HCYY11112006 Lifting Cylinder For Aerial Work Vehicles

Som en av produsentene, leverandørene og eksportørene av mekaniske produkter tilbyr vi hydrauliske sylindere og mange andre produkter.

Ta kontakt med oss for mer informasjon.

Post:sales@hydraulic-cylinders.net

Produsent, leverandør og eksportør av hydrauliske sylindere.

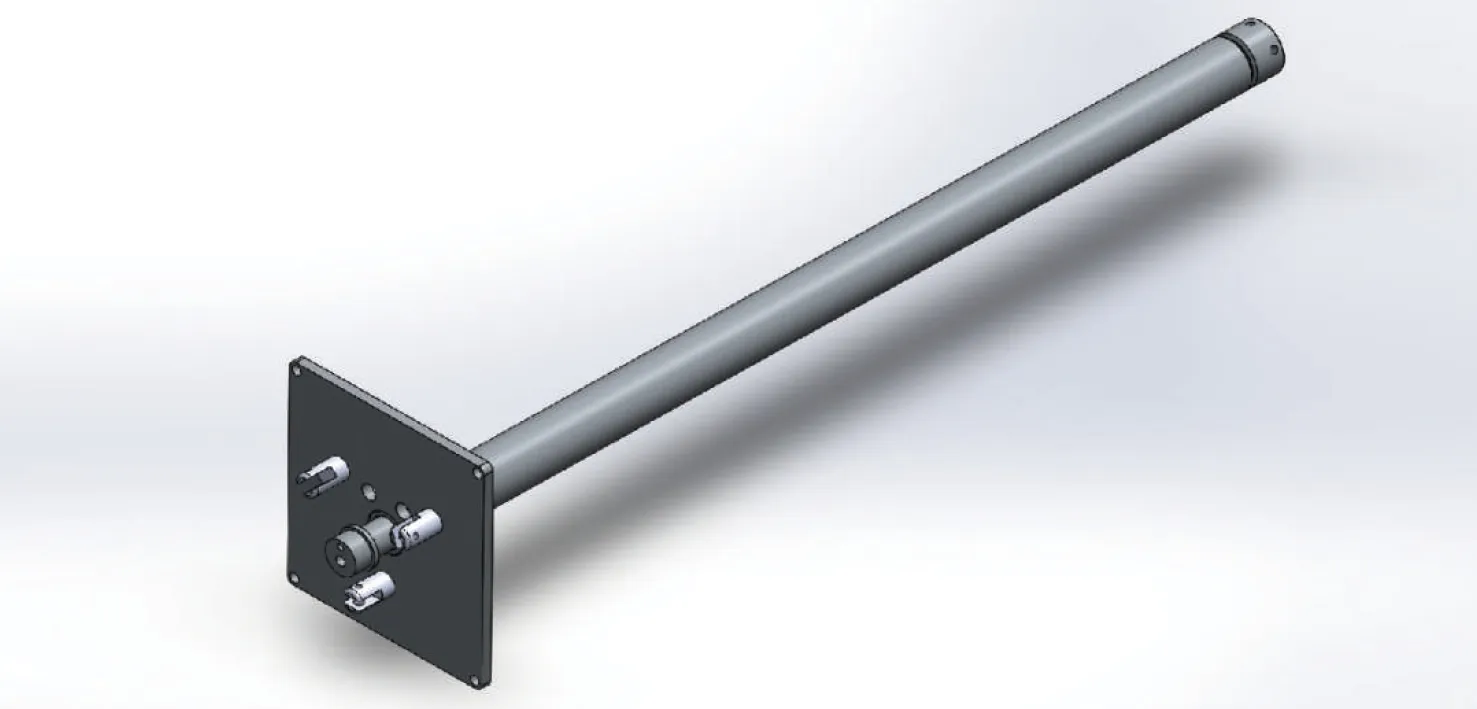

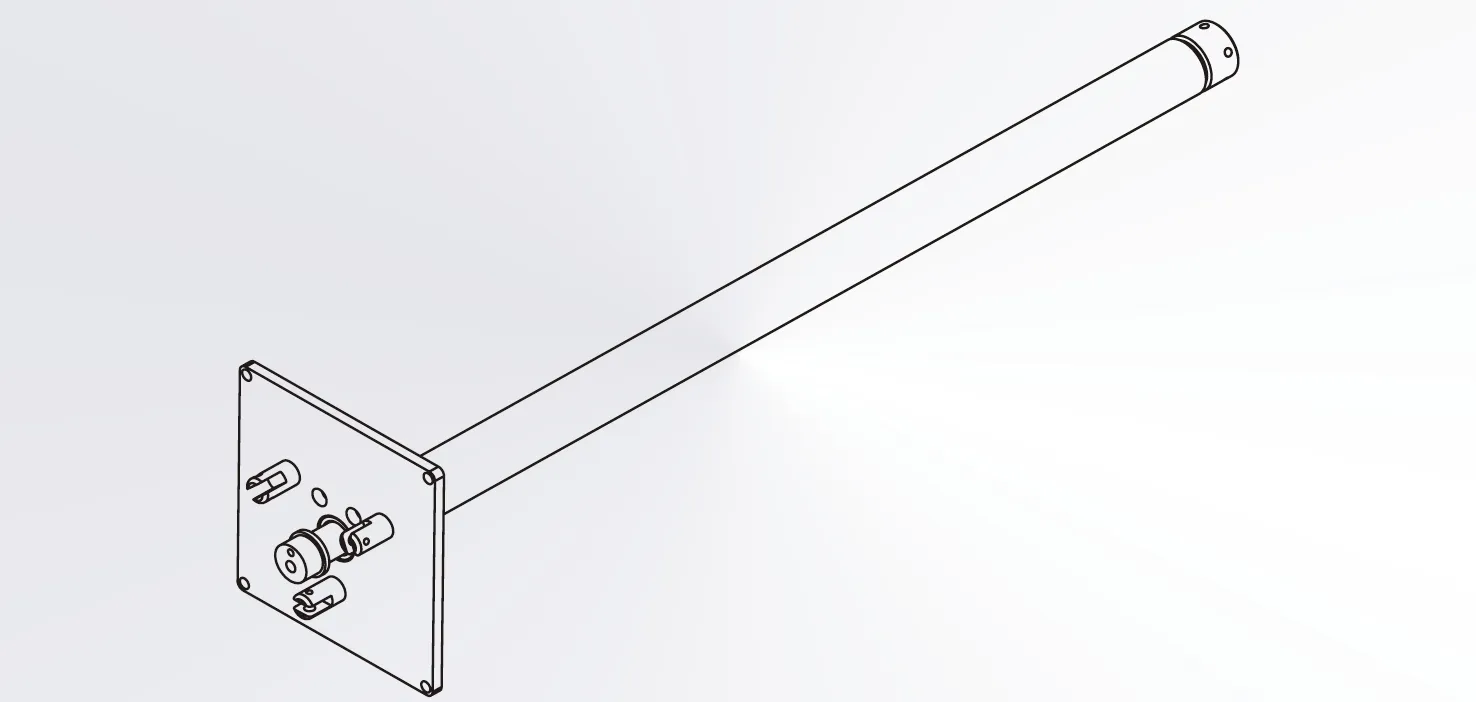

HCYY11112006 Lifting Cylinder For Aerial Work Vehicles

The HCYY11112006 Lifting Cylinder is a vital component for aerial work vehicles, engineered to deliver reliable lifting power across a range of applications. Designed with a focus on performance and safety, this cylinder empowers operators to carry out tasks at height with confidence and efficiency.

Combining exceptional durability, precision, and broad compatibility, the HCYY11112006 is essential for any aerial work setup. Its impressive load capacity and corrosion-resistant design significantly enhance safety and operational efficiency. By adhering to proper usage and maintenance guidelines, operators can optimize the performance and extend the lifespan of this critical equipment. Elevate your aerial operations with the assurance of having a dependable lifting solution at your fingertips.

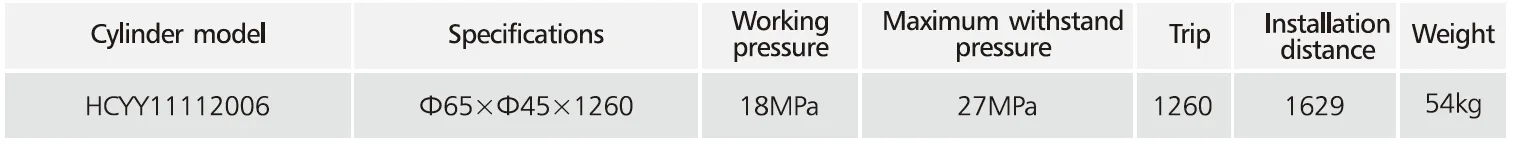

HCYY11112006 Lifting Cylinder For Aerial Work Vehicles Parameter:

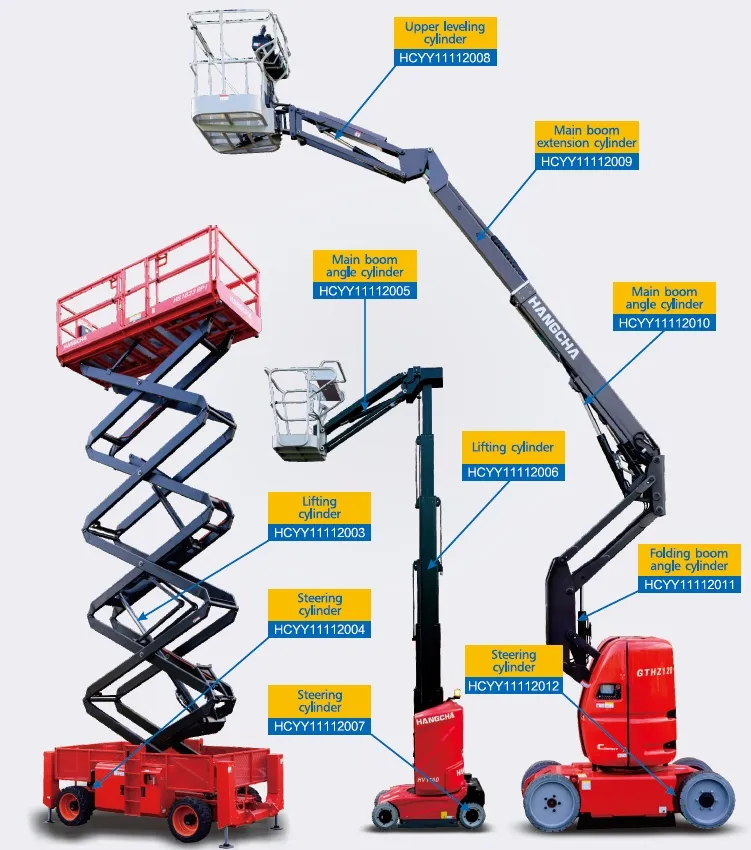

Cylinder Series For Aerial Work Vehicles:

Key Features of HCYY11112006 Lifting Cylinder For Aerial Work Vehicles:

High Load Capacity

The HCYY11112006 lifting cylinder boasts an impressive load capacity, expertly engineered to support substantial weights. This capability makes it ideal for demanding aerial applications, where reliability and strength are paramount. Whether lifting heavy equipment or personnel, this cylinder ensures safe and efficient operations, giving operators peace of mind as they work at height.

Durable Construction

Crafted from premium-grade materials, the HCYY11112006 lifting cylinder is built to endure harsh environments and heavy usage. Its robust construction minimizes wear and tear, resulting in a long lifespan that reduces the frequency of replacements. This durability guarantees that the cylinder maintains peak performance over time, even in the most challenging conditions, thereby enhancing the overall reliability of your aerial work vehicle.

Precision Engineering

Engineered for seamless and dependable operation, the HCYY11112006 lifting cylinder features advanced precision engineering. This design provides excellent responsiveness, allowing for smooth adjustments during operation. Enhanced efficiency translates to quicker lifting times, enabling operators to complete tasks more effectively. The cylinder’s precise performance helps maintain stability and safety, crucial for aerial work.

Corrosion Resistance

Equipped with advanced protective coatings, the HCYY11112006 lifting cylinder effectively resists rust and corrosion. This feature is especially beneficial in outdoor and challenging environments where moisture and harsh weather conditions can lead to deterioration. By safeguarding against corrosion, this cylinder not only prolongs its service life but also ensures that it consistently performs at optimal levels, reducing maintenance costs over time.

Compatibility

The HCYY11112006 lifting cylinder is designed to be compatible with a wide range of aerial work vehicles, making it a versatile solution for various manufacturers and models. This adaptability simplifies inventory management for fleet operators, as a single cylinder can be used across multiple equipment types. The ease of compatibility allows for seamless integration into existing systems, maximizing operational efficiency and minimizing downtime during replacements.

What Maintenance Practices Are Recommended For The HCYY11112006 Lifting Cylinder To Ensure Optimal Performance?

To ensure optimal performance of the HCYY11112006 lifting cylinder, the following maintenance practices are recommended:

Regular Inspections

Conduct routine inspections of the cylinder for any signs of wear, damage, or leaks. Check seals, hoses, and fittings for integrity. Early detection of issues can prevent more significant problems and ensure safe operation.

Cleaning

Keep the cylinder clean and free from dirt, debris, and corrosive substances. Regularly wipe down the exterior with a soft cloth and mild detergent, especially after exposure to harsh environments. This helps prevent corrosion and maintains the integrity of components.

Lubrication

Ensure that all moving parts are adequately lubricated according to the manufacturer’s guidelines. Proper lubrication reduces friction, minimizes wear, and enhances the cylinder’s operational efficiency.

Hydraulic Fluid Checks

Regularly check the hydraulic fluid levels and quality. Maintain the recommended fluid type and replace it as necessary to prevent contamination that could impair performance.

Torque Checks

Periodically verify that all bolts and connections are secure and torqued to the manufacturer’s specifications. Loose fittings can lead to leaks and operational failures.

Functionality Testing

Perform functionality tests to ensure the cylinder operates smoothly. Check for any unusual noises, vibrations, or changes in performance during operation, which could indicate underlying issues.

Documentation

Maintain a detailed maintenance log that records inspections, repairs, and any incidents. This documentation helps in tracking performance trends and planning future maintenance.

Professional Servicing

Schedule regular professional servicing or assessments by qualified technicians. They can provide expertise in identifying potential issues and ensuring compliance with safety standards.

By following these maintenance practices, operators can ensure the HCYY11112006 lifting cylinder remains in peak condition, enhancing safety and reliability during aerial operations.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: