HSG Engineering Hydraulic Cylinder

Som en av produsentene, leverandørene og eksportørene av mekaniske produkter tilbyr vi hydrauliske sylindere og mange andre produkter.

Ta kontakt med oss for mer informasjon.

Post:sales@hydraulic-cylinders.net

Produsent, leverandør og eksportør av hydrauliske sylindere.

HSG Engineering Hydraulic Cylinder

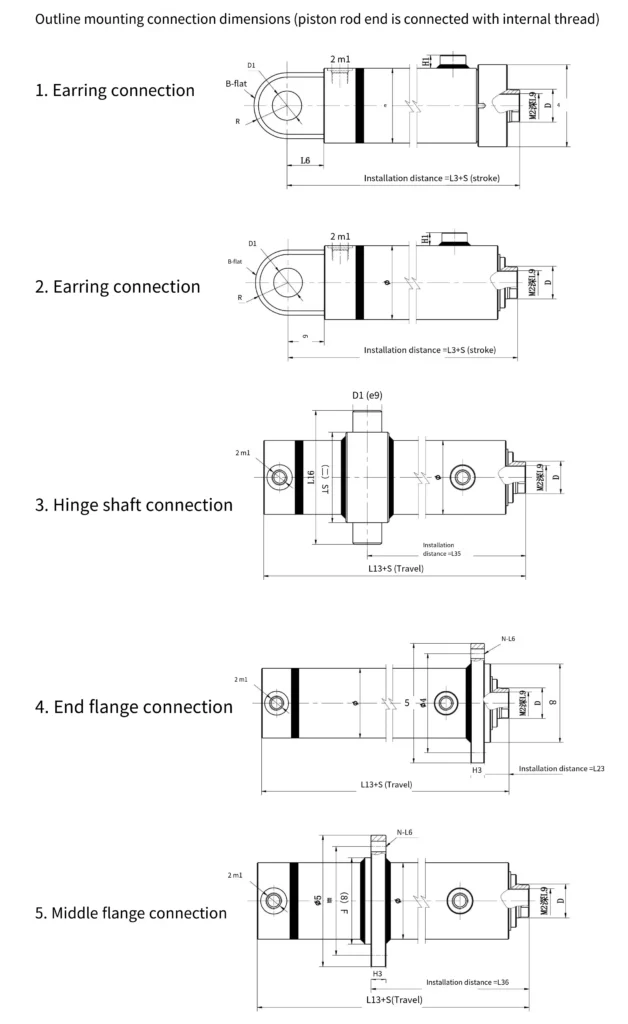

HSG series engineering hydraulic cylinder is a double-acting piston rod hydraulic cylinder. Installation mode adopts earring type. According to the connection between the cylinder head and the cylinder block, there are three kinds of external thread connection, internal card critical connection, and flange connection. Engineering hydraulic cylinder is mainly used in construction, lifting, mining, and other hydraulic systems.

Front And Back Earring Installation Features:

The installation of the tail single lifting ring is suitable for the end part to move along the same moving plane curve during the working process of the piston rod. Both sides of the piston rod do not exceed 3°, with the actual meeting the plane path conditions or structural design requirements of the single earring installation conditions. At this time, the tail and rod end spherical bearings can be installed, but attention should be paid to the pressure load allowed by the installation of spherical bearings.

HSG Engineering Hydraulic Cylinder Scope Of Application:

Primarily used in construction, heavy lifting, mining, and other hydraulic systems in the engineering hydraulic cylinder, but not limited to the above aspects – pressure class 16Mpa.

When the force of the cylinder is relatively large (such as 20 tons) and the stroke is rather long (such as 2 meters), the pull rod cylinder is unsuitable for use due to the force limitation of the screw, and the engineering cylinder can be used instead.

Due to the engineering hydraulic cylinder’s enormous pressure and manufacturing process, its material cost and processing costs are higher than those of the tie rod cylinder.

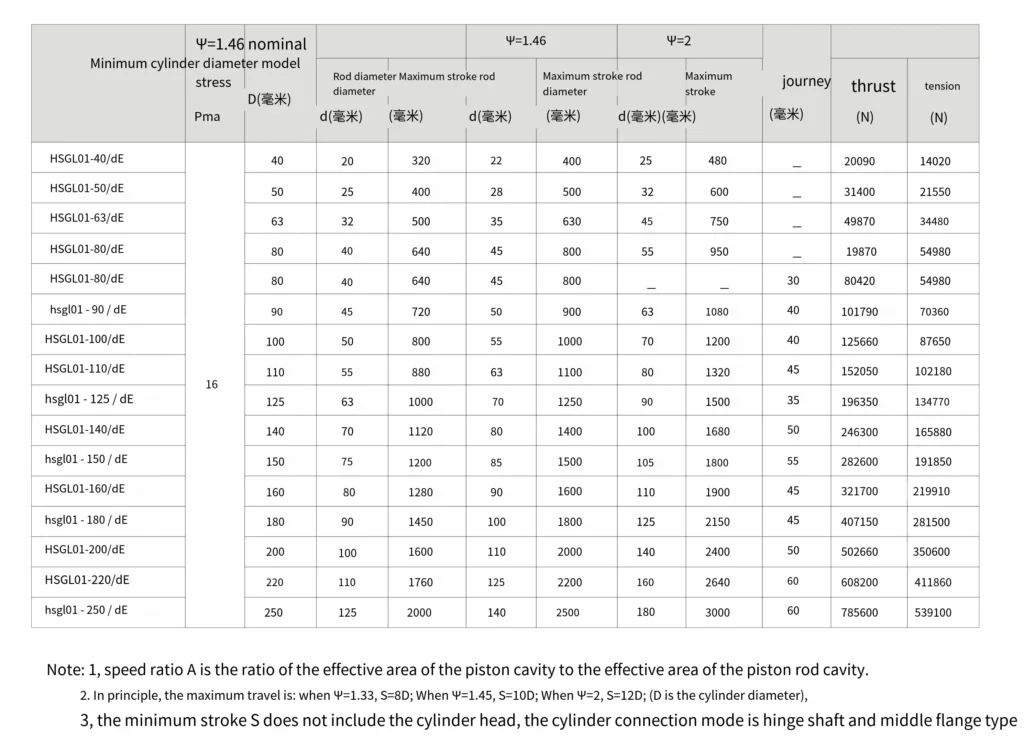

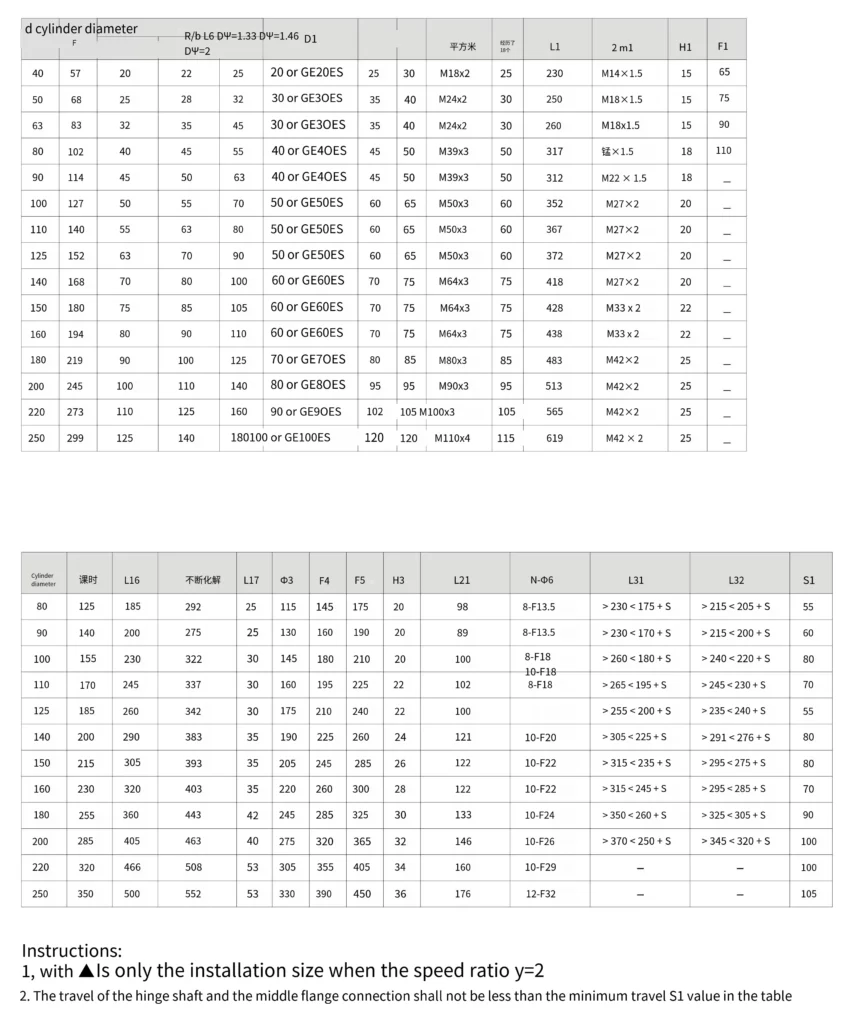

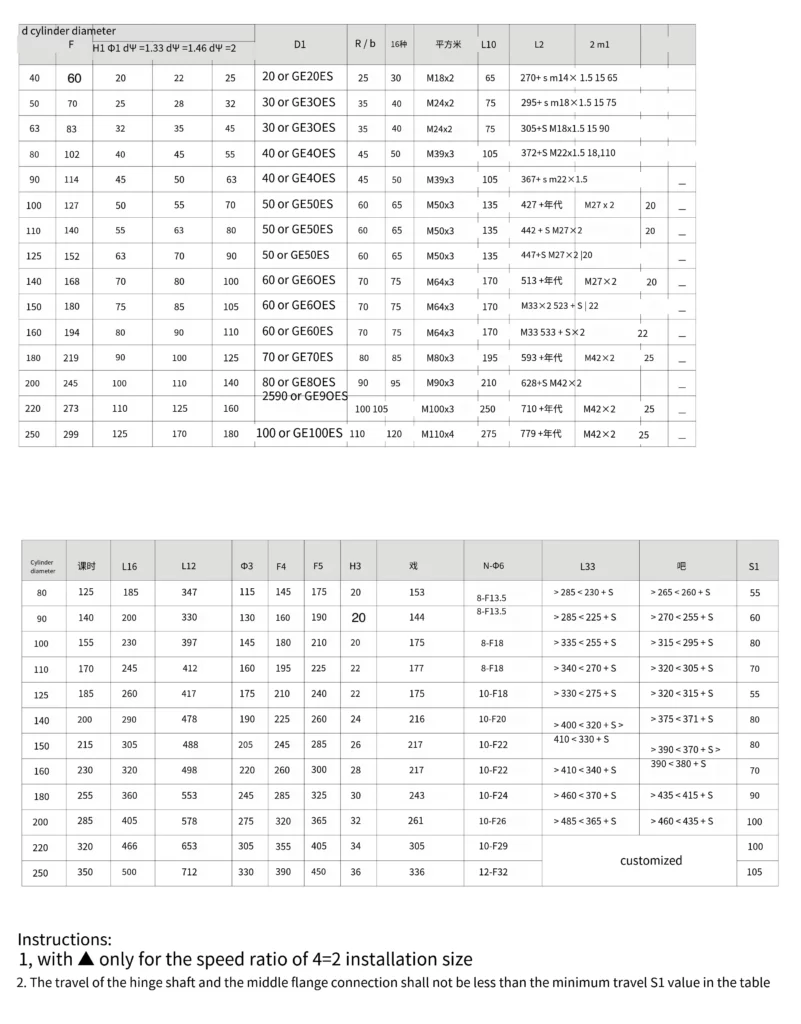

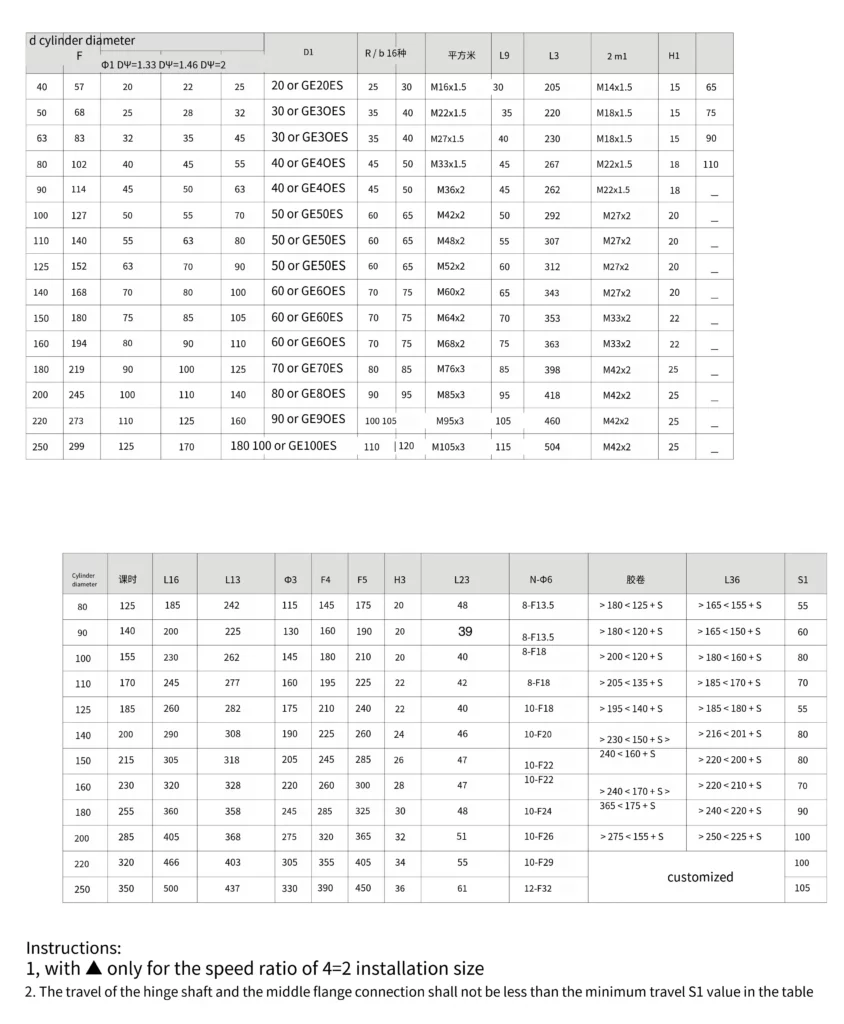

HSG Engineering Hydraulic Cylinder Parameter:

Model Selection Of HSG Engineering Hydraulic Cylinder:

HG-L-01-D/DX100-E2501

HG-Double-acting hydraulic cylinder

L-cylinder head connection mode: L= thread type (cylinder diameter <080); K= clamp type (cylinder diameter >080)

01- Design No.

D/d cylinder diameter mm/ piston rod mm

100- hydraulic cylinder stroke

E-pressure grade: E=16MPa G=21MPa

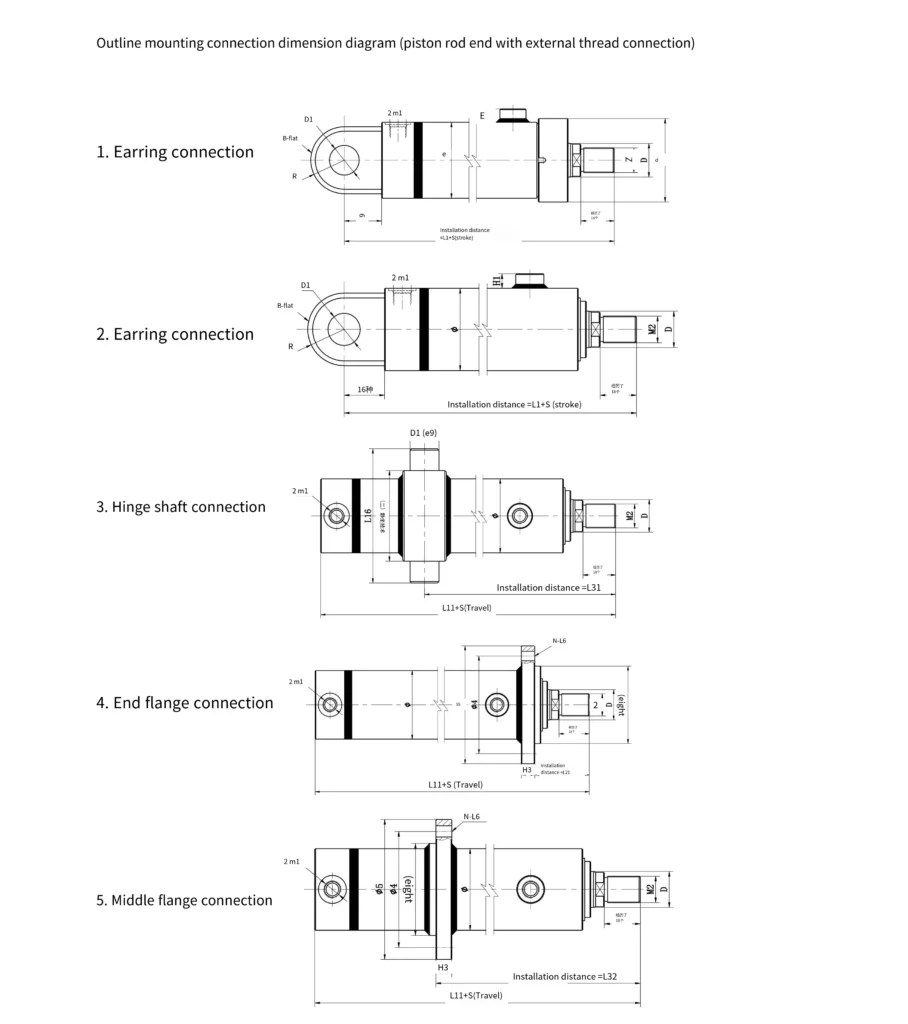

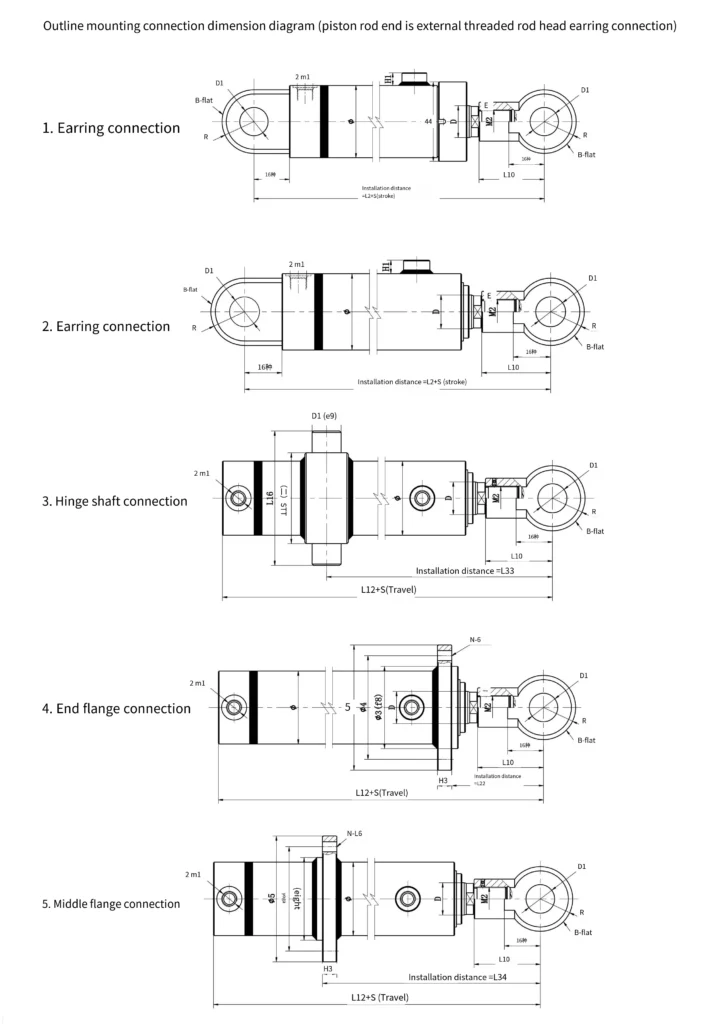

2- cylinder head, cylinder connection :

1= cylinder head earring with bushing; 2= cylinder head earring with joint bearing; 3= hinge shaft (for cylinder diameter >Φ80 card key connection); 4= end flange (for cylinder diameter >Φ80 card key connection) 5= middle flange (for cylinder diameter >Φ80 card key connection)

5- piston rod end connection:

1= rod end external thread; 2= rod end internal thread (cylinder diameter >Φ63); 3= rod end external thread rod head earring with bushing; 4= rod end internal thread rod head earring with bushing (cylinder diameter >Φ63); 5= rod end external thread rod head earring with joint bearing; 6= rod end internal thread rod head earring with joint bearing (cylinder diameter >Φ63); 7= integral piston rod earring with bushing (only for cylinder diameter =Φ40, diameter 50); 8= integral piston rod earring with joint bearing (only for cylinder diameter = 40, with 50)

0- buffer part:

0= no buffer; 1= buffer at both ends; 2= cylinder head end with buffer; 3= rod head end with buffer 1- oil port connection mode:1= metric internal thread; 2= English internal thread

L1- piston rod end connection mode: L1= rod end external thread; L2= rod end internal thread

0- working medium: 0= oil, hydraulic oil; W= High water base (emulsion). Note: Those marked with A in the model description are treated as non-standard.

HSG Engineering Hydraulic Cylinder Technical Parameter:

You can use the following model notation to select the product you want. Model example: HG-L-50/40 *100-2501

HSG series engineering hydraulic cylinder basic parameters, including cylinder diameter, rod diameter, and maximum stroke.

1, the speed ratio is the ratio of the effective area of the piston cavity to the adequate size of the piston rod cavity.

2, the maximum stroke is in principle: when the speed ratio =1.33, S=8D; When the ratio =1.45, S=10D; When the balance is equal to 2, S is similar to 12D

How To Find Seal Kit For Hydraulic Cylinder?

Finding the correct seal kit for a hydraulic cylinder is crucial to ensure proper fit, functionality, and performance. Here are some steps to help you find the appropriate seal kit:

- Identify the Cylinder Manufacturer and Model:

- Determine the manufacturer of the hydraulic cylinder. This information is often stamped or engraved on the cylinder body.

- If possible, note down the model number or any other identifying markings on the cylinder.

- Gather Cylinder Specifications:

- Measure the dimensions of the cylinder, including the bore diameter, rod diameter, and stroke length.

- Note any specific features or configurations unique to the cylinder, such as flanges, ports, or mounting styles.

- Research the Manufacturer’s Resources:

- Visit the manufacturer’s website or contact customer support to inquire about available seal kits for your specific cylinder model.

- Provide the manufacturer with the cylinder specifications and any identifying information you have gathered.

- Explore Online Hydraulic Seal Suppliers:

- Search for reputable online hydraulic seal suppliers or distributors.

- Utilize search filters or navigation menus on their websites to narrow down the selection based on cylinder specifications or manufacturer.

- Utilize Seal Kit Cross-Reference Tools:

- Some seal kit suppliers offer cross-reference tools or databases that help match cylinder models with compatible seal kits.

- Enter the cylinder manufacturer, model, or other specifications into the cross-reference tool to find suitable seal kits.

- Consult Hydraulic System Maintenance Manuals:

- Check if the equipment or machinery that uses the hydraulic cylinder has a maintenance manual.

- The manual may include information on recommended seal kits or part numbers.

- Seek Assistance from Hydraulic Experts:

- Reach out to hydraulic system specialists, maintenance professionals, or engineers with expertise in hydraulic systems.

- They can guide and recommend finding the correct seal kit for your hydraulic cylinder.

- Consider Custom Seal Kits:

- If you cannot find a seal kit specifically designed for your cylinder model, consider contacting a manufacturer or supplier that offers custom seal kits.

- Provide accurate measurements and cylinder specifications for a seal kit tailored to your requirements.

- Purchase and Install the Seal Kit:

- Once you have identified the appropriate seal kit, place an order with the supplier or manufacturer.

- Follow the installation instructions with the seal kit carefully to ensure proper installation and optimal performance.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best engineering hydraulic cylinder manufacturers. We can offer comprehensive engineering hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: