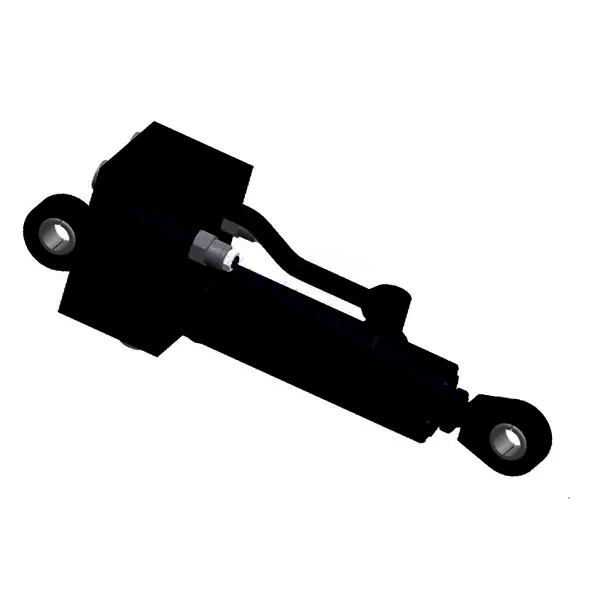

Ro-ro Platform Latch Cylinders (hydraulic self-locking)

Como um dos fabricantes, fornecedores e exportadores de produtos mecânicos de cilindros hidráulicos, oferecemos cilindros hidráulicos e muitos outros produtos.

Entre em contato conosco para obter detalhes.

Correio eletrônico:sales@hydraulic-cylinders.net

Fabricante, fornecedor e exportador de cilindros hidráulicos.

Ro-ro Platform Latch Cylinders (hydraulic self-locking)

Ro-ro platform latch cylinders with hydraulic self-locking capabilities are essential components designed to enhance the safety and efficiency of roll-on/roll-off (ro-ro) operations. These innovative hydraulic cylinders provide a reliable and convenient locking mechanism to secure the platform during transportation, preventing unwanted movement and ensuring the safe delivery of goods. With their exceptional features and hydraulic self-locking mechanism, ro-ro platform latch cylinders are the ultimate solution for companies seeking enhanced security and streamlined logistics.

Ro-ro platform latch cylinders with hydraulic self-locking capabilities provide the utmost security and efficiency in ro-ro operations. With their hydraulic self-locking mechanism, robust construction, and easy integration, these cylinders ensure safe and streamlined transportation of goods. By following the recommended usage methods and implementing regular maintenance practices, companies can maximize the longevity and performance of these essential components, contributing to enhanced security and smooth logistics operations.

Ro-ro Platform Latch Cylinders (hydraulic self-locking) Key Characteristics:

- Hydraulic Self-Locking: Ro-ro platform latch cylinders feature a hydraulic self-locking mechanism that securely locks the platform once engaged. This eliminates the need for external locking devices, reducing complexity and increasing operational efficiency.

- Robust Construction: These cylinders are built with high-quality materials to withstand the demanding conditions of ro-ro operations. Their robust construction ensures durability and longevity, minimizing downtime and maintenance costs.

- Easy Integration: Ro-ro platform latch cylinders are designed for easy integration into existing ro-ro platform systems. They can be seamlessly installed and retrofitted, enabling quick and hassle-free implementation.

- Enhanced Safety: The hydraulic self-locking mechanism of these cylinders ensures that the platform remains securely locked during transportation. This feature significantly reduces the risk of accidents, preventing cargo shifts and enhancing overall safety.

Ro-ro Platform Latch Cylinders (hydraulic self-locking) Parameter:

| Product Name | Ro-ro Platform Latch Cylinder |

| Features: | Lock the bolt after the springboard or ramp is recovered in place |

| Specification: | Specifications: 80/50*S, 63/40*S, 40/28*S,front and rear Having DNVGL type approval With standard size series selection |

| Pressure | 25MPa (stainless steel piston rod) |

| Applications: | Ro-ro Platform |

Having DNVGL type approval

With standard size series selection

(stainless steel piston rod)

Ro-ro Platform Main Operating Cylinder Application:

Usage Method Of Ro-ro Platform Latch Cylinders (hydraulic self-locking):

- Installation: Ro-ro platform latch cylinders are installed strategically on the ro-ro platform. Mount the cylinders securely using appropriate brackets and hardware, ensuring proper alignment and clearance for operation.

- Activation: Once the platform is positioned and ready for transport, activate the hydraulic self-locking mechanism. This can be achieved through manual engagement or automated systems, depending on the specific design and requirements.

- Locking Verification: After engaging the self-locking mechanism, verify that the cylinders are securely locked and holding the platform. Perform visual inspections and functional tests to ensure proper engagement and functionality.

How Do Rephasing Hydraulic Cylinders Work?

The basic principle behind rephasing hydraulic cylinders is using interconnected fluid lines that allow for transferring hydraulic fluid between the cylinders. This interconnection enables the cylinders to share the load and maintain equal stroke lengths, regardless of variations in the bag or resistance encountered by each cylinder.

Here’s a step-by-step breakdown of how rephasing hydraulic cylinders works:

- Interconnected Fluid Lines: Rephasing cylinders are connected through fluid lines or passages. These lines allow hydraulic fluid to flow between the cylinders, creating a shared hydraulic system.

- Initial Positioning: The cylinders are initially positioned at the same starting point. This ensures they have the same starting stroke length and are ready to move in unison.

- Hydraulic Fluid Transfer: As hydraulic fluid is pumped into the system, it flows through the interconnected lines. The fluid pressure causes the cylinders to extend, and the liquid is distributed between the cylinders, maintaining equal pressure throughout the system.

- Load Distribution: When a load is applied to the rephasing cylinders, each cylinder experiences different resistance levels or forces. The cylinders with less resistance will extend further, while those with more resistance will extend less. This difference in extension causes the hydraulic fluid to flow from the more extended cylinder to the less comprehensive cylinder through the interconnected lines.

- Equalizing Stroke Lengths: The stroke lengths begin to equalize as the hydraulic fluid transfers between the cylinders. The cylinders adjust their extension levels until the load is distributed evenly, resulting in synchronized movement and equal stroke lengths.

- Balanced Force: Once the stroke lengths are equalized, the rephasing cylinders exert equal force on the load. This ensures balanced force distribution and prevents uneven loading or tilting of the system.

- Simultaneous Retraction: When the hydraulic system is reversed, or the cylinders need to retract, the fluid flow is reversed. The fluid is transferred back to the retracting cylinders, ensuring synchronized retraction and equal stroke lengths.

Aptidão e capacidade da fábrica:

(1) Montagem

Temos uma plataforma de montagem de pesquisa e desenvolvimento independente de primeira classe. A oficina de produção de cilindros hidráulicos tem quatro linhas de montagem semiautomáticas de cilindros de elevação e uma linha de montagem automática de cilindros de inclinação, com uma capacidade de produção anual projetada de 1 milhão de peças. A oficina de cilindros especiais é equipada com várias especificações de um sistema de montagem de limpeza semiautomática com uma capacidade de produção anual projetada de 200.000 peças e equipada com famosos equipamentos de usinagem CNC, um centro de usinagem, um equipamento especial de processamento de cilindros de alta precisão, uma máquina de solda robotizada, uma máquina de limpeza automática, uma máquina de montagem automática de cilindros e uma linha de produção de pintura automática. O equipamento crítico existente é de mais de 300 conjuntos (conjuntos). A alocação ideal e o uso eficiente dos recursos do equipamento garantem os requisitos de precisão dos produtos e atendem às necessidades de alta qualidade dos produtos.

(2) Usinagem

A oficina de usinagem é equipada com um centro de torneamento de trilho inclinado personalizado, um centro de usinagem, uma máquina de brunimento de alta velocidade, um robô de soldagem e outros equipamentos relacionados, que podem lidar com o processamento de tubos de cilindros com diâmetro interno máximo de 400 mm e comprimento máximo de 6 metros.

(3) Soldagem

(4) Pintura e revestimento

Com linhas de revestimento de tinta à base de água automáticas de cilindros de pequeno e médio porte, para obter carregamento e descarregamento automáticos de robôs e pulverização automática, a capacidade projetada é de 4.000 peças por turno;

Também temos uma linha de produção de tinta semiautomática para cilindros grandes, acionada por uma corrente elétrica, com capacidade de projeto de 60 caixas por turno.

(5) Testes

Temos instalações de inspeção e bancos de teste de primeira classe para garantir que o desempenho do cilindro atenda aos requisitos.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding caixas de câmbio agrícolas. Exportamos nossos produtos para clientes em todo o mundo e conquistamos uma boa reputação devido à qualidade superior de nossos produtos e ao serviço pós-venda. Convidamos clientes nacionais e estrangeiros a entrar em contato conosco para negociar negócios, trocar informações e cooperar conosco!

Faça um tour pela nossa fábrica de RV:

Faça um tour pela nossa fábrica de RV com o seguinte

Cilindro hidráulico Aplicação: