HOB/HOD Heavy Rod Hydraulic Cylinder

Som en av produsentene, leverandørene og eksportørene av mekaniske produkter tilbyr vi hydrauliske sylindere og mange andre produkter.

Ta kontakt med oss for mer informasjon.

Post:sales@hydraulic-cylinders.net

Produsent, leverandør og eksportør av hydrauliske sylindere.

HOB/HOD Heavy Rod Hydraulic Cylinder

The HOB heavy rod hydraulic cylinder is a double-acting cylinder; The front and rear cylinder heads are connected by four screws, disassembly, and maintenance, and are often used in the mold and packaging machinery industry. Standard hob heavy rod hydraulic cylinder uses pressure 14Mpa, test pressure 21Mpa because the pressure is medium and high pressure, the strength of each part of the cylinder is sufficient.

Product Performance And Characteristics:

Grease-free: The product uses oil-containing self-lubricating bearings so that the piston rod does not need to be lubricated;

Adjustable Buffer: The cylinder terminal is also equipped with an elastic buffer, which is stable and has no impact when the cylinder is reversed (customers need to order special instructions from the company);

Variety Of Installation Forms: A variety of installation accessories for customers to choose from according to use requirements;

High-temperature Resistance: High-temperature resistant sealing material can be used to make the cylinder work typically under high-temperature conditions of 180°C (customers need to order special instructions from the company);

Magnetic: The cylinder piston is equipped with a permanent magnet, which can trigger the induction switch installed on the cylinder to sense the moving position of the cylinder (customers need to order special instructions from the company);

Stroke adjustability: The piston rod end is equipped with an adjustable nut, which makes the cylinder flexible within its stroke range (thrust F1= pull F2);

Derivative Diversity: Diversified non-standard products can be derived based on the original to suit the various use requirements of customers.

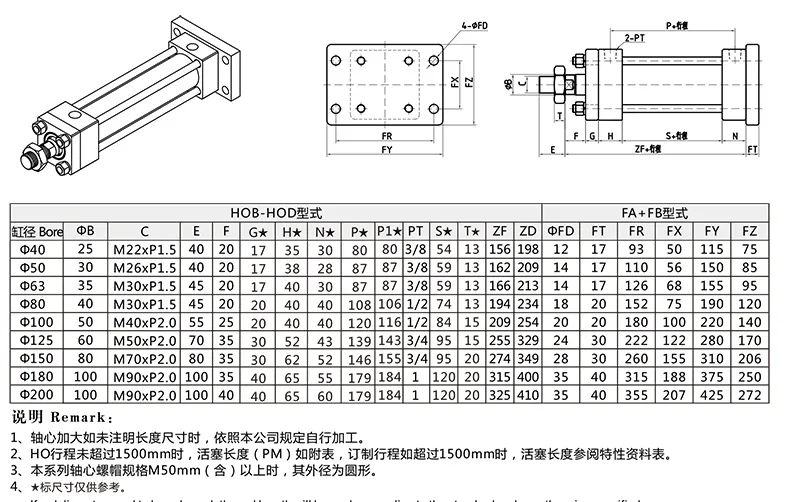

HOB/HOD Heavy Rod Hydraulic Cylinder Parameter:

(1)Standard Heavy Rod Hydraulic Cylinder

(2) FA Front Flange Type Heavy Rod Hydraulic Cylinder

(3)FB Rear Flange Type Heavy Rod Hydraulic Cylinder

(4)TA Front Trunnion Type Heavy Rod Hydraulic Cylinder

(5)TC Middle Trunnion Type Heavy Rod Hydraulic Cylinder

(6)LA Left And Right Foot Type Heavy Rod Hydraulic Cylinder

(7)LB Front And Back Foot Type Heavy Rod Hydraulic Cylinder

(8)CA Monaural Type Heavy Rod Hydraulic Cylinder

(9) CB Type Binaural Type Heavy Rod Hydraulic Cylinder

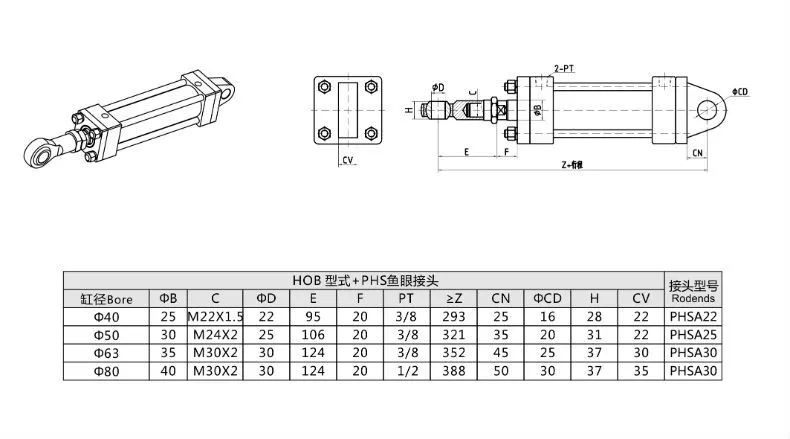

(10) CA Monaural Type Phs Fisheye Connector Heavy Rod Hydraulic Cylinder

(11) CA Monaural Type Gksk Joint Earring Connector Heavy Rod Hydraulic Cylinder

(12) CA Monaural Type Y Connector Heavy Rod Hydraulic Cylinder

(13) Standard Biaxial Type Heavy Rod Hydraulic Cylinder

(14) Biaxial Type With Adjustable Nuts Heavy Rod Hydraulic Cylinder

(15) FA Double Shaft Front Flange Type Heavy Rod Hydraulic Cylinder

HOB Heavy Rod Hydraulic Cylinder Model Description:

HOBD-63/35*100+LB+Y

HOB — Type: HOB= standard HOD= biaxial type

D– Buffer type: No mark = no D= bilateral F= front cover side B= rear cover side

63– Cylinder diameter: Φ40, Φ50, Φ63, Φ80, Φ100, Φ125, Φ150, Φ180, Φ200

35– Rod diameter:

Axis standard: Φ25, Φ30, Φ35, Φ40, Φ50, Φ60, Φ80, Φ100, Φ100

Maximum axis: -Φ35, Φ40, Φ50, Φ60, Φ80, Φ100, Φ120, Φ120

Buffer axis standard: Φ18, Φ25, Φ30, Φ40, Φ50, Φ60, Φ80, Φ100, Φ100

Unmarked: Standard axis

100– Itinerary:

Standard Travel (mm): 50,100,510,200,250,300,350,400,450,500,600,700,800,900,1000

LB– Cylinder Block Fixing Mode: FA= front flange type FB= back flange type LB= foot seat type TC= transom type LA= foot seat type CA= single ear type CB= Double ear type CBP CB with PIN CAB CA+P+CB

Y– Axis Fixed Mode: Y=Y type joint YP=Y with PIN I=I type joint KG= floating joint PHS= fisheye joint T=T type joint H= welded sleeve joint A= adjustable nut

HOB Heavy Rod Hydraulic Cylinder Characteristics:

HOB Heavy Rod Hydraulic Cylinder Composition:

The HOB heavy-duty tie rod hydraulic cylinder consists of a press plate, front cylinder head, back cylinder head, piston, cylinder, piston rod, 4 screw rods, 8 lock nuts and gaskets, 1 piston lock nut and gasket, 1 piston rod end matching lock nut, a full set of seals, tie rod end protective cover, oil plug.

The front and back covers are made of No. 45 cylinder material, the piston rod is No. 45 chromium-plated layer thickness 2-3 wires, the cylinder barrel is No. 20 rolled tube, and the tie rod material is A3(with No. 45 tempered for large cylinder diameter). The seal adopts Taiwan DZ brand.

HOB Heavy Rod Hydraulic Cylinder 100% Oil Test:

The oil test is carried out on the test bench. The steps are as follows: the oil import and export of the oil pipe and cylinder of the test bed, the pressure on the test bed, the oil of the test bed into the cylinder, the cylinder is reversed by the solenoid valve so that the cylinder can go back and forth several times, and the gap between the rod end of the cylinder, the cylinder and the front and back cover to observe whether there is oil leakage.

Test pressure =14Mpa*21=10.5Mpa. Check whether the cylinder has been tested; It’s straightforward. After connecting the oil cylinder, remove the plug of the oil port to see if there is an oil trace. There are traces of oil, indicating that oil testing has been done.

HOB Heavy Rod Hydraulic Cylinder Details Display:

1. The inner hole is manufactured by rolling or honing precision machining technology, so that the piston and its seals and supporting parts can slide smoothly, to ensure the sealing effect and reduce wear.

2. Chromium plating layer thickness 2-3 wire, good wear resistance, not easy to rust, can withstand 72 hours salt spray test.

3. Cylinder head -45 forging parts, screw -45 tempering, to ensure the strength of the cylinder

4. The cylinder head is blackened, the milling edge is smooth, the chamfer is uniform, and the wrench position design is convenient and practical

5. Use ductile iron guide rail to increase wear resistance

6. Perform a pressure test before departure

7. Imported oil seal, brand products, one-year warranty

How Do You Rebuild A Hydraulic Cylinder?

Rebuilding a hydraulic cylinder involves disassembling the cylinder, inspecting and replacing worn or damaged components, and reassembling the cylinder with new seals and other necessary parts. Here is a general step-by-step guide on how to rebuild a hydraulic cylinder:

- Safety Precautions: Before starting the rebuild process, ensure that the hydraulic system is depressurized and that all hydraulic fluid has been drained. Wear appropriate safety gear, such as gloves and safety glasses, to protect yourself.

- Cylinder Removal: Disconnect the hydraulic cylinder from the equipment or machinery it is attached to. This may involve removing mounting brackets, fittings, or other connections. Follow the manufacturer’s instructions or equipment manuals for guidance specific to your hydraulic cylinder.

- Disassembly: Carefully disassemble the hydraulic cylinder, following these steps:a. Remove the end caps: Typically, hydraulic cylinders have two end caps—one at each end. Unscrew the bolts or screws holding the end caps in place and carefully remove the caps.b. Extract the piston: Once the end caps are removed, gently slide out the piston assembly from the cylinder barrel. Take note of the orientation and arrangement of any seals or bearings.

c. Remove seals and other components: Remove all seals, bearings, and any other components from both the piston and cylinder barrel. Inspect each component for wear, damage, or signs of leakage.

- Inspection and Replacement: Inspect all components, including the piston, cylinder barrel, seals, bearings, and other parts. Look for signs of wear, scoring, pitting, or other damage. Replace any components that show signs of excessive wear or damage.a. Seals: Replace all seals with new ones, ensuring they are the correct size and type for your hydraulic cylinder. Lubricate the new seals with hydraulic fluid before installation.b. Other Components: If any bearings, bushings, or other components show signs of wear or damage, replace them with new ones per the manufacturer’s specifications.

- Cleaning: Clean all components thoroughly, removing dirt, debris, or old hydraulic fluid. Use a suitable cleaning agent to ensure all parts are completely dry before reassembly.

- Reassembly: Follow these steps to reassemble the hydraulic cylinder:a. Install new seals: Carefully install new seals onto the piston and inside the cylinder barrel. Ensure proper orientation and alignment of the seals.b. Insert the piston: Gently slide the piston assembly back into the cylinder barrel, taking care not to damage the new seals.

c. Reattach end caps: Place the end caps back onto the cylinder barrel and secure them with the appropriate bolts or screws. Tighten them to the manufacturer’s recommended torque specifications.

- Hydraulic Fluid Replacement: Fill the hydraulic cylinder with the recommended hydraulic fluid, ensuring it is the correct type and at the appropriate level. Bleed any air from the system as per the manufacturer’s instructions.

- Testing: Reconnect the hydraulic cylinder to the equipment or machinery and test its operation. Check for any leaks or abnormal behavior. Ensure that the cylinder functions smoothly and performs as expected.

Capability & Capacity Of Factory:

(1) Assembly

We have a first-class independent research and development assembly platform. The hydraulic cylinder production workshop has four semi-automatic lifting cylinder assembly lines and one automatic tilt cylinder assembly line, with a designed annual production capacity of 1 million pieces. The special cylinder workshop is equipped with various specifications of a semi-automatic cleaning assembly system with a designed annual production capacity of 200,000 and equipped with famous CNC machining equipment, a machining center, a high-precision cylinder processing special equipment, a robot welding machine, an automatic cleaning machine, automatic cylinder assembly machine, and automatic painting production line. Existing critical equipment of more than 300 sets (sets). The optimal allocation and efficient use of equipment resources ensure the accuracy requirements of products and meet the high-quality needs of products.

(2) Machining

The machining shop is equipped with a customized inclined rail turning center, machining center, high-speed honing machine, welding robot, and other related equipment, which can handle the processing of cylinder tubes with a maximum inner diameter of 400mm and a maximum length of 6 meters.

(3) Welding

(4) Painting & coating

With small and medium-sized cylinder automatic water-based paint coating lines, to achieve automatic robot loading and unloading and automatic spraying, the design capacity of 4000 pieces per shift;

We also have a semi-automatic paint production line for large cylinders powered by a power chain, with 60 cases per shift design capacity.

(5) Testing

We have first-class inspection facilities and test beds to ensure that the performance of the cylinder meets the requirements.

We are one of the best heavy rod hydraulic cylinder manufacturers. We can offer wide heavy rod hydraulic cylinder stock. We also provide corresponding agricultural gearboxes. We have exported our products to clients around the world and earned a good reputation because of our superior product quality and after-sales service. We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information, and cooperate with us!

Take a Tour of Our VR Factory:

Take a tour of our VR factory with the following

How Does Forklift Hydraulic Cylinder Work?

Hydraulic Cylinder Application: