Lifting Cylinder For Scissor Type Aerial Work Vehicles

Jako jeden z producentów, dostawców i eksporterów produktów mechanicznych, oferujemy cylindry hydrauliczne i wiele innych produktów.

Prosimy o kontakt w celu uzyskania szczegółowych informacji.

Poczta:sales@hydraulic-cylinders.net

Producent dostawca eksporter siłowników hydraulicznych.

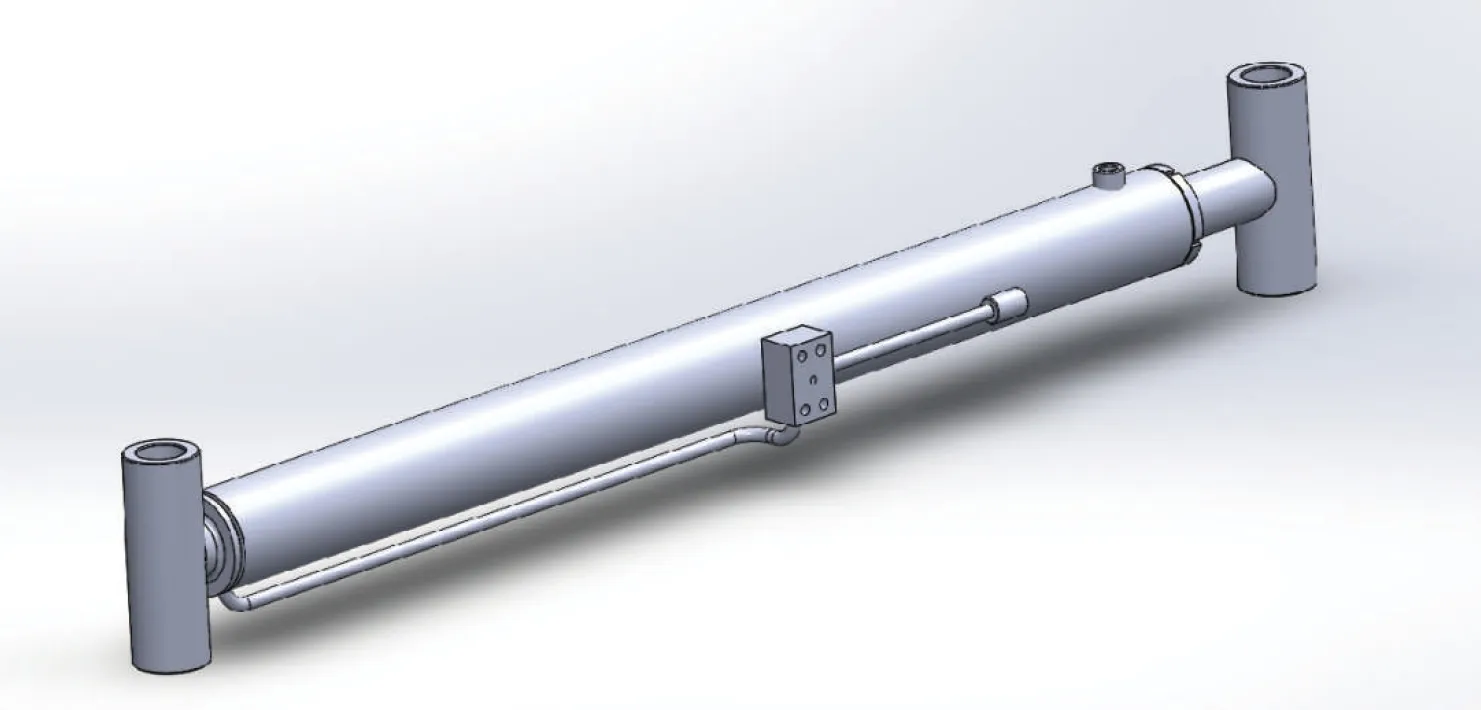

High-Performance Lifting Cylinder for Scissor Type Aerial Work Vehicles

Our lifting cylinder for scissor type aerial work vehicles delivers exceptional strength and precision for demanding high-altitude tasks. Engineered for articulated and telescopic boom lifts, our hydraulic cylinders ensure smooth, controlled lifting and unwavering stability, making them a trusted choice for aerial platforms. Designed for seamless compatibility with leading equipment, they excel in construction, facility maintenance, and municipal services, enhancing operational efficiency.

With robust construction and advanced seals, our cylinders minimize maintenance needs while maximizing durability in harsh environments. ISO-certified and backed our expertise, each lifting cylinder for scissor type aerial work vehicles is tailored to meet your specific requirements, offering reliable performance for years. Whether powering a boom lift or supporting critical infrastructure projects, our solutions elevate productivity and safety. Choose Huachang for high-performance hydraulic cylinders that set the standard in aerial work applications.

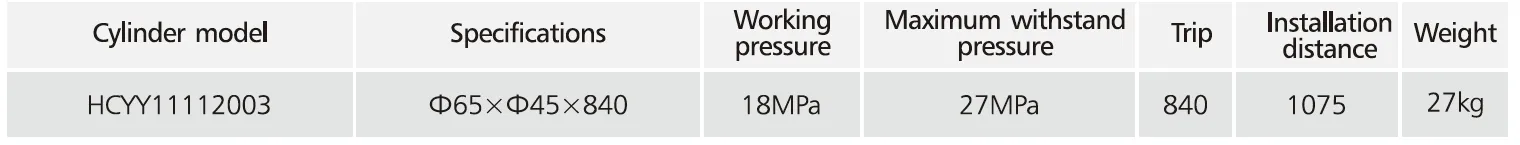

Lifting Cylinder For Scissor Type Aerial Work Vehicles Parameter:

Function: Implement the upward and downward movements of the scissor fork

Cylinder Diameter: 55mm-380mm

Rod Diameter: 40mm-200mm

Travel: 280mm -2193mm

Maximum Pressure: 25MPa

Maximum Thrust: 2835KN

Cylinder Series For Scissor Type Aerial Work Vehicles:

Key Features of Lifting Cylinder For Scissor Type Aerial Work Vehicles:

Huachang’s lifting cylinder for scissor type aerial work vehicles is engineered with cutting-edge technology to deliver exceptional performance in high-altitude operations. Designed for articulated and telescopic boom lifts, these hydraulic cylinders offer a perfect blend of strength, precision, and durability. Explore the key features that make our cylinders the preferred choice for construction, maintenance, and municipal applications.

- High Load Capacity: Built to handle substantial loads, this durable hydraulic cylinder for boom lift supports heavy-duty aerial work platforms with ease. Its robust design ensures reliable lifting for demanding tasks, such as construction material handling or utility maintenance, maximizing productivity without compromising safety.

- Precision Control: Achieve accurate positioning with smooth extension and retraction. The cylinder’s advanced hydraulic system enables seamless operation, allowing operators to maneuver aerial platforms with pinpoint precision, ideal for tasks like telecommunications installations or facility repairs requiring exact placement.

- Durable Materials: Constructed from high-grade steel, this hydraulic cylinder for aerial work platform withstands harsh environments, including extreme weather and corrosive conditions. Its rugged build ensures long-term reliability, reducing replacement costs for industries like municipal services and construction.

- Leak-Proof Seals: Equipped with advanced seals, this cylinder prevents fluid leaks, minimizing maintenance downtime and costs. The reliable lifting cylinder for aerial work vehicles ensures consistent performance, even under high pressure, making it a low-maintenance solution for busy operations.

- Customizable Design: Available in various stroke lengths and mounting configurations, this custom lifting cylinder for aerial platform meets diverse equipment specifications. Tailored to fit leading articulated and telescopic boom lifts, it offers flexibility for unique project requirements in maintenance or infrastructure applications.

- Easy Maintenance: Designed with accessible components, this cylinder simplifies inspections and repairs. Technicians can quickly check seals, clean rods, or replace parts, reducing downtime. The low-maintenance hydraulic cylinder for boom lift keeps your aerial platforms operational with minimal effort.

- ISO-Certified Quality: Manufactured to meet international ISO 9001, 14001, and 45001 standards, this cylinder guarantees safety and performance. Huachang’s rigorous quality control ensures each lifting cylinder for scissor type aerial work vehicles delivers unmatched reliability, trusted by global aerial platform operators.

How Does The Load Capacity Of A Lifting Cylinder Impact Safety In Aerial Work Applications?

Certainly! Here’s an expanded and optimized version of each point regarding how the load capacity of a lifting cylinder impacts safety in aerial work applications:

Overload Prevention:

A lifting cylinder designed with an appropriate load capacity is essential for safely lifting and supporting intended weights. When a cylinder is overloaded, it risks catastrophic failure, which can result in severe accidents, injuries, or damage to both the equipment and the surrounding area. Ensuring that the cylinder’s specifications match the expected load is crucial to maintaining a safe working environment and avoiding costly incidents.

Stability:

The load capacity of a lifting cylinder significantly contributes to the stability of aerial platforms. When the cylinder can adequately support the weight being lifted, it helps maintain the platform’s balance, preventing it from tipping or swaying. This stability is vital, especially when working at heights, as it minimizes the risk of falls or accidents that could endanger operators and bystanders.

Controlled Operations:

A cylinder with sufficient load capacity enables smoother lifting and lowering operations, allowing for precise movements. This control is crucial in preventing jerky or abrupt motions that can lead to accidents, equipment damage, or loss of load. By ensuring that the lifting cylinder can handle the weight safely, operators can perform tasks with greater confidence and accuracy, enhancing overall safety during operations.

Longevity and Reliability:

Lifting cylinders that operate within their specified load capacity experience reduced stress and wear, contributing to their longevity and reliability. Over time, consistent operation within safe limits helps maintain the integrity of the cylinder, leading to fewer breakdowns and maintenance needs. A reliable lifting cylinder is essential for safety, as it minimizes the chances of unexpected failures during critical lifting tasks, ensuring smooth operations.

Compliance with Regulations:

Adhering to load capacity requirements is often a legal necessity, as many safety standards and regulations outline specific load limits for lifting equipment. Ensuring that the lifting cylinder meets or exceeds these regulatory requirements not only promotes safe operations but also protects businesses from legal liabilities and penalties. Compliance fosters a culture of safety within the organization, reinforcing the importance of using equipment that is both reliable and compliant with industry standards.

In conclusion, the load capacity of a lifting cylinder is integral to safety in aerial work applications, influencing overload prevention, stability, operational control, equipment longevity, and regulatory compliance. By prioritizing these factors, operators can create a safer working environment and enhance overall operational efficiency.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Zapraszamy na wycieczkę po naszej fabryce VR:

Wybierz się na wycieczkę po naszej fabryce VR z następującymi elementami

Jak działa siłownik hydrauliczny wózka widłowego?

Siłownik hydrauliczny Zastosowanie: