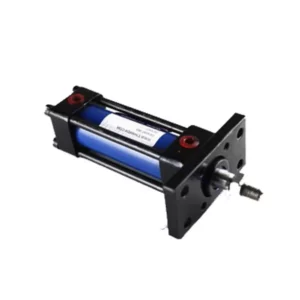

Double Acting

Hydraulic Cylinder

Double Acting Hydraulic Cylinders for Precision Control

Double Acting Hydraulic Cylinder For Sale

-

Cilindru hidraulic de înclinare a stivuitorului cu furcă

-

Cilindru hidraulic de direcție pentru stivuitoare

-

Cilindru hidraulic de reglare a distanței pentru stivuitoare

-

Cilindru hidraulic de joasă presiune pentru mașini-unelte

-

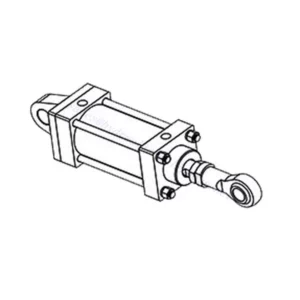

Cilindru hidraulic standard MOB Light Rod

-

FA Cilindru hidraulic cu flanșă frontală de tip Light Rod

-

Cilindru hidraulic cu tijă de lumină de tip piedestal LB

-

Cilindru hidraulic cu tijă ușoară de tip trunnion TC Middle Trunnion Type Light Rod

-

CA Monoaurală de tip cilindru hidraulic cu tijă ușoară CA

-

CA Monoaurală de tip Y Conector de tip Y Tijă de lumină Cilindru hidraulic

-

CA Monoaurală tip PHS Fisheye Conector de lumină cu tijă de lumină Cilindru hidraulic

-

CB Light Tie Rod Hydraulic Cylinder with Pin

Hydraulic Cylinder Production Area

We are a leading manufacturer specializing in hydraulic cylinders and hydraulic systems, dedicated to delivering high-tech solutions. Our company primarily serves OEMs in industries such as construction machinery, aerial work platforms, sanitation vehicles, wind power, and agricultural machinery. We offer a versatile range of hydraulic cylinders with inner diameters ranging from +20 to 500 mm, boasting an impressive annual design capacity of 1.2 million units.

Our state-of-the-art facilities include a provincial research institute, a high-tech R&D center, and a specialized hydraulic product testing laboratory. We utilize advanced equipment such as dedicated turning centers, high-speed cutting and polishing machines, automatic processing and welding systems, automatic cleaning and assembly lines, fully automated flexible painting lines, and intelligent logistics assembly lines. This comprehensive production and testing capability enables us to maintain a strong technological development capacity, ensuring our manufacturing processes and product quality meet advanced national standards.

Visit our VR hydraulic cylinder factory:

Production and Processing Workshop

Loading and Unloading Robots For Paint Lines

Product Testing Center

Cylinder Composite Machining Center

Automatic Cylinder Assembly Machine

With a robust quality assurance system in place, we have achieved ISO 9001 certification for quality management, as well as ISO 45001 for occupational health and safety, and ISO 14001 for environmental management. Our efficient, standardized processes and self-developed high-end equipment guarantee that our hydraulic cylinders are durable, pressure-resistant, leak-proof, and highly stable, with performance metrics that meet international benchmarks.

The “Huachang” series hydraulic cylinders are designed with a focus on structural integrity, reliable performance, and ease of maintenance. Their diverse structural forms allow for tailored solutions to meet specific customer needs. Coupled with our digital production management system, we respond quickly and effectively to customer requirements, ensuring that we exceed your expectations.

Choose us for high-quality hydraulic solutions that enhance your machinery’s performance and reliability.

Cylinder Assembly Line

Special Cylinder Testing Machine

Cylinder Inspection Area

Multi Station Welding Robot

Warehouse

Double Acting Hydraulic Cylinder Application

Material Handling,Construction,Industrial Production,Marine Applications

Material Handling

Construction

Industrial Production

Marine Applications

Frequently Asked Questions

A double acting hydraulic cylinder uses hydraulic pressure to extend and retract the piston, providing force in both directions for precise control.

This makes it ideal for applications like steering in forklifts or arm movement in excavators, where powered motion in both directions is essential.

This type of cylinder is used across industries for tasks requiring bidirectional force.

For example, a double acting hydraulic cylinder for forklifts ensures precise steering and tilting in material handling, while a double acting hydraulic cylinder for injection molding supports accurate mold operations in manufacturing.

Unlike single acting cylinders, which rely on external forces for retraction, a double acting hydraulic cylinder provides powered movement in both directions, offering greater control and flexibility.

This makes it the preferred choice for dynamic applications like telescoping in cranes or steering in heavy machinery.