Main And Auxiliary Lifting Spring Cylinders For No Tillage Machines

Som en av produsentene, leverandørene og eksportørene av mekaniske produkter tilbyr vi hydrauliske sylindere og mange andre produkter.

Ta kontakt med oss for mer informasjon.

Post:sales@hydraulic-cylinders.net

Produsent, leverandør og eksportør av hydrauliske sylindere.

Main And Auxiliary Lifting Spring Cylinders For No Tillage Machines

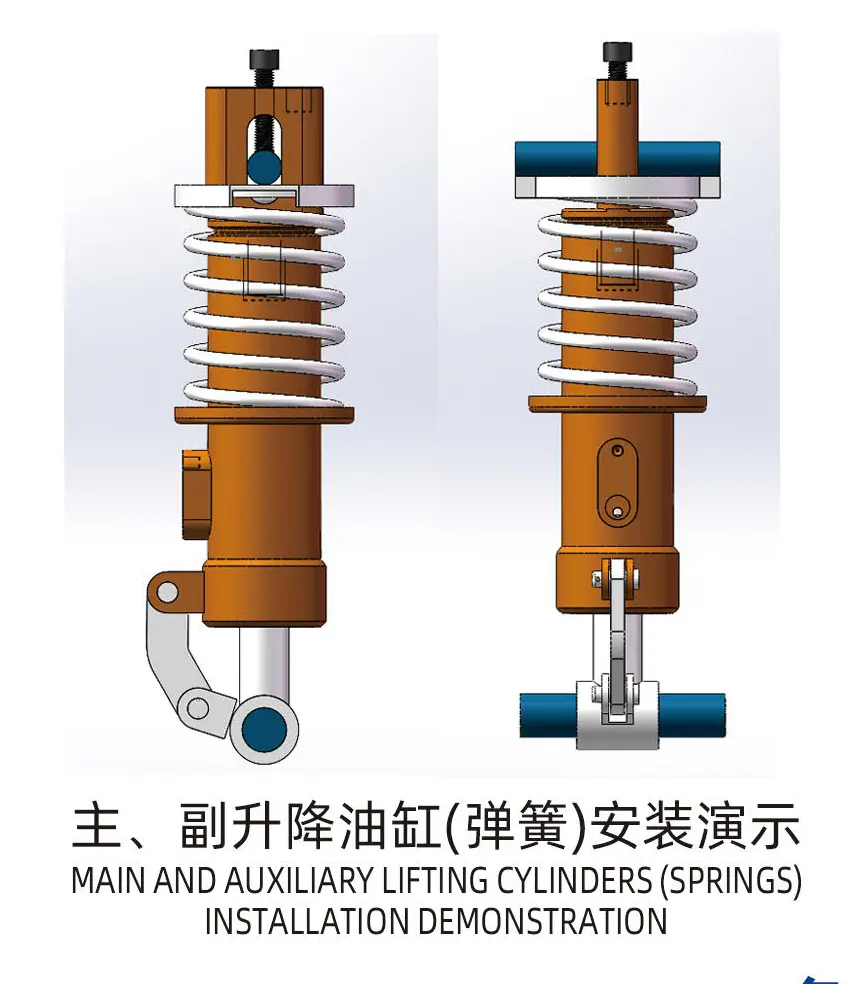

Main and auxiliary lifting spring cylinders are essential components of no-tillage machines, skillfully designed to enhance both functionality and efficiency. These hydraulic cylinders enable precise lifting and lowering of equipment, ensuring seamless operation during critical agricultural tasks. With their robust construction and advanced engineering, they are pivotal in modern farming, contributing to better soil management and increased crop yields.

These lifting spring cylinders are integral to the effective performance of no-tillage machines. Their impressive load capacity, durable design, and smooth operation significantly boost agricultural efficiency. When farmers adhere to proper usage and maintenance practices, they can count on these cylinders to perform reliably, leading to enhanced productivity and successful farming results. Investing in high-quality lifting spring cylinders is a smart choice for any forward-thinking agricultural operation.

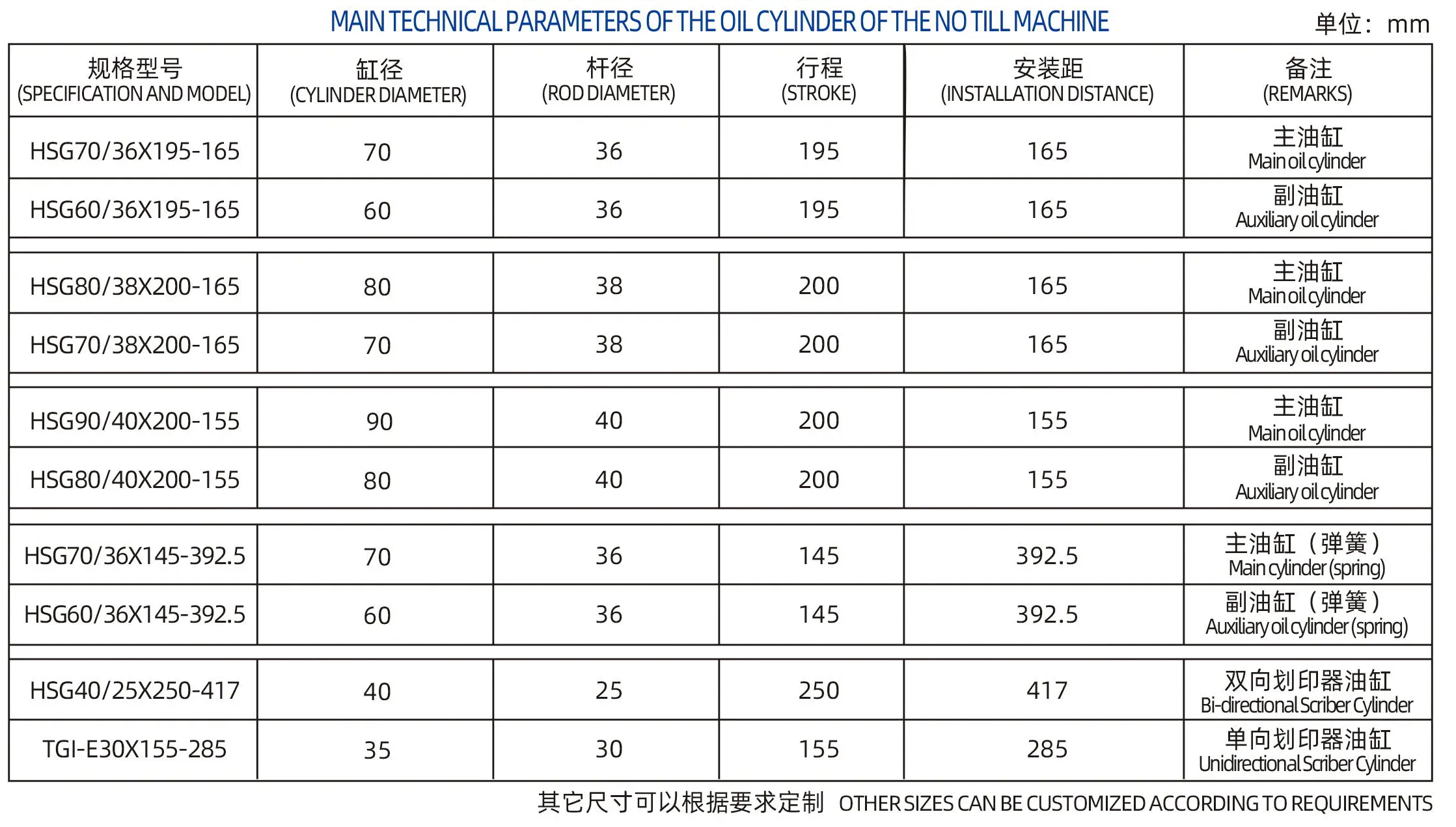

Main And Auxiliary Lifting Spring Cylinders For No Tillage Machines Machines Parameter:

Main And Auxiliary Lifting Spring Cylinders For No Tillage Machines Application:

Main And Auxiliary Lifting Spring Cylinders For No Tillage Machines Key Features:

Exceptional Load Capacity

These lifting spring cylinders are engineered to handle substantial weights, providing the necessary force to lift heavy agricultural implements effortlessly. This impressive load capacity allows farmers to approach demanding tasks with confidence, enhancing efficiency and enabling the management of larger fields and more complex operations.

Robust Versatility

Designed to be compatible with a wide range of no-tillage machines, these cylinders offer remarkable versatility for various agricultural applications. Their ability to integrate seamlessly with existing equipment means farmers can upgrade their machinery without the hassle of extensive modifications. This adaptability fosters tailored solutions that meet specific operational needs, ultimately boosting overall productivity.

Smooth and Efficient Operation

The advanced hydraulic design of these cylinders minimizes friction, resulting in smooth and controlled lifting and lowering actions. This feature not only enhances operational efficiency but also allows farmers to perform their tasks with greater precision. The seamless operation contributes to improved workflow, better soil management, and optimal crop placement.

Durable Construction

Crafted from high-quality materials, these lifting spring cylinders are built to endure the challenges of harsh farming environments. Their robust construction resists wear and tear, ensuring long-lasting performance even under demanding conditions. This durability reduces the frequency of replacements, allowing farmers to concentrate on their work rather than equipment maintenance.

Effortless Installation

Designed with user-friendliness in mind, these lifting spring cylinders enable straightforward installation, minimizing downtime during setup. Farmers can quickly and efficiently integrate these cylinders into their operations, getting back to work without delays. This ease of installation helps optimize productivity right from the start.

By opting for these high-performance lifting spring cylinders, farmers can significantly enhance their no-tillage machines, ensuring reliable operation and improved agricultural efficiency. Investing in quality components leads to a more productive and successful farming experience, paving the way for a brighter agricultural future.

Main And Auxiliary Lifting Spring Cylinders For No Tillage Machines Applicable Model:

Main And Auxiliary Lifting Spring Cylinders For No Tillage Machines Usage Method:

To maximize the effectiveness of main and auxiliary lifting spring cylinders, consider these essential steps:

1. Installation

Start by installing the lifting spring cylinders in strict accordance with the manufacturer’s guidelines. Proper installation is critical for achieving optimal performance. Take your time to secure all connections to prevent leaks, which can cause inefficiencies and potential damage. Ensure the cylinders are aligned correctly, allowing them to operate smoothly within the no-tillage machine. A well-installed cylinder not only boosts functionality but also enhances the overall safety of the equipment.

2. Hydraulic System Inspection

Before beginning any operation, conduct a thorough inspection of the hydraulic system. Check the hydraulic fluid levels to confirm they fall within the recommended range, as insufficient fluid can impede performance and lead to system failures. Examine hoses and fittings for any signs of wear, cracks, or leaks. Maintaining proper hydraulic pressure is essential for effective lifting and ensures the machine operates at its best. Regular inspections are advisable to catch potential issues early.

3. Engagement

After installation and inspection, activate the hydraulic system to lift or lower the components of the no-tillage machine. Use the control levers thoughtfully, allowing for gradual and precise movements. This careful approach enables accurate adjustments based on varying field conditions, such as changes in terrain or crop height. Smooth engagement of the hydraulic system not only enhances efficiency but also improves overall soil management practices.

4. Performance Monitoring

While operating, keep a close eye on the performance of the lifting cylinders. Regularly listen for any unusual sounds, such as grinding or excessive noise, and watch for signs of resistance during lifting and lowering. These indicators may point to maintenance needs or mechanical issues. Detecting problems early allows for timely repairs, helping to avoid costly downtime and ensuring the machinery remains in optimal working condition. By staying vigilant, farmers can extend the lifespan and reliability of their lifting spring cylinders.

By following these steps, users can ensure their main and auxiliary lifting spring cylinders function efficiently, leading to enhanced productivity and successful agricultural results.

Test Equipment:

- 1: Salt Spray Test Chamber

- 2: Chemical Analysis

- 3: Tensile Testing Machine

- 4: Rockwell Hardness Tester

- 5: Cleanliness Testing Machine

- 6: TH110 Rebound Hardness Tester

- 7: Coating Thickness Gauge

- 8: Pendulum Impact Test

Our company considers quality to be the foundation of our success. To uphold this commitment, we have invested in cutting-edge domestic testing and laboratory equipment, supported by a team of highly skilled professionals in science and technology.

We maintain a rigorous quality management system that complies with industry standards, ensuring that every batch of products we produce meets the highest quality criteria. By standardizing our operations and continuously monitoring our processes, we ensure that our customers receive only the best.

This steadfast dedication to quality not only enhances the reliability of our products but also builds trust and satisfaction among our clients. We believe that by prioritizing excellence in every facet of our production, we contribute to the success of our partners and the industry as a whole. Together, we aim for innovation and quality that endure over time.

Hydraulic Cylinder Production Site:

Our company is a leading manufacturer specializing in hydraulic cylinders, backed by our own independent research, development, and design capabilities. With a state-of-the-art facility housing over 170 general machine tools, CNC machines, machining centers, welding equipment, and specialized testing and inspection tools, we are well-equipped to meet diverse industrial demands.

Through years of accumulated technological expertise and process refinement, we have established a mature production process that seamlessly integrates R&D with manufacturing. This integration has become our core competitive advantage, allowing us to design and produce a wide range of hydraulic cylinders customized to meet specific customer requirements.

Our products are widely used across various sectors, including agricultural machinery, construction equipment, vehicles, road engineering, and specialized machinery. We proudly support numerous OEMs, including Bonong Xingda, Bojin Hummer, Jilin Ruifeng, Debang Dawei, Shandong Yineng Heavy Industry, Tai’an Modern Heavy Industry, and Shifeng Group, among others.

We are dedicated to providing exceptional service through a strong quality policy that prioritizes continuous innovation in research and development, management, quality control, and customer service. Our commitment to quality has been recognized with ISO/TS16949 certification, which ensures that we not only meet but consistently exceed our clients’ expectations.

Looking ahead, we will continue to advance our technology and broaden our capabilities, always aiming to deliver the highest quality products and services to our customers. Together, we are forging a legacy of excellence in the hydraulic cylinder industry.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: