HCYY11112026 Behind Cylinder For Opening Rack Support For Truck Cranes

Kā viens no hidraulisko cilindru ražotājiem, piegādātājiem un eksportētājiem, mēs piedāvājam hidrauliskos cilindrus un daudzus citus produktus.

Lūdzu, sazinieties ar mums, lai saņemtu sīkāku informāciju.

Pasts:sales@hydraulic-cylinders.net

Hidraulisko cilindru ražotājs, piegādātājs, eksportētājs.

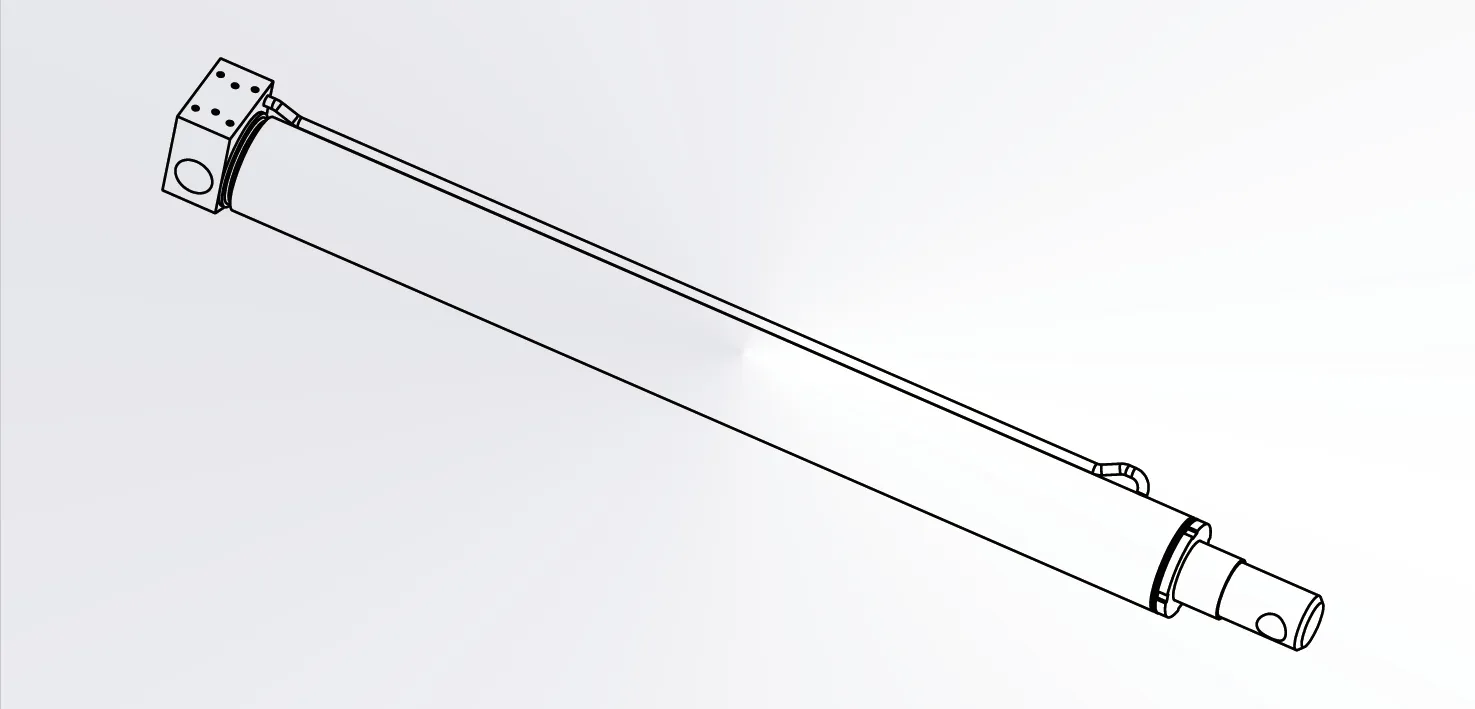

HCYY11112026 Behind Cylinder For Opening Rack Support For Truck Cranes

The HCYY11112026 Behind Cylinder is a vital component specifically designed for truck cranes, providing robust support for the opening rack. This high-performance cylinder significantly enhances the crane’s stability and operational efficiency during lifting tasks, making it an invaluable asset across various industrial applications.

With its impressive load capacity, durable construction, and corrosion resistance, the HCYY11112026 excels in demanding lifting scenarios. By adhering to proper usage methods and maintenance guidelines, operators can ensure this cylinder delivers reliable performance for years.

Investing in the HCYY11112026 not only boosts operational efficiency but also improves safety on the job site, making it an excellent choice for any crane operation.

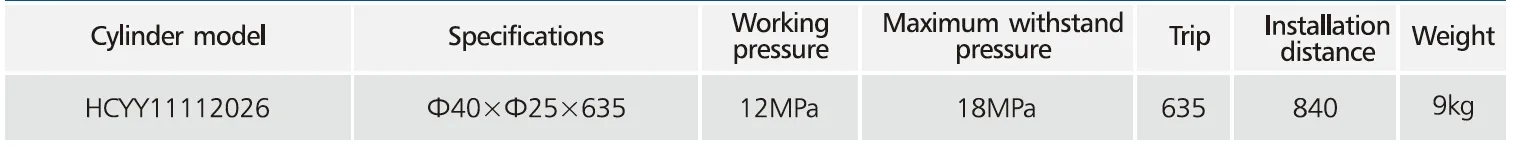

HCYY11112026 Behind Cylinder For Opening Rack Support For Truck Cranes Parameter:

Cylinder Series For Truck Cranes:

Key Features of HCYY11112026 Behind Cylinder For Opening Rack Support For Truck Cranes:

High Load Capacity

The HCYY11112026 is meticulously engineered to support substantial weights, making it a reliable choice for heavy lifting scenarios. Designed with advanced engineering techniques, this cylinder ensures that even the most demanding loads are handled with ease. Operators can trust its strength and stability, enhancing overall productivity and safety during operations.

Durable Construction

Constructed from high-quality materials, the HCYY11112026 cylinder is built to withstand the rigors of frequent use. Its robust design minimizes wear and tear, ensuring longevity and reducing the need for frequent replacements. This durability translates into lower maintenance costs and increased operational uptime, making it a smart investment for any crane operation.

Corrosion Resistance

Equipped with a specialized coating, the HCYY11112026 offers exceptional protection against rust and corrosion. This feature is particularly advantageous in challenging environments, such as those exposed to moisture or harsh chemicals. By maintaining its integrity over time, the cylinder ensures consistent performance and reliability, even in the toughest conditions.

Precision Engineering

Manufactured to exact specifications, the HCYY11112026 guarantees optimal compatibility with a wide range of truck crane models. This precision engineering not only ensures a perfect fit but also enhances the overall efficiency of the crane’s operations. Operators can confidently integrate this cylinder into their existing systems, knowing it will perform seamlessly.

Easy Installation

The design of the HCYY11112026 allows for quick and straightforward installation, minimizing downtime during setup. Clear guidelines and user-friendly features enable operators to integrate the cylinder into their crane systems without hassle. This ease of installation means that cranes can quickly return to service, maximizing productivity on the job site.

The HCYY11112026 Behind Cylinder stands out as a high-performance component that significantly enhances truck crane operations. Its high load capacity, durable construction, corrosion resistance, precision engineering, and ease of installation make it an exceptional choice for any lifting task. Investing in this cylinder not only boosts efficiency but also enhances safety and reliability, making it an indispensable asset for modern crane operations.

How Does The Hcyy11112026 Behind Cylinder Improve The Stability Of Truck Cranes During Lifting Operations?

The HCYY11112026 Behind Cylinder plays a crucial role in enhancing the stability of truck cranes during lifting operations through several key mechanisms:

1. Weight Distribution

The cylinder is expertly designed to facilitate even weight distribution across the crane’s frame. By spreading the load more uniformly, it prevents excessive stress on any single point. This balanced load management is vital when handling heavy or unevenly distributed loads, reducing the risk of structural failure and enhancing overall safety.

2. Structural Reinforcement

By providing solid support for the opening rack, the HCYY11112026 reinforces the crane’s overall structure. This added reinforcement minimizes flexing and bending, which can occur during heavy lifts. As a result, the crane remains stable and secure, significantly lowering the likelihood of accidents during operation.

3. Shock Absorption

One of the standout features of the HCYY11112026 is its ability to absorb shocks and vibrations that can arise during lifting. This shock absorption reduces the impact on the crane’s structure, contributing to smoother operations. By mitigating sudden jolts, the cylinder helps maintain stability, especially when maneuvering or repositioning heavy loads.

4. Enhanced Control

With its reliable support, the cylinder empowers operators to execute precise movements while lifting. This improved control is particularly beneficial in complex lifting scenarios where accuracy is paramount. By maintaining stability, the HCYY11112026 reduces the risk of tipping or losing balance, ensuring that operators can perform tasks confidently and efficiently.

5. Safety Assurance

Stability is synonymous with safety in crane operations. The HCYY11112026 significantly reduces the risk of accidents by maintaining a steady lifting environment. By minimizing the chances of tipping, swaying, or unexpected movements, it creates a safer working atmosphere for operators and bystanders alike. This assurance allows teams to focus on their tasks without the constant worry of potential hazards.

In summary, the HCYY11112026 Behind Cylinder is an indispensable component that significantly enhances the stability of truck cranes during lifting operations. Through effective weight distribution, structural reinforcement, shock absorption, improved control, and enhanced safety, this cylinder not only boosts operational efficiency but also fosters a safer working environment. Investing in the HCYY11112026 is a strategic choice for any operation looking to enhance the reliability and safety of their lifting equipment.

Forklift Cylinder Production Area:

We boast a state-of-the-art independent R&D platform dedicated to assembly, ensuring top-tier innovation and quality in our manufacturing processes. Our forklift cylinder production workshop features four semi-automatic lifting cylinder assembly lines and a fully automatic tilting cylinder assembly line, collectively designed to produce up to one million units annually.

In addition, our specialized cylinder workshop is equipped with semi-automatic cleaning and assembly systems tailored for various specifications, with an annual production capacity of 200,000 pieces. We utilize renowned CNC equipment, machining centers, and specialized tools for high-precision cylinder processing. Our facility also includes advanced robotic welding machines, automatic cleaning systems, and fully automated cylinder assembly and painting lines. With over 300 key pieces of equipment operational, we optimize resource allocation and ensure efficient utilization, meeting stringent precision and quality standards.

Our machining shop has custom tilt guide rail turning centers, machining centers, high-speed honing machines, welding robots, and other essential equipment. This setup allows us to handle the machining of cylinder tubes with a maximum inner diameter of 400mm and lengths of up to 6 meters, further enhancing our production capabilities.

We operate a fully automatic water-based paint coating line specifically designed for small and medium cylinders, featuring automated loading, unloading, and spraying robots. This state-of-the-art system boasts a production capacity of 4,000 units per shift. Additionally, we have a semi-automatic painting line for large-scale cylinders, powered by a chain drive, with a design capacity of 60 crates per shift.

To enhance product performance and solidify our leadership in the hydraulic cylinder industry, we have partnered with ZJIMEE to establish a comprehensive performance laboratory dedicated to hydraulic cylinders, valves, and pumps. This advanced lab utilizes computer-assisted testing with electro-hydraulic technology, allowing for preset test conditions that improve accuracy and system versatility. The automated data collection process employs sensors to gather output data, such as internal leakage and load efficiency, which is then processed by a computer and converted into standard units (ml/min%).

Furthermore, to ensure the safety of our hydraulic systems, we implement state monitoring for key performance parameters, including oil temperature, liquid level, and filter device status. Our hydraulic cylinder test stand is capable of assessing “load efficiency” and “internal leakage” through precise readings. It is also equipped with a grating ruler measuring instrument that meets national standards, ensuring compliance with all testing requirements for hydraulic cylinder products.

Dodieties ekskursijā uz mūsu VR rūpnīcu:

Dodieties ekskursijā uz mūsu VR rūpnīcu ar šādiem elementiem.

Kā darbojas autoiekrāvēja hidrauliskais cilindrs?

Hidrauliskā cilindra pielietojums: