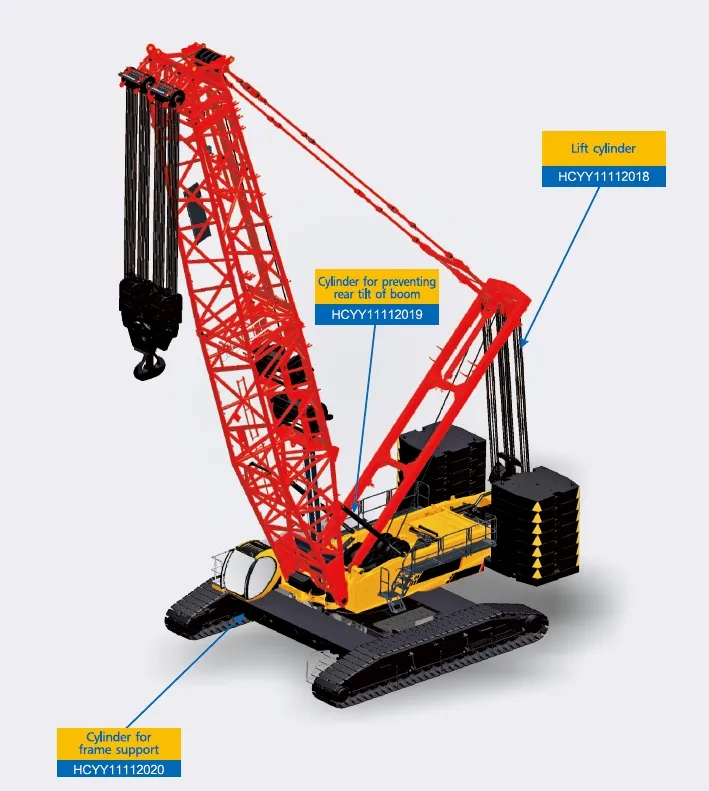

Lift Cylinder For Crawler Crane

Som en av produsentene, leverandørene og eksportørene av mekaniske produkter tilbyr vi hydrauliske sylindere og mange andre produkter.

Ta kontakt med oss for mer informasjon.

Post:sales@hydraulic-cylinders.net

Produsent, leverandør og eksportør av hydrauliske sylindere.

Lift Cylinder For Crawler Crane

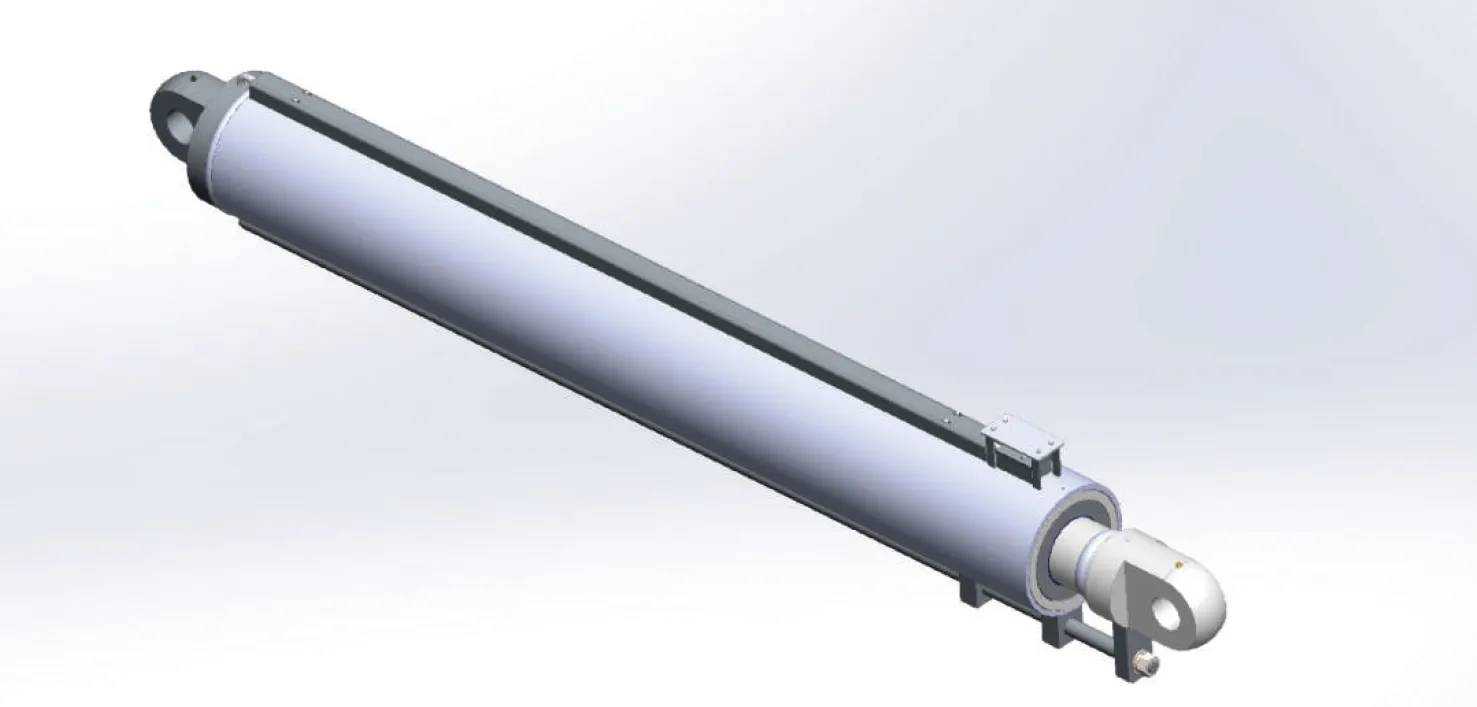

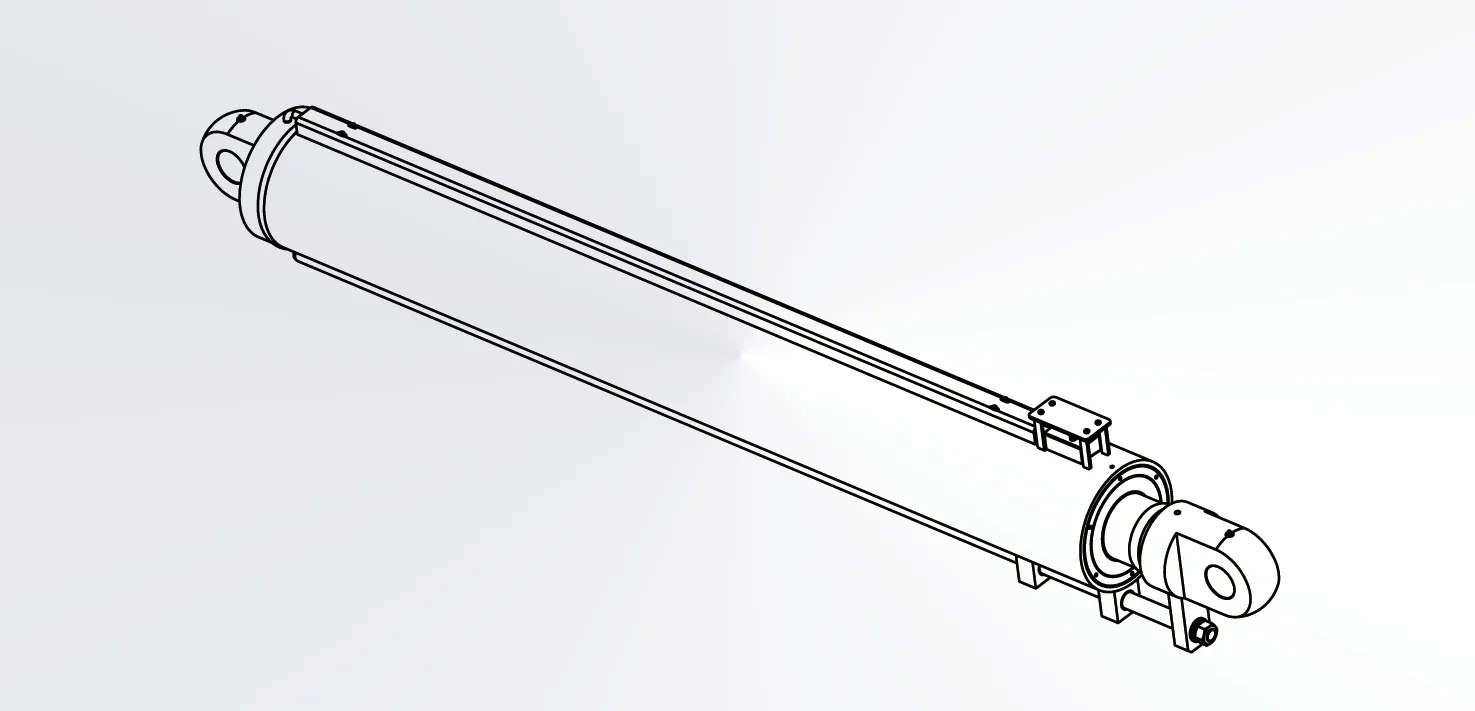

Our Lift Cylinders for Crawler Cranes are designed to deliver powerful and reliable lifting performance for heavy-duty applications. Engineered specifically for crawler cranes, these hydraulic cylinders provide the force needed to elevate crane arms (booms) with precision, supporting loads up to 590 tons in demanding environments such as construction sites, bridge building, and mining operations. Constructed with high-strength alloy steel and featuring advanced sealing systems, our lift cylinders ensure durability and leak-free operation, even under extreme dynamic loads and harsh conditions.

With a pressure rating of up to 35 MPa and optional corrosion-resistant coatings, they are built for long-term reliability in rugged terrains. Whether you’re hoisting steel beams or positioning heavy equipment, our lift cylinders for crawler cranes guarantee safety, efficiency, and unmatched performance for your lifting needs.

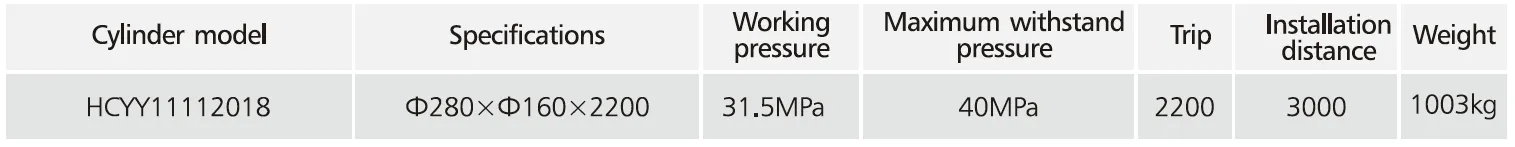

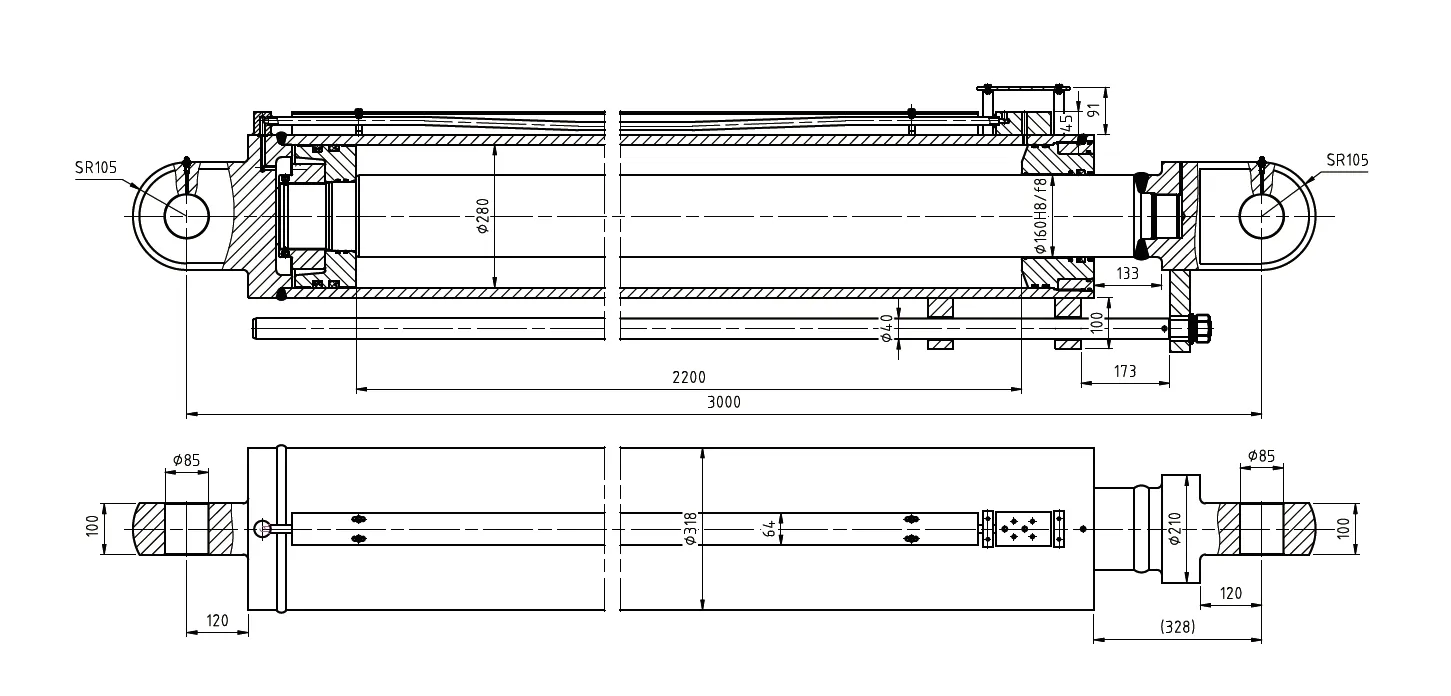

Lift Cylinder For Crawler Crane Parameter:

Cylinder Series Of Crawler Crane:

Key Features of Lift Cylinder For Crawler Crane:

High Durability

The Lift Cylinder is constructed from premium-grade materials specifically chosen for their strength and resilience. This robust design enables the cylinder to withstand harsh working conditions and heavy loads, making it an ideal choice for demanding construction environments. Users can rely on its long-lasting performance, reducing the need for frequent replacements and ensuring uninterrupted operations, even in the most challenging scenarios.

Precision Engineering

Engineered with meticulous attention to detail, the features precise manufacturing tolerances. This level of precision enables smooth operation and enhances lifting accuracy, allowing operators to confidently handle loads. Whether lifting delicate materials or heavy machinery, this cylinder ensures that each movement is controlled and reliable, minimizing the risk of accidents and improving overall efficiency.

Corrosion Resistance

To combat the effects of exposure to moisture and harsh elements, the Lift Cylinder undergoes a specialized surface treatment. This protective layer guards against rust and corrosion, significantly extending the cylinder’s lifespan. By maintaining optimal performance over time, this feature not only enhances the reliability of the cylinder but also contributes to lower maintenance costs and increased operational efficiency.

Compact Design

The compact design of the Lift Cylinder sets it apart, allowing for easy installation and seamless integration into various crawler crane models. Its space-saving dimensions enable operators to maximize the efficiency of their machinery without sacrificing power. This versatility makes it an excellent choice for projects with limited space, ensuring that heavy-lifting capabilities are never compromised.

High-Pressure Capacity

Designed to handle high hydraulic pressures, the Lift Cylinder excels in delivering efficient lifting operations. This capability ensures that the cylinder can manage substantial loads safely and effectively, providing peace of mind to operators. By prioritizing safety while maximizing performance, this cylinder supports a wide range of applications, from construction to industrial lifting tasks, making it a reliable choice for any heavy-duty operation.

What Makes The Lift Cylinder Suitable For Heavy-Duty Lifting?

Here’s an expanded explanation of why the Lift Cylinder is suitable for heavy-duty lifting:

- Exceptional Durability:

The Lift Cylinder is constructed from high-quality materials specifically chosen for their strength and resilience. This robustness allows the cylinder to withstand extreme conditions, such as heavy vibrations, shock loads, and harsh environmental factors typical in construction and industrial settings. The durability minimizes wear and tear, leading to fewer breakdowns and reduced downtime, which is critical for maintaining productivity on job sites. - High Pressure Capacity:

This lift cylinder is engineered to handle high hydraulic pressures, crucial for lifting significant weights safely and efficiently. Its design incorporates advanced engineering principles that allow it to perform under intense stress without compromising structural integrity. This high-pressure capacity ensures that the cylinder can lift heavy machinery and materials reliably, making it suitable for various applications from construction to heavy manufacturing. - Precision Engineering:

The features have state-of-the-art manufacturing tolerances that ensure precise alignment and operation. This level of precision is vital for tasks requiring delicate handling or exact positioning, as it minimizes the risk of accidents and enhances overall lifting accuracy. Operators can trust that the cylinder will perform consistently, leading to increased confidence in lifting operations and improved safety for both personnel and equipment. - Superior Corrosion Resistance:

To combat the effects of moisture, chemicals, and other corrosive elements, the undergoes a specialized surface treatment. This protective layer significantly reduces the risk of rust and corrosion, which can otherwise lead to mechanical failures. By enhancing the cylinder’s resistance to environmental factors, this feature ensures long-term reliability and performance, ultimately lowering maintenance costs and extending the lifespan of the equipment. - Compact Design:

The compact design of the Lift Cylinder allows for easy installation and integration into various crawler crane models. This space-saving feature is especially beneficial in environments with limited space, where maximizing the crane’s operational capabilities is essential. The streamlined design does not compromise lifting power, ensuring that operators can efficiently handle heavy loads without the bulkiness associated with traditional cylinders.

These enhanced features collectively make the Lift Cylinder a top choice for heavy-duty lifting applications, ensuring reliability, efficiency, and safety on the job.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: