HCYY11112014 Swing Arm Cylinder For Environmental Protection

Som en av produsentene, leverandørene og eksportørene av mekaniske produkter tilbyr vi hydrauliske sylindere og mange andre produkter.

Ta kontakt med oss for mer informasjon.

Post:sales@hydraulic-cylinders.net

Produsent, leverandør og eksportør av hydrauliske sylindere.

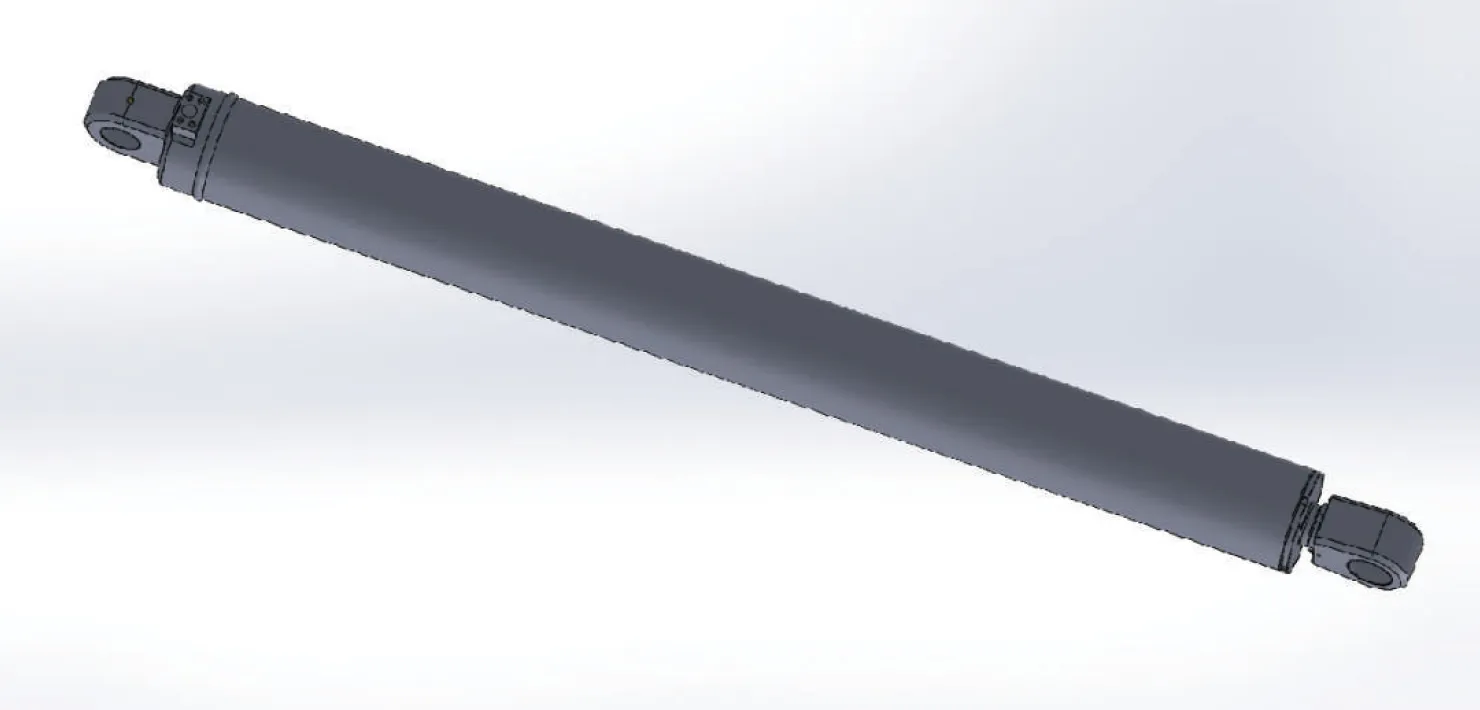

HCYY11112014 Swing Arm Cylinder For Environmental Protection

The HCYY11112014 Swing Arm Cylinder is a state-of-the-art solution that boosts operational efficiency while prioritizing environmental sustainability. This innovative product serves various industries, delivering reliable performance with minimal ecological impact.

As a significant advancement in eco-friendly technology, the HCYY11112014 Swing Arm Cylinder embodies durability and efficiency, making it the perfect choice for businesses committed to sustainability. By incorporating this product into your operations, you not only enhance productivity but also contribute to a healthier planet. Make the smart choice today by investing in the HCYY11112014 and experience the advantages of cutting-edge technology designed with environmental protection at its core.

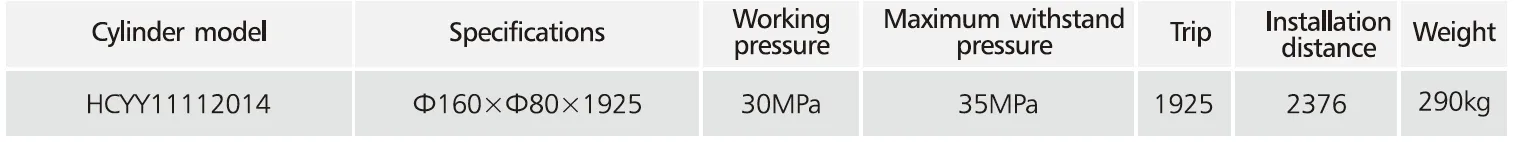

HCYY11112014 Swing Arm Cylinder For Environmental Protection Parameter:

Cylinder Series For Environmental Protection:

Key Features of the HCYY11112014 Swing Arm Cylinder For Environmental Protection:

Eco-Friendly Materials

The HCYY11112014 Swing Arm Cylinder is constructed from high-quality, recyclable, and sustainable materials. This commitment to responsible manufacturing minimizes environmental impact and supports a circular economy. By choosing this cylinder, you contribute to a future where waste is reduced and resources are maximized.

Low Energy Consumption

Designed with energy efficiency in mind, the HCYY11112014 significantly lowers operational costs. Its innovative engineering reduces energy usage, leading to decreased carbon emissions. This means that not only do you save on expenses, but you also play a vital role in combating climate change. It’s a win-win for your business and the planet.

Advanced Sealing Technology

Safety and environmental protection are paramount, so the HCYY11112014 features state-of-the-art sealing mechanisms. These advanced seals effectively prevent leaks of hazardous substances, ensuring that your operations do not compromise the surrounding ecosystem. This technology enhances safety and fosters trust among stakeholders and the community.

Durable Construction

Built to endure the most challenging conditions, the HCYY11112014 boasts exceptional durability. Its robust construction ensures a long service life, minimizing the need for frequent replacements. This durability translates to reliability, allowing your operations to run smoothly without interruptions and reducing overall maintenance costs.

Compact Design

The HCYY11112014’s innovative compact design makes it a versatile choice for various applications. Its space-saving profile allows for seamless integration into existing systems without sacrificing performance. This adaptability enables you to optimize your workspace, maximizing efficiency and productivity in your operations.

By choosing the HCYY11112014 Swing Arm Cylinder, you embrace a product that embodies sustainability, efficiency, and innovation. Experience the difference that environmentally conscious engineering can make for your business and the future of our planet.

What Makes The Hcyy11112014 Swing Arm Cylinder Eco-Friendly?

The HCYY11112014 Swing Arm Cylinder stands out as an eco-friendly choice for several compelling reasons:

1. Sustainable Materials

Crafted from recyclable and sustainable materials, this cylinder reflects a commitment to responsible manufacturing. By choosing this product, you support a circular economy that prioritizes resource conservation and reduces waste.

2. Energy Efficiency

Designed with low energy consumption, the HCYY11112014 significantly cuts operational costs. Its energy-efficient technology saves you money and lowers carbon emissions, playing a crucial role in the fight against climate change. This means you can enhance productivity while being kind to the planet.

3. Advanced Sealing Technology

Safety is paramount, and the HCYY11112014 excels in this area. Its state-of-the-art sealing mechanisms effectively prevent leaks of hazardous substances, safeguarding the environment and ensuring compliance with safety standards. This technology fosters trust among stakeholders and demonstrates a commitment to environmental stewardship.

4. Exceptional Durability

Built to withstand harsh conditions, the HCYY11112014 offers a long service life. This durability reduces the need for frequent replacements, minimizing waste and contributing to a more sustainable operational model. With this cylinder, you benefit from reliability and peace of mind.

5. Space-Saving Design

Its compact design allows for easy integration into existing systems without sacrificing performance. This adaptability optimizes your workspace and enhances overall efficiency, making it a versatile solution for various applications.

In summary, the HCYY11112014 Swing Arm Cylinder is more than just a functional component; it’s a forward-thinking investment in sustainability. By choosing this eco-friendly option, you’re making a positive impact on both your operations and the environment, paving the way for a greener future.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: