Double Shield TBM Support Shoe Cylinder

Como um dos fabricantes, fornecedores e exportadores de produtos mecânicos de cilindros hidráulicos, oferecemos cilindros hidráulicos e muitos outros produtos.

Entre em contato conosco para obter detalhes.

Correio eletrônico:sales@hydraulic-cylinders.net

Fabricante, fornecedor e exportador de cilindros hidráulicos.

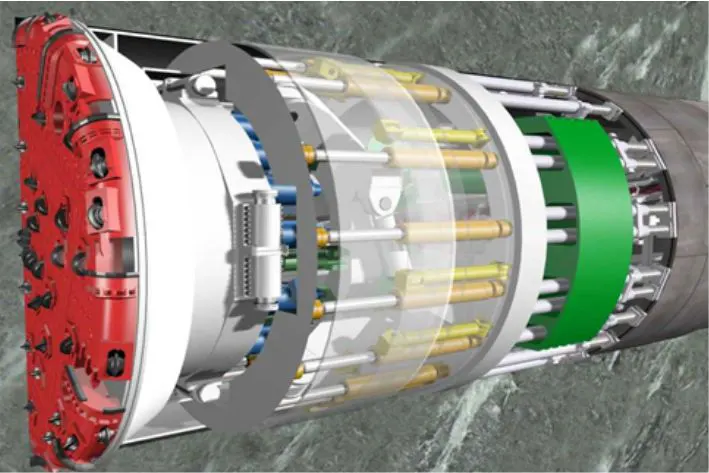

Double Shield TBM Support Shoe Cylinder

The double shield TBM support shoe cylinder is a cutting-edge hydraulic component designed to enhance tunnel boring operations’ efficiency and safety. This specialized cylinder plays a crucial role in supporting the shield of a double-shield tunnel boring machine (TBM), ensuring stability and protection during excavation. This informative article will explore the key characteristics, usage methods, and maintenance guidelines for the double shield tbm support shoe cylinder.

The double shield TBM support shoe cylinder is a vital component that enhances the efficiency and safety of double shield tunnel boring operations. With its improved stability, precise control, dual-acting design, durability, and reliability, this cylinder ensures secure support and protection of the TBM shield during excavation. By following the recommended usage methods and adhering to regular maintenance practices, the double shield tbm support shoe cylinder will continue to deliver outstanding performance, contributing to the success of tunneling projects. Experience the efficiency and safety of the double shield tbm support shoe cylinder, revolutionizing tunnel boring operations with advanced technology and reliability.

Double Shield TBM Support Shoe Cylinder Key Characteristics:

- Enhanced Stability and Load Bearing: The double shield TBM support shoe cylinder is engineered to provide exceptional stability and load-bearing capacity to the TBM shield. Its robust construction and precise engineering ensure that the shield remains securely in place during excavation, minimizing the risk of ground collapse and ensuring the safety of the tunneling crew.

- Precise Control and Positioning: Equipped with advanced hydraulic control systems, this cylinder offers precise control over the positioning of the support shoes. This allows operators to adjust the shoe’s orientation and alignment to match the specific ground conditions, ensuring accurate and efficient excavation.

- Dual-Acting Design: The double shield tbm support shoe cylinder features a dual-acting design, which means it can exert force in both the extension and retraction directions. This capability allows for versatile and controlled movement of the support shoes, providing optimal support and stability during the tunneling process.

- Durability and Reliability: Built with high-quality materials, the double shield tbm support shoe cylinder is designed to withstand the demanding conditions encountered during tunneling operations. It can withstand heavy loads, vibrations, and shocks, providing long-term durability, minimizing downtime, and reducing maintenance costs.

Double Shield TBM Support Shoe Cylinder Parameter:

| Product Name | Double Shield Tunnel Boring Machine Support Shoe Cylinder |

| Features: | Provides the thrust of cutterhead tunneling |

| Bore diameter: | 320mm~700mm |

| Rod diameter: | 220mm~500mm Stroke: 300mm~1200mm |

| Pressure: | up to 35MPa |

| Applications: | Double Shield Tunnel Boring Machine |

Double Shield TBM Cylinder Application:

Método de uso de Double Shield TBM Support Shoe Cylinder:

- Instalação do cilindro: Install the double shield tbm support shoe cylinder according to the manufacturer’s instructions. Use suitable mounting brackets or accessories to ensure proper alignment and secure attachment to the TBM’s support shoe structure.

- Hydraulic System Integration: Connect the cylinder to the TBM’s hydraulic system using compatible hoses and fittings. Verify that all connections are secure, leak-free, and adequately tightened to ensure optimal hydraulic performance.

- Control and Positioning: Familiarize yourself with the rules specific to the double shield tbm support shoe cylinder. Use these controls to adjust the support shoes’ position, alignment, and angle as necessary. Follow the TBM manufacturer’s guidelines and recommendations for optimal support shoe positioning based on the ground conditions.

- Precauções de segurança: Adhere to all safety protocols and guidelines provided by the TBM manufacturer. Ensure that operators are trained in the safe operation of the tbm and the double shield tbm support shoe cylinder. Regularly inspect safety mechanisms and perform maintenance as recommended to ensure proper functioning.

How To Build A Hydraulic Cylinder?

Building a hydraulic cylinder requires advanced engineering knowledge, specialized equipment, and access to high-quality materials. Due to the complexity and precision involved, it is typically a task undertaken by professional manufacturers. However, here is a general overview of the steps involved in building a hydraulic cylinder:

- Design and Engineering:

- Determine the specific requirements and specifications of the hydraulic cylinder, such as stroke length, bore diameter, operating pressure, and load capacity.

- Use computer-aided design (CAD) software to create a detailed plan that includes the cylinder’s dimensions, internal components, and seals.

- Material Selection:

- Choose high-quality materials for hydraulic applications, such as steel or aluminum for the cylinder barrel, piston, and end caps.

- Select appropriate seals, such as O-rings or piston seals, that can withstand the operating conditions and fluid compatibility.

- Machining:

- Use precision machining equipment, such as lathes, mills, and grinders, to fabricate the cylinder components according to the design specifications.

- Machine the cylinder barrel, end caps, piston, rod, and other internal components to the required dimensions and tolerances.

- Assembly:

- Clean all components thoroughly to remove any contaminants or debris.

- Install seals into the designated grooves on the piston, end caps, and rod.

- Carefully insert the piston into the cylinder barrel, ensuring proper alignment and clearance.

- Attach the end caps to the cylinder barrel, ensuring a secure and leak-free connection.

- Insert the rod into the piston and secure it with appropriate fasteners.

- Attach hydraulic fittings or ports to the end caps for fluid connections.

- Testing and Quality Control:

- Conduct pressure testing to ensure the cylinder can withstand the specified operating pressure without leaks or failures.

- Verify the proper functioning of the cylinder by extending and retracting it under controlled conditions.

- Inspect all components for defects or imperfections, ensuring they meet the required specifications.

- Perform quality control checks to ensure the cylinder meets safety and regulatory requirements.

Aptidão e capacidade da fábrica:

(1) Montagem

Temos uma plataforma de montagem de pesquisa e desenvolvimento independente de primeira classe. A oficina de produção de cilindros hidráulicos tem quatro linhas de montagem semiautomáticas de cilindros de elevação e uma linha de montagem automática de cilindros de inclinação, com uma capacidade de produção anual projetada de 1 milhão de peças. A oficina de cilindros especiais é equipada com várias especificações de um sistema de montagem de limpeza semiautomática com uma capacidade de produção anual projetada de 200.000 peças e equipada com famosos equipamentos de usinagem CNC, um centro de usinagem, um equipamento especial de processamento de cilindros de alta precisão, uma máquina de solda robotizada, uma máquina de limpeza automática, uma máquina de montagem automática de cilindros e uma linha de produção de pintura automática. O equipamento crítico existente é de mais de 300 conjuntos (conjuntos). A alocação ideal e o uso eficiente dos recursos do equipamento garantem os requisitos de precisão dos produtos e atendem às necessidades de alta qualidade dos produtos.

(2) Usinagem

A oficina de usinagem é equipada com um centro de torneamento de trilho inclinado personalizado, um centro de usinagem, uma máquina de brunimento de alta velocidade, um robô de soldagem e outros equipamentos relacionados, que podem lidar com o processamento de tubos de cilindros com diâmetro interno máximo de 400 mm e comprimento máximo de 6 metros.

(3) Soldagem

(4) Pintura e revestimento

Com linhas de revestimento de tinta à base de água automáticas de cilindros de pequeno e médio porte, para obter carregamento e descarregamento automáticos de robôs e pulverização automática, a capacidade projetada é de 4.000 peças por turno;

Também temos uma linha de produção de tinta semiautomática para cilindros grandes, acionada por uma corrente elétrica, com capacidade de projeto de 60 caixas por turno.

(5) Testes

Temos instalações de inspeção e bancos de teste de primeira classe para garantir que o desempenho do cilindro atenda aos requisitos.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding caixas de câmbio agrícolas. Exportamos nossos produtos para clientes em todo o mundo e conquistamos uma boa reputação devido à qualidade superior de nossos produtos e ao serviço pós-venda. Convidamos clientes nacionais e estrangeiros a entrar em contato conosco para negociar negócios, trocar informações e cooperar conosco!

Faça um tour pela nossa fábrica de RV:

Faça um tour pela nossa fábrica de RV com o seguinte

Como funciona o cilindro hidráulico da empilhadeira?

Cilindro hidráulico Aplicação: