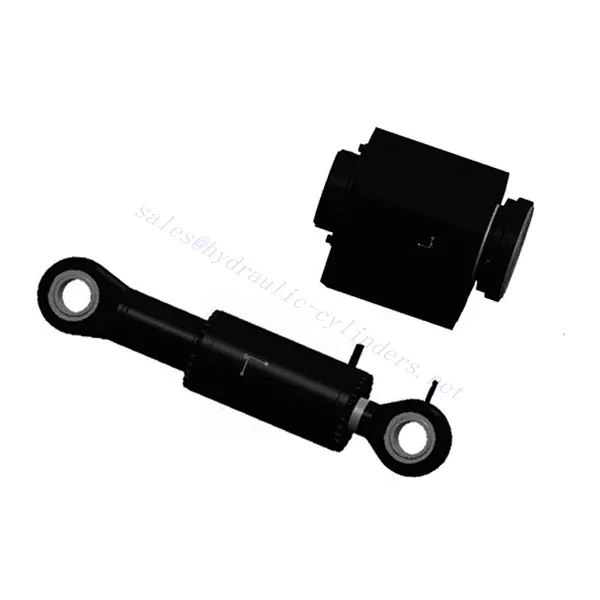

Double Shield TBM Torque Cylinder

Como um dos fabricantes, fornecedores e exportadores de produtos mecânicos de cilindros hidráulicos, oferecemos cilindros hidráulicos e muitos outros produtos.

Entre em contato conosco para obter detalhes.

Correio eletrônico:sales@hydraulic-cylinders.net

Fabricante, fornecedor e exportador de cilindros hidráulicos.

Double Shield TBM Torque Cylinder

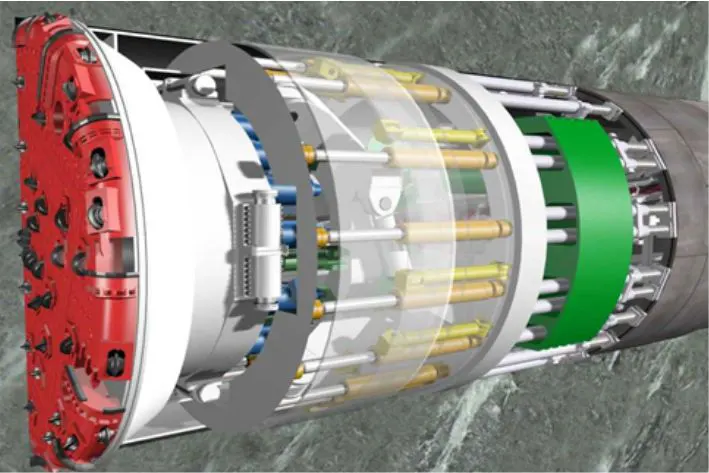

The double shield TBM torque cylinder is a cutting-edge hydraulic component that maximizes the efficiency and accuracy of tunnel boring machines. This specialized cylinder provides the necessary torque force for the rotation of the cutterhead, enabling smooth and precise excavation during tunneling operations. This comprehensive article will explore the key characteristics, usage methods, and maintenance guidelines for the double shield tbm torque cylinder.

The double shield TBM torque cylinder is a robust and reliable component revolutionizing tunnel boring operations. With its high torque output, precision engineering, rugged construction, and space-efficient design, this cylinder enhances the efficiency and accuracy of tunneling processes. By following the recommended usage methods and adhering to regular maintenance practices, the double shield tbm torque cylinder will continue to deliver exceptional performance, contributing to the success of tunneling projects. Embrace the power and precision of the double shield tbm torque cylinder, unleashing the full potential of tunnel dull with unparalleled efficiency and accuracy.

Double Shield TBM Torque Cylinder Key Characteristics:

- High Torque Output: The double TBM shield torque cylinder delivers a robust torque output, enabling efficient rotation of the cutterhead. Its powerful performance ensures effective and precise excavation, even in challenging geological conditions.

- Precision Engineering: This cylinder is engineered precisely to ensure smooth and accurate torque transmission. Its advanced design minimizes backlash and maintains consistent rotational speeds, resulting in precise excavation and improved tunneling productivity.

- Robust Construction: The double shield TBM torque cylinder features a sturdy construction built to withstand the demanding conditions encountered during tunnel boring. Its high-quality materials and meticulous craftsmanship ensure durability and reliability in the harshest environments.

- Compact and Space-Efficient: This cylinder optimizes space utilization within the tunnel boring machine with a compact design. Its streamlined construction allows for easy integration, minimizing interference with other components and maximizing the overall efficiency of the tunneling process.

Double Shield TBM Torque Cylinder Parameter:

| Product Name | Double Shield Tunnel Boring Machine Torque Cylinder |

| Features: | Transmit the torque of the cutter head |

| Specification: | Various structures and specifications of torque cylinders can be designed and produced according to customer requirements |

| Pressure: | up to 25MPa Special requirements up to 35MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield TBM Cylinder Application:

Usage Method Of Double Shield TBM Torque Cylinder:

- Cylinder Integration: Install the double shield tbm torque cylinder in the designated location within the tunnel boring machine, following the manufacturer’s guidelines and specifications. Ensure proper alignment and secure attachment to the TBM’s structure using suitable mounting brackets or accessories.

- Hydraulic System Integration: Connect the cylinder to the TBM’s hydraulic system using compatible hoses and fittings. Verify that all connections are secure, leak-free, and adequately tightened to ensure optimal hydraulic performance.

- Control and Operation: Familiarize yourself with the TBM’s control system and the rules associated with the double shield tbm torque cylinder. Utilize these controls to activate, regulate, and monitor the torque output, adjusting it to match the excavation requirements and geological conditions.

- Monitoring and Adjustment: Continuously monitor the performance of the double shield tbm torque cylinder and the overall behavior of the tunnel boring machine. Adjust the torque output, considering ground conditions, cutter wear, and excavation progress to ensure optimal efficiency and productivity.

How To Change Hydraulic Cylinder Seals?

Changing hydraulic cylinder seals requires careful disassembly and reassembly of the cylinder components. Here is a step-by-step guide to help you through the process:

- Prepare the Cylinder:

- Disconnect the hydraulic cylinder from the system and ensure it is depressurized.

- Clean the exterior of the cylinder to prevent dirt or debris from entering during disassembly.

- Place the cylinder on a stable work surface and secure it using clamps or a vise.

- Identify the Seals:

- Determine the types and locations of the seals that need replacement.

- Hydraulic cylinders typically have multiple seals, including rod seals, piston seals, and wiper seals.

- Consult the manufacturer’s documentation or reference materials to identify the required seals.

- Disassembly:

- Remove any retaining components such as bolts, snap rings, or retaining rings that secure the cylinder head or cap.

- Carefully remove the cylinder head or cap, exposing the piston, rod, and seals.

- Pay attention to the arrangement and order of the seals for proper reassembly.

- Remove the Old Seals:

- Inspect the old seals for damage or wear and identify the appropriate removal method.

- Depending on the seal type, you may need to use seal removal tools, such as picks or hooks, or carefully pry them out using a flat-blade screwdriver.

- Take care not to damage the cylinder surfaces during seal removal.

- Clean and Inspect:

- Thoroughly clean the cylinder bore, rod, and surrounding components using a lint-free cloth or a suitable solvent.

- Inspect all components for any signs of damage, wear, or scoring. Replace any worn or damaged parts as necessary.

- Install the New Seals:

- Apply a thin layer of hydraulic fluid or seal lubricant to the new seals to aid in installation and ensure proper sealing.

- Carefully position the new seals in their grooves, ensuring they are correctly oriented.

- Use a seal installation tool or a soft mallet to gently press the seals into place, ensuring they are seated evenly and securely.

- Remontagem:

- Reinstall any remaining components removed during disassembly, such as bolts, snap rings, or retaining rings.

- Follow the manufacturer’s torque values and tightening sequence specifications to ensure proper sealing and alignment.

- Double-check the order and arrangement of the seals to ensure they are in the correct position.

- Testing and Verification:

- Reconnect the hydraulic cylinder to the system and ensure all connections are secure.

- Gradually restore system pressure, checking for any leaks or abnormal behavior.

- Cycle the hydraulic cylinder through its full range of motion to verify proper seal operation and overall functionality.

Aptidão e capacidade da fábrica:

(1) Montagem

Temos uma plataforma de montagem de pesquisa e desenvolvimento independente de primeira classe. A oficina de produção de cilindros hidráulicos tem quatro linhas de montagem semiautomáticas de cilindros de elevação e uma linha de montagem automática de cilindros de inclinação, com uma capacidade de produção anual projetada de 1 milhão de peças. A oficina de cilindros especiais é equipada com várias especificações de um sistema de montagem de limpeza semiautomática com uma capacidade de produção anual projetada de 200.000 peças e equipada com famosos equipamentos de usinagem CNC, um centro de usinagem, um equipamento especial de processamento de cilindros de alta precisão, uma máquina de solda robotizada, uma máquina de limpeza automática, uma máquina de montagem automática de cilindros e uma linha de produção de pintura automática. O equipamento crítico existente é de mais de 300 conjuntos (conjuntos). A alocação ideal e o uso eficiente dos recursos do equipamento garantem os requisitos de precisão dos produtos e atendem às necessidades de alta qualidade dos produtos.

(2) Usinagem

A oficina de usinagem é equipada com um centro de torneamento de trilho inclinado personalizado, um centro de usinagem, uma máquina de brunimento de alta velocidade, um robô de soldagem e outros equipamentos relacionados, que podem lidar com o processamento de tubos de cilindros com diâmetro interno máximo de 400 mm e comprimento máximo de 6 metros.

(3) Soldagem

(4) Pintura e revestimento

Com linhas de revestimento de tinta à base de água automáticas de cilindros de pequeno e médio porte, para obter carregamento e descarregamento automáticos de robôs e pulverização automática, a capacidade projetada é de 4.000 peças por turno;

Também temos uma linha de produção de tinta semiautomática para cilindros grandes, acionada por uma corrente elétrica, com capacidade de projeto de 60 caixas por turno.

(5) Testes

Temos instalações de inspeção e bancos de teste de primeira classe para garantir que o desempenho do cilindro atenda aos requisitos.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding caixas de câmbio agrícolas. Exportamos nossos produtos para clientes em todo o mundo e conquistamos uma boa reputação devido à qualidade superior de nossos produtos e ao serviço pós-venda. Convidamos clientes nacionais e estrangeiros a entrar em contato conosco para negociar negócios, trocar informações e cooperar conosco!

Faça um tour pela nossa fábrica de RV:

Faça um tour pela nossa fábrica de RV com o seguinte

Como funciona o cilindro hidráulico da empilhadeira?

Cilindro hidráulico Aplicação: