Large Excavator Boom Cylinder

Como um dos fabricantes, fornecedores e exportadores de produtos mecânicos de cilindros hidráulicos, oferecemos cilindros hidráulicos e muitos outros produtos.

Entre em contato conosco para obter detalhes.

Correio eletrônico:sales@hydraulic-cylinders.net

Fabricante, fornecedor e exportador de cilindros hidráulicos.

Large Excavator Boom Cylinder

The large excavator boom cylinder is a vital hydraulic component that plays a crucial role in efficiently operating large excavators. This cylinder is specifically designed to provide powerful extension and retraction of the boom, enabling precise control and enhanced performance in heavy construction projects.

The large excavator boom cylinder is a powerful hydraulic component vital in efficiently operating large excavators. With its robust construction, precise control, extended reach, and lifting capacity, this cylinder empowers operators to achieve enhanced performance and productivity in heavy construction projects. By following the recommended usage methods and maintenance practices, operators can ensure optimal performance and longevity of the large excavator boom cylinder, resulting in increased efficiency and successful completion of construction tasks. Invest in this exceptional hydraulic cylinder to unleash the full potential of your large excavator and elevate your construction capabilities to new heights.

Large Excavator Bucket Cylinder Key Characteristics:

- Robust Construction and High Strength

- The large excavator boom cylinder is built with durable materials and boasts a robust construction that ensures optimal performance even in demanding conditions.

- It possesses high-strength capabilities, allowing it to withstand heavy loads and exert significant force during operation.

- Precise Control and Smooth Operation

- This cylinder offers precise control over the extension and retraction of the boom, enabling operators to achieve accurate positioning and maneuverability.

- It provides smooth and seamless operation, minimizing jerky movements and optimizing efficiency during construction tasks.

- Extended Reach and Lifting Capacity

- With its impressive extension capabilities, the large excavator boom cylinder enables the excavator to reach greater distances, expanding its working range.

- It enhances the excavator’s lifting capacity, allowing for efficient handling of heavy materials and improved productivity on the job site.

- Compatibility and Adaptability

- The large excavator boom cylinder is designed to be compatible with a wide range of large excavator models, ensuring versatility and ease of integration.

- It can easily adapt to different boom configurations, making it a versatile hydraulic component for various construction applications.

Large Excavator Boom Cylinder Parameter:

| Product Name | Large Excavator Boom Cylinder |

| Features: | Control the lifting motion of the big arm |

| Bore diameter: | 200mm~420mm |

| Rod diameter: | 140mm~300mm Stroke≤3500mm |

| Thrust force: | Maximum 4846.6KN |

| Bore diameter: | 420mm/pressure35MPa |

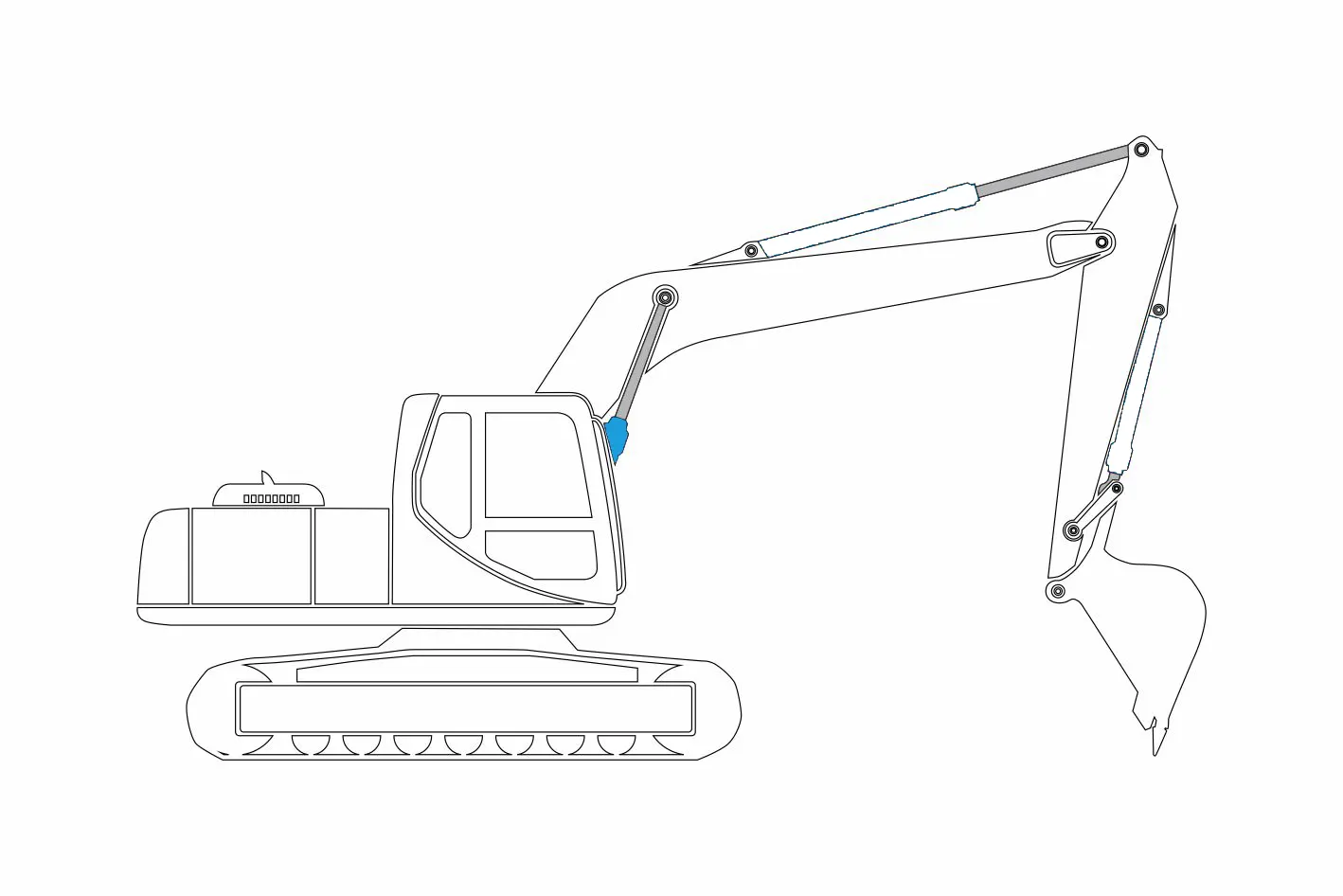

Large Excavator Boom Cylinder Identification Diagram:

Usage Method Of Large Excavator Boom Cylinder:

- Installation and Configuration

- Follow the manufacturer’s guidelines for proper installation of the large excavator boom cylinder.

- Ensure compatibility and securely attach the cylinder to the boom assembly of the excavator.

- Use the recommended torque specifications and appropriate mounting hardware to establish a reliable connection.

- Operational Considerations

- Familiarize yourself with the controls and operation of the large excavator, including the boom cylinder.

- Practice operating the excavator and cylinder in a controlled environment before undertaking construction tasks.

- Adhere to safety guidelines and operate within the excavator’s load limits to ensure safety and prevent equipment damage.

- Optimizing Performance

- Utilize the precise control the large excavator boom cylinder offers to optimize performance during construction projects.

- Extend and retract the boom as required for specific tasks, ensuring precise placement of materials and efficient digging or lifting.

- Adjust the boom angle and height according to the project requirements, maximizing reach and productivity on the job site.

What Size Cylinder For Excavator Thumb?

The size of the cylinder for an excavator’s thumb can vary depending on the specific requirements of the excavator and the intended use of the thumb attachment. The appropriate size of the cylinder is typically determined by considering factors such as the excavator’s operating weight, the desired lifting capacity of the thumb, and compatibility with the excavator’s hydraulic system.

To determine the suitable cylinder size for an excavator thumb, it is recommended to consult the manufacturer or supplier of the thumb attachment. They can provide guidance based on the excavator’s specifications and the thumb’s intended application.

It’s worth noting that excavator thumbs are available in various sizes and configurations to accommodate different excavator models and sizes. The thumb attachment typically consists of a central structure or frame that mounts to the excavator’s boom and a hydraulic cylinder that provides the gripping or clamping action. The cylinder size should be selected to ensure compatibility with the thumb attachment and to provide the required gripping force for the intended tasks.

When considering the cylinder size for an excavator’s thumb, it’s essential to strike a balance between having sufficient lifting capacity and ensuring that the excavator’s hydraulic system can adequately support the operation of the thumb. Oversizing the cylinder may strain the excavator’s hydraulic system excessively, while under sizing, may result in limited lifting capacity and reduced performance.

In summary, the size of the cylinder for an excavator thumb should be determined based on factors such as the excavator’s operating weight, desired lifting capacity, and compatibility with the thumb attachment and hydraulic system. Consulting the manufacturer or supplier of the thumb attachment is recommended to ensure proper sizing and optimal performance.

Aptidão e capacidade da fábrica:

(1) Montagem

Temos uma plataforma de montagem de pesquisa e desenvolvimento independente de primeira classe. A oficina de produção de cilindros hidráulicos tem quatro linhas de montagem semiautomáticas de cilindros de elevação e uma linha de montagem automática de cilindros de inclinação, com uma capacidade de produção anual projetada de 1 milhão de peças. A oficina de cilindros especiais é equipada com várias especificações de um sistema de montagem de limpeza semiautomática com uma capacidade de produção anual projetada de 200.000 peças e equipada com famosos equipamentos de usinagem CNC, um centro de usinagem, um equipamento especial de processamento de cilindros de alta precisão, uma máquina de solda robotizada, uma máquina de limpeza automática, uma máquina de montagem automática de cilindros e uma linha de produção de pintura automática. O equipamento crítico existente é de mais de 300 conjuntos (conjuntos). A alocação ideal e o uso eficiente dos recursos do equipamento garantem os requisitos de precisão dos produtos e atendem às necessidades de alta qualidade dos produtos.

(2) Usinagem

A oficina de usinagem é equipada com um centro de torneamento de trilho inclinado personalizado, um centro de usinagem, uma máquina de brunimento de alta velocidade, um robô de soldagem e outros equipamentos relacionados, que podem lidar com o processamento de tubos de cilindros com diâmetro interno máximo de 400 mm e comprimento máximo de 6 metros.

(3) Soldagem

(4) Pintura e revestimento

Com linhas de revestimento de tinta à base de água automáticas de cilindros de pequeno e médio porte, para obter carregamento e descarregamento automáticos de robôs e pulverização automática, a capacidade projetada é de 4.000 peças por turno;

Também temos uma linha de produção de tinta semiautomática para cilindros grandes, acionada por uma corrente elétrica, com capacidade de projeto de 60 caixas por turno.

(5) Testes

Temos instalações de inspeção e bancos de teste de primeira classe para garantir que o desempenho do cilindro atenda aos requisitos.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding caixas de câmbio agrícolas. Exportamos nossos produtos para clientes em todo o mundo e conquistamos uma boa reputação devido à qualidade superior de nossos produtos e ao serviço pós-venda. Convidamos clientes nacionais e estrangeiros a entrar em contato conosco para negociar negócios, trocar informações e cooperar conosco!

Faça um tour pela nossa fábrica de RV:

Faça um tour pela nossa fábrica de RV com o seguinte

Como funciona o cilindro hidráulico da empilhadeira?

Cilindro hidráulico Aplicação: