Aerial Work Platform Luffing Cylinder

Som en av produsentene, leverandørene og eksportørene av mekaniske produkter tilbyr vi hydrauliske sylindere og mange andre produkter.

Ta kontakt med oss for mer informasjon.

Post:sales@hydraulic-cylinders.net

Produsent, leverandør og eksportør av hydrauliske sylindere.

Aerial Work Platform Luffing Cylinder

The aerial work platform luffing cylinder is a vital component in aerial work platforms, designed to enhance safety and efficiency in elevated work environments. This innovative hydraulic cylinder provides controlled vertical movement, allowing for precise lifting and lowering of the platform.

The aerial work platform luffing cylinder is a crucial component in aerial work platforms, providing controlled vertical movement and enhancing safety and efficiency in elevated work environments. With its precise lifting capabilities, high load capacity, and integrated safety features, this cylinder empowers operators to work at different heights confidently. By following the recommended usage methods and maintenance practices, operators can maximize the lifespan and performance of the aerial work platform luffing cylinder, resulting in increased productivity, reduced downtime, and enhanced safety in elevated work applications. Invest in this advanced hydraulic component to elevate your aerial work platform’s capabilities and take your eloquent work to new heights of success.

Aerial Work Platform Luffing Cylinder Key Characteristics:

- Controlled Vertical Movement:

- The aerial work platform luffing cylinder offers precise and controlled vertical movement, enabling operators to adjust the working height of the platform with accuracy and ease.

- It provides smooth and stable lifting and lowering actions, ensuring a secure and comfortable working environment at different heights.

- High Load Capacity:

- This cylinder boasts a high load capacity, allowing it to support heavy loads and accommodate multiple workers, tools, and equipment on the aerial work platform.

- It provides reliable lifting performance, maintaining stability and safety even with substantial payloads.

- Compact and Robust Design:

- The aerial work platform luffing cylinder features a compact design, minimizing the overall weight and footprint of the aerial work platform.

- Its robust construction ensures durability and longevity, withstanding the demanding conditions of elevated work environments.

- Integrated Safety Features:

- This cylinder has integrated safety features like overload protection and emergency lowering systems.

- These safety mechanisms provide additional peace of mind, safeguarding against potential accidents and facilitating a quick response during emergencies.

Aerial Work Platform Luffing Cylinder Parameter:

| Product Name | Aerial Work Platform Luffing Cylinder |

| Features: | Realizing the up-and-down pitching rotation of the boom is the main driving force for lifting |

| Bore diameter: | 50mm~350mm |

| Rod diameter: | 30mm~300mm Stroke≤3000 mm |

| Pressure: | 30MPa(Maximum pressure) |

| Luffing Cylinder Applications: | Aerial Work Platform |

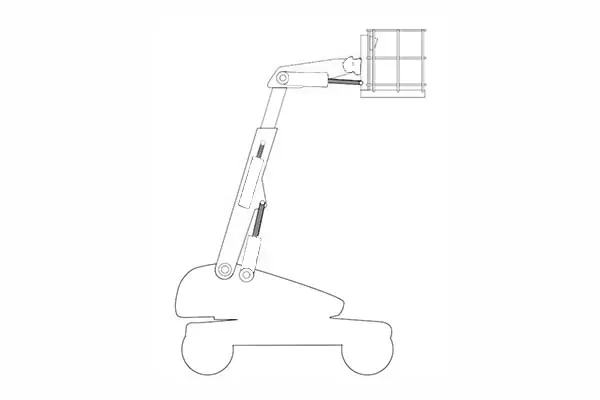

Aerial Work Platform Identification Diagram:

Usage Method Of Aerial Work Platform Luffing Cylinder:

- Cylinder Installation:

- Follow the manufacturer’s instructions for properly installing the aerial work platform luffing cylinder.

- Ensure the cylinder is securely mounted to the aerial work platform’s structure, providing a stable and reliable connection.

- Hydraulic Connection:

- Connect the cylinder to the hydraulic system of the aerial work platform according to the provided guidelines.

- Ensure that all hydraulic connections are secure and properly sealed to prevent any leaks or loss of hydraulic fluid.

- Control Activation:

- Utilize the platform’s control panel or interface to activate the aerial work platform luffing cylinder.

- Follow the recommended operating procedures to lift or lower the platform to the desired height.

- Safety Precautions:

- Before operating the aerial work platform, familiarize yourself with the safety features and emergency procedures.

- Ensure that all operators receive proper training on the safe operation of the platform and the aerial work platform luffing cylinder.

How To Get Water Out Of Tractor Hydraulic System?

Getting water out of a tractor’s hydraulic system is essential to maintain the system’s performance and prevent damage. Here’s a step-by-step guide on how to remove water from a tractor hydraulic system:

- Identify the Water Contamination:

- Check for signs of water contamination, such as milky or cloudy hydraulic fluid, reduced system performance, or water droplets in the reservoir.

- Confirm that water is the cause of the issue by ruling out other potential problems.

- Drain the Hydraulic System:

- Locate the drain plug or valve on the hydraulic reservoir or tank.

- Place a suitable container or drain pan beneath the drain plug to catch the fluid.

- Open the Drain Plug:

- Carefully loosen and remove the drain plug or open the valve using an appropriate wrench or tool.

- Allow the contaminated hydraulic fluid to drain completely from the system.

- Dispose of the contaminated fluid according to local regulations.

- Flush the System:

- Once the hydraulic fluid is drained, flush the system with a suitable flushing agent or clean hydraulic fluid.

- Follow the manufacturer’s recommendations for the appropriate flushing agent and procedure.

- Connect a hose to the hydraulic system’s inlet and use it to pump the flushing agent or clean fluid through the system.

- Let the flushing agent circulate through the system sufficiently to dislodge any remaining water.

- Drain the Flushing Agent:

- Open the drain plug or valve again to drain the flushing agent from the system.

- Allow the flushing agent to drain completely into the container or drain pan.

- Refill with Clean Hydraulic Fluid:

- Close the drain plug or valve once all the flushing agent has been drained.

- Refill the hydraulic system with clean, recommended hydraulic fluid.

- Follow the manufacturer’s guidelines for the appropriate fluid type and fill level.

- Bleed the System:

- Bleed any air from the hydraulic system according to the manufacturer’s instructions or bleed procedures specific to your tractor model.

- This step ensures proper hydraulic system operation and eliminates any air pockets.

- Test the System:

- Start the tractor and engage the hydraulic system.

- Check for any abnormal noises, leaks, or performance issues.

- Operate the hydraulic system to verify that it functions smoothly without water-related problems.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best hydraulic cylinder manufacturers. We can offer comprehensive hydraulic cylinders. We also provide corresponding agricultural gearboxes. We have exported our products to clients worldwide and earned a good reputation because of our superior product quality and after-sales service. We welcome customers at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: