Replacement Of A89414 Hydraulic Cylinder End

Kā viens no hidraulisko cilindru ražotājiem, piegādātājiem un eksportētājiem, mēs piedāvājam hidrauliskos cilindrus un daudzus citus produktus.

Lūdzu, sazinieties ar mums, lai saņemtu sīkāku informāciju.

Pasts:sales@hydraulic-cylinders.net

Hidraulisko cilindru ražotājs, piegādātājs, eksportētājs.

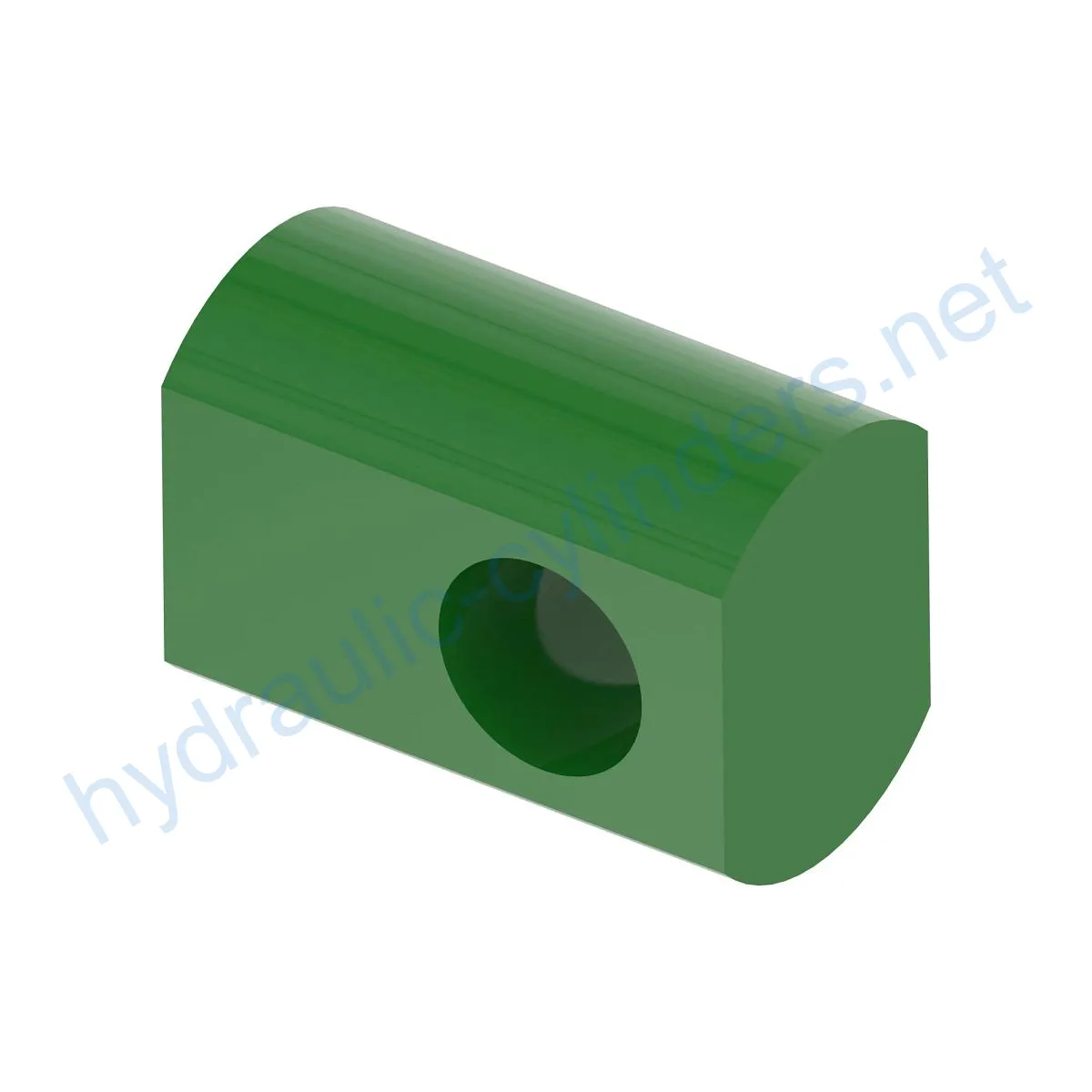

Replacement of A89414 Hydraulic Cylinder End

Hydraulic cylinder is an important component in various hydraulic systems. It converts the energy of hydraulic fluid into mechanical force to move or lift machinery and equipment. The Replacement of A89414 Hydraulic Cylinder End is designed to replace damaged or worn hydraulic cylinders, restoring the normal operation of equipment and ensuring its performance in various applications.

Specifications and Models

The Replacement of A89414 Hydraulic Cylinder End has a weight of 12.02 lb, a height of 3 in, a width of 4 in, a length of 5.5 in, and a screw size of 2 in. It is compatible with the following machine models: 1890, N550, and N560.

Features

Improves Equipment Performance

By replacing damaged or worn hydraulic cylinders, the equipment’s normal operation can be restored, ensuring its performance in various applications.

Enhances Safety

Regular replacement of hydraulic cylinders can reduce safety hazards caused by cylinder failures, ensuring the safety of operators and equipment.

Offers Overload Protection

New cylinder designs usually consider better overload protection mechanisms, improving safety.

Enables Quick Installation

Modern hydraulic cylinder designs typically consider easy installation and replacement, reducing downtime.

Standardizes Parts

Many hydraulic cylinders are standardized products, making it easier to obtain replacement parts in the market.

Applications

The Replacement of A89414 Hydraulic Cylinder End can be used in various equipment, including but not limited to:

- Excavators: for the arm or bucket of the excavator

- Cranes: for the boom of the crane

- Tractors: for the front-end loader of the tractor

- Harvesters: for the hydraulic systems in the harvester

- Automated production lines: for controlling robotic arms and other automation equipment

- Die-casting machines: used in high-pressure and high-temperature environments

- Mining equipment: for lifting and moving heavy objects in the mining industry

- Bulldozers: for the dozer blade of the bulldozer

Maintenance

To ensure the longevity and proper function of the Replacement of A89414 Hydraulic Cylinder End, regular maintenance is crucial. The following three maintenance tasks are recommended:

Regular Inspection

Periodically inspect the hydraulic cylinder to ensure that it is functioning properly and identify any signs of wear or damage.

Appropriate Lubrication

The cylinder requires appropriate lubrication to prevent friction and wear. Use the recommended lubricants and follow the proper lubrication procedures.

Seal Replacement and Calibration Check

Periodically replace the seals and inspect the cylinder’s calibration to ensure its proper function.

Safety Considerations and Environmental Factors

When working with hydraulic systems, safety should be a top priority. It is essential to follow proper safety procedures and use appropriate safety gear. Additionally, environmental factors, such as temperature and moisture, can affect the function of hydraulic cylinders.

Troubleshooting and Common Problems

If the hydraulic cylinder is not functioning properly, it is important to diagnose the problem and implement the appropriate solution. Common problems include leaks, insufficient force, and inaccurate calibration.

Product Design and Selection Criteria

The design of hydraulic cylinders is crucial to their function and longevity. Key factors to consider in the design include load capacity, sealing, durability, safety, and maintenance. Proper selection of hydraulic cylinders can ensure they meet the specific needs of the application.

Seal and Lubrication

The seals and lubrication of hydraulic cylinders are essential for proper function and longevity. Use quality seals and lubricants, and follow proper lubrication procedures, such as regular oil changes and calibration checks.

Installation Guide

To ensure proper installation of the Replacement of A89414 Hydraulic Cylinder End, follow these steps:

- Align the cylinder with the equipment and secure it with appropriate mounting brackets.

- Connect the hydraulic hoses to the cylinder’s ports and tighten them securely.

- Fill the cylinder with the recommended hydraulic fluid and bleed the system to remove any air bubbles.

About Our Company

We are a leading manufacturer and wholesaler of hydraulic cylinders, offering a wide range of products to meet the needs of various industries. Our company is committed to providing high-quality products, professional service, and customized solutions to our customers worldwide. We have obtained international certifications and have state-of-the-art production facilities, ensuring the quality and reliability of our products. Our after-sales service includes replacement parts and rebuilding services, ensuring the longevity and proper function of our products.

Author: lyl

Dodieties ekskursijā uz mūsu VR rūpnīcu:

Dodieties ekskursijā uz mūsu VR rūpnīcu ar šādiem elementiem.

Kā darbojas autoiekrāvēja hidrauliskais cilindrs?

Hidrauliskā cilindra pielietojums: