceți un tur al fabricii noastre VR cu următoarele

Cum funcționează cilindrul hidraulic pentru stivuitor?

Cilindru hidraulic Aplicație: